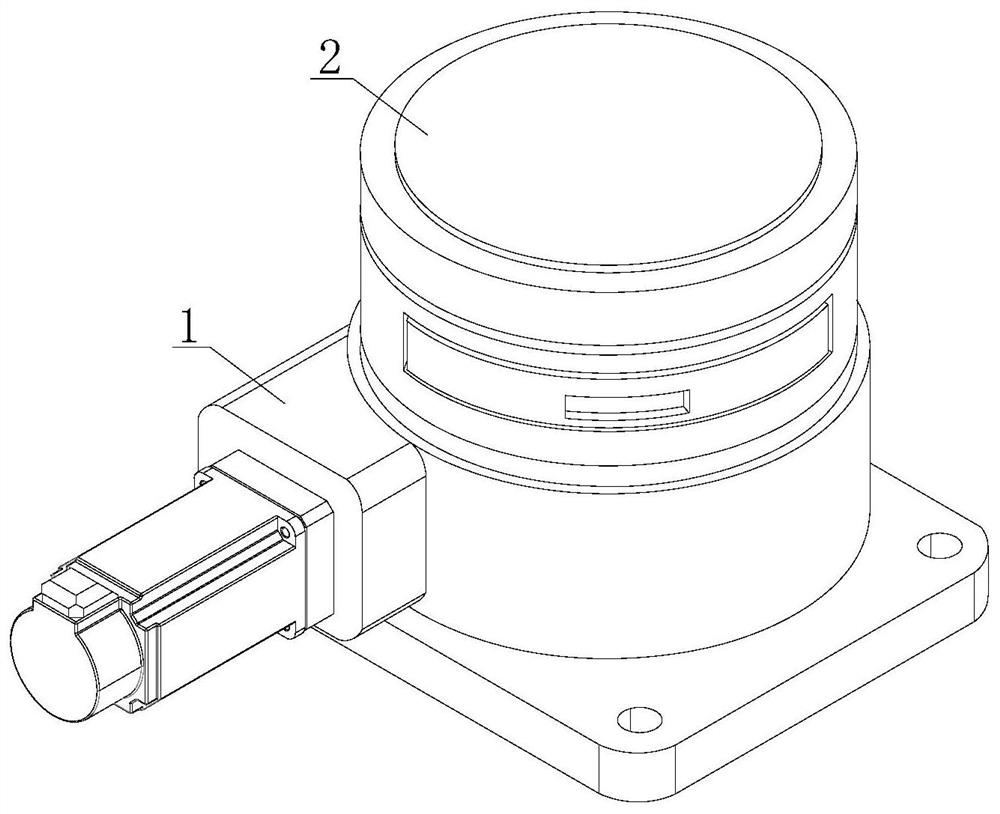

An automatic rotating disk for spraying the fixed base of communication equipment and its implementation method

A fixed base, automatic rotation technology, applied in the direction of spraying device, etc., can solve the problems of increased process, inability to rotate, small turntable area, etc., to achieve the effect of preventing wear and increasing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach , 1 Embodiment approach

