Preparation method of knitted collar with anti-curling characteristic

A collar and characteristic technology, applied