Mold for processing latex mattress and mattress processed by using mold

A mattress and latex technology, applied in the field of bedding, can solve the problems of reducing the comfort of use and affecting the experience of use, and achieve the effect of ensuring softness, improving comfort and use experience, and balancing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

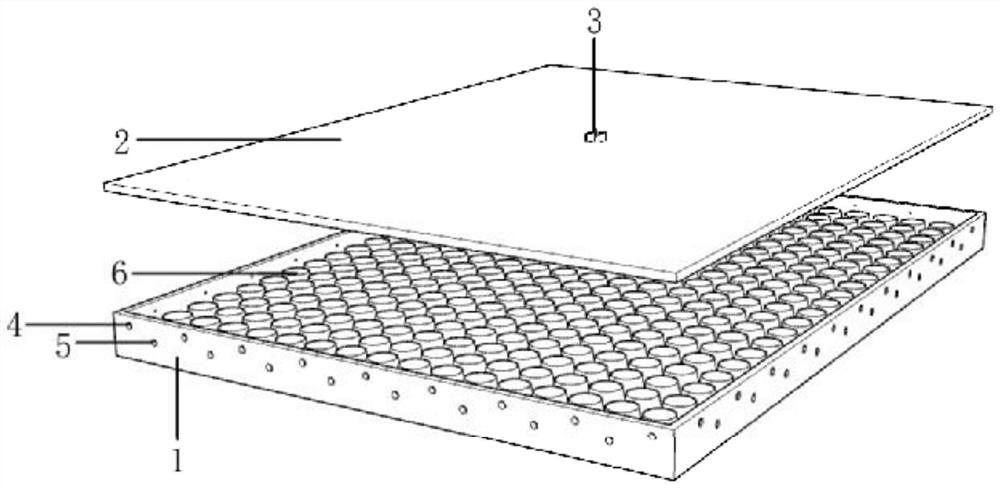

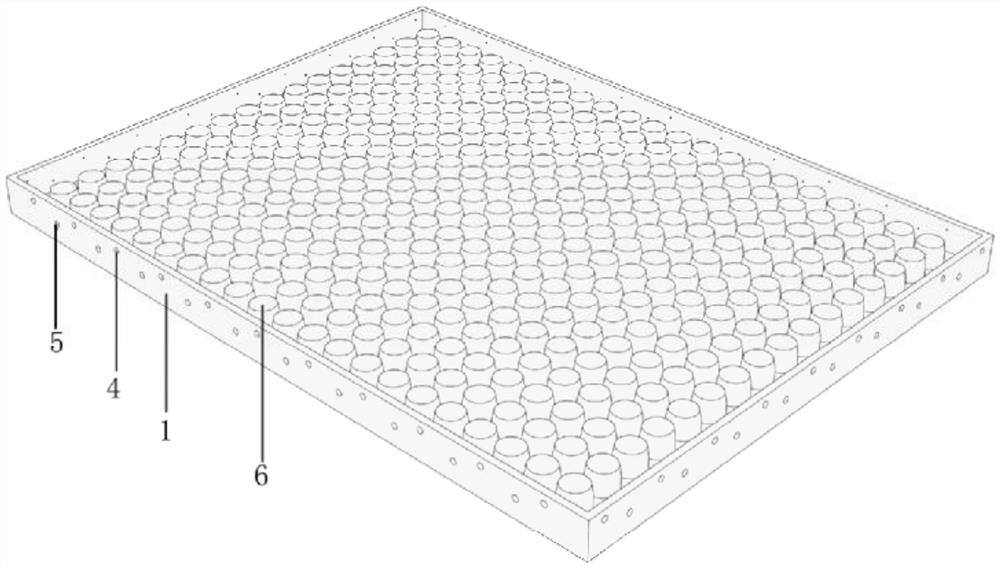

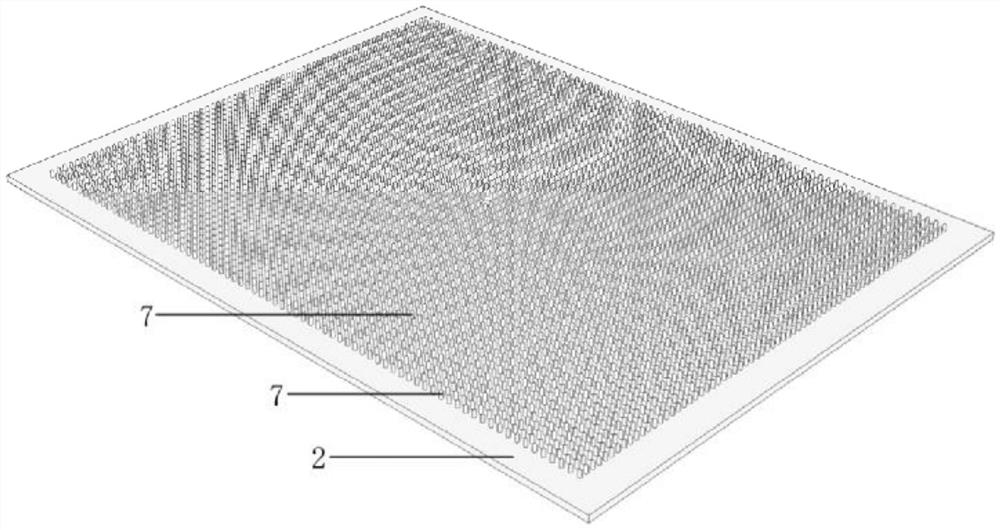

[0028] like figure 1A mold for processing latex mattresses shown is composed of a first template 1 and a second template 2. The first template 1 and the second template 2 are aligned and joined together to form a mold cavity. The top of the mold cavity The middle part of the surface is provided with a glue injection hole 3, and the upper edge and the lower edge of the outer peripheral wall of the mold cavity are respectively provided with a residual material discharge hole 4 and a decompression discharge hole 5, and the decompression discharge pressure of the decompression discharge hole 5 is greater than that of the remaining material. When the raw material fills the mold cavity through the glue injection hole 3 and discharges the remaining material through the glue discharge hole 4, the raw material at the bottom o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com