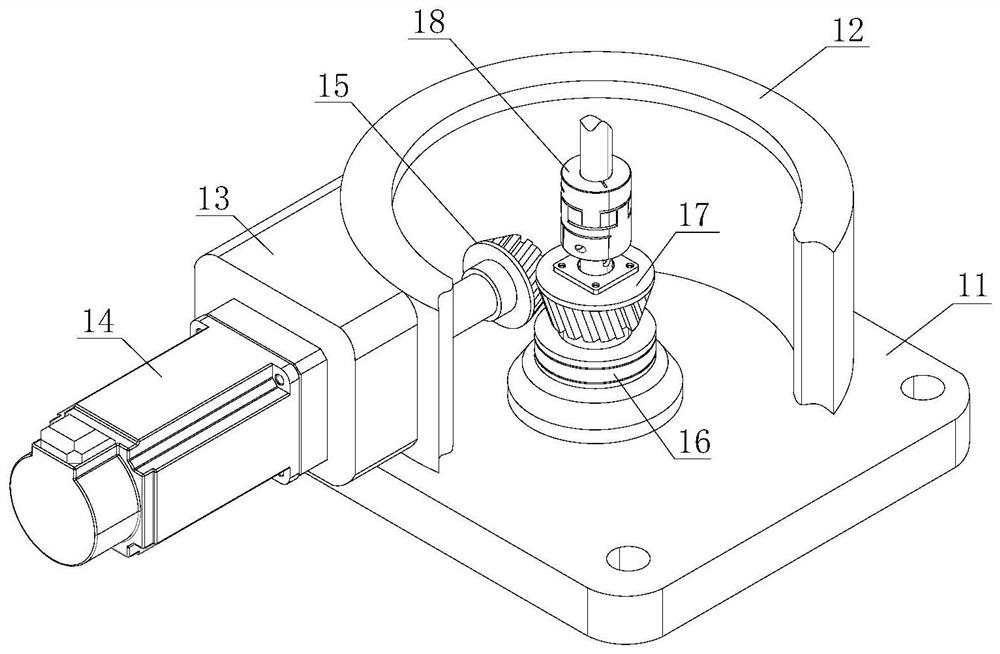

[0039] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for implementing an automatic rotating disk for spraying a fixed base of communication equipment, including the following steps:

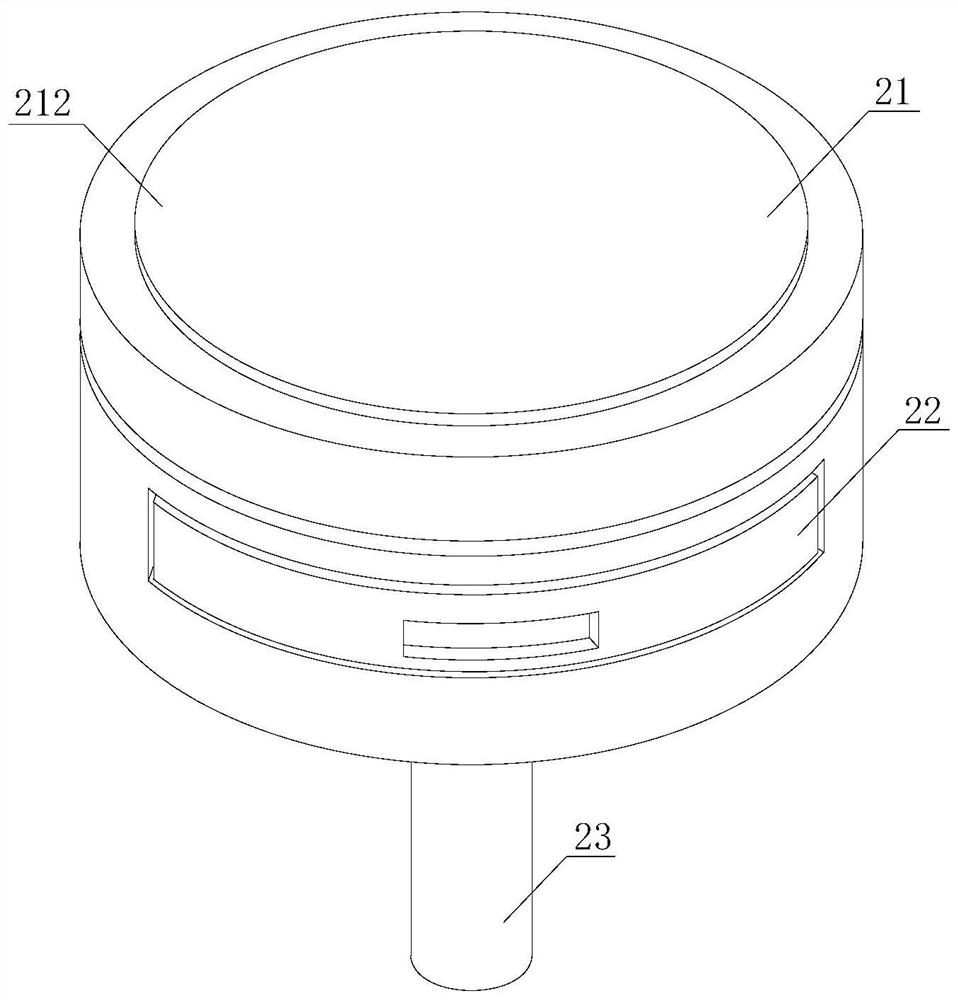

[0040] S01: place the fixed base on the upper end surface of the thickened turntable body 211;

[0041] S02: through the notch 2213, the end of the connecting rod 2221 installed with the return spring 2224 is pushed up, the other end of the connecting rod 2221 is moved down, and the limiting post 2222 is separated from the limiting hole 2113;

[0042] S03: Pull out the half-tray board 221, pull out two sets of half-tray boards 221 from the insertion slot 2111, the limit post 2222 enters the outer limit hole 2113, and place the parts for fixing the base in the half on the tray plate 221;

[0043] S04: start the driving motor 14, and drive the main turntable part 21 to rotate through the connecting shaft 23;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com