Electronic product circular shell grinding device

An electronic product, circular technology, applied in the direction of grinding drive device, grinding machine, grinding frame, etc., can solve the problem that the round shell grinding method cannot be fully ground, so as to prevent displacement, improve automation, improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

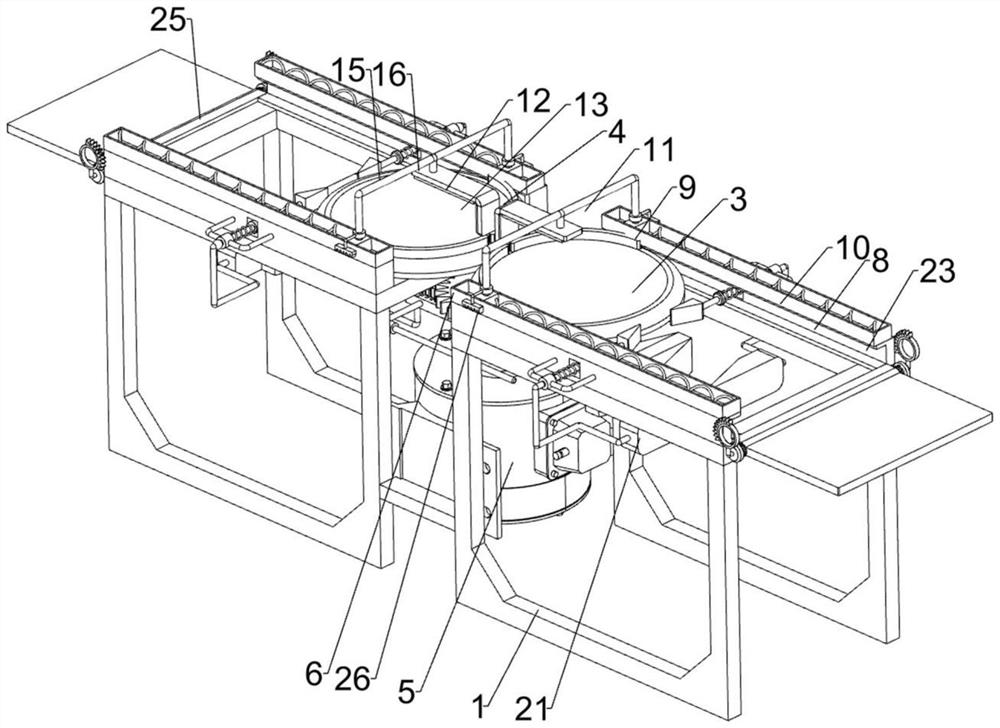

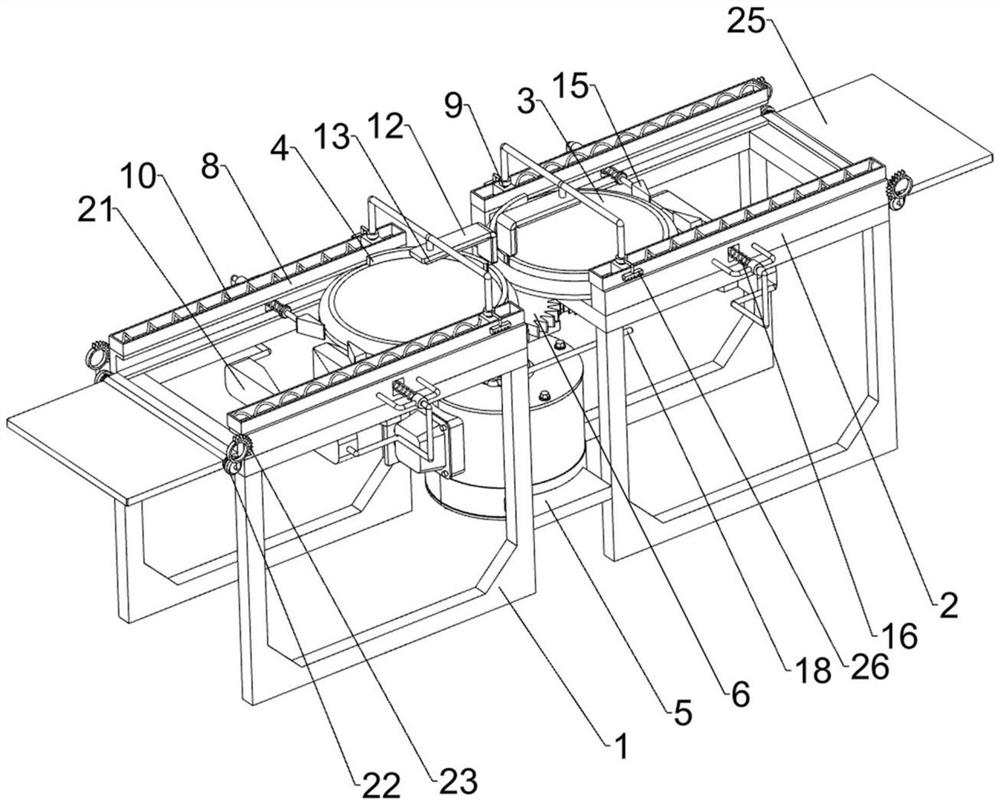

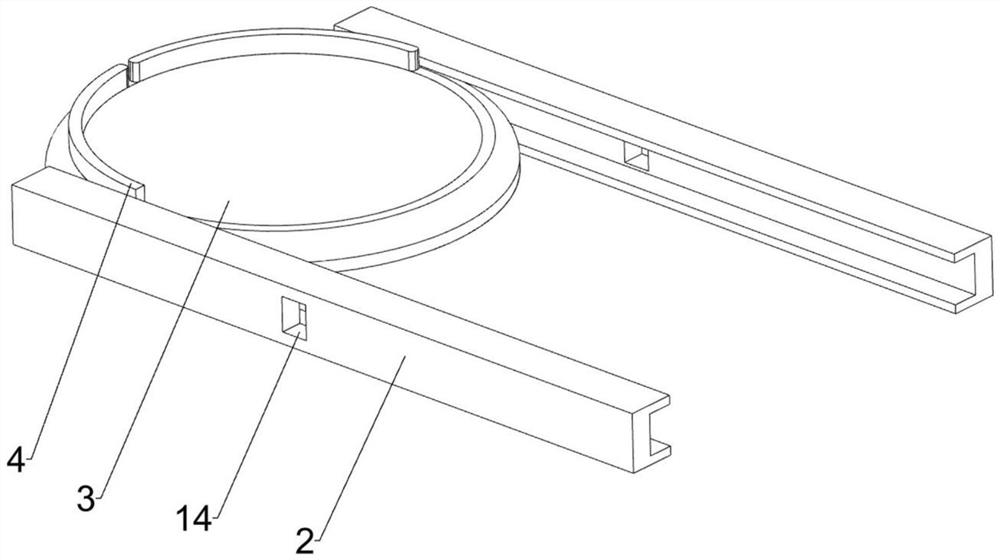

[0022] A kind of circular shell grinding device for electronic products, such as Figure 1-Figure 6 As shown, it includes a frame 1, a placement component, a grinding component and a fixing component. The frame 1 is used to install the entire device. The grinding assembly for grinding is provided with a fixed assembly fixed by sliding in the middle of the placement assembly.

[0023] When it is necessary to polish the circular housing of electronic products, the staff first places the circular housing of electronic products on the placement component, and then moves the placement component to a suitable position. At the same time, the fixing component will limit the placement of the component, and then play The grinding component grinds the round shell of the electronic product. After the shell of the electronic round part is polished, close the grinding component, and then loosen the fixing component, and the staff can move the placement component to a certain position to rem...

Embodiment 2

[0031] On the basis of Example 1, such as figure 1 , figure 2 with Figure 4 As shown, it also includes a third gear 17, an L-shaped bar 18, a long rack 19, a special-shaped block 20 and a second wedge block 21, the bottom of the second gear 7 is provided with a third gear 17, and the L-shaped bar 18 has two , the middle part of the inner side of the frame 1 is slidingly provided with an L-shaped bar 18, and the outer ends of the L-shaped bar 18 are fixedly connected with a long rack 19 by screws, and the long rack 19 meshes with the third gear 17, and the bottom of the long rack 19 is left The side is fixed with a special-shaped block 20 by bolts, and the outer ends of the first wedge-shaped block 15 are all fixedly connected with a second wedge-shaped block 21 by screws, and the second wedge-shaped block 21 cooperates with the special-shaped block 20 .

[0032] When the second gear 7 rotates, it drives the third gear 17 to rotate, pushes the long rack 19 to move outward, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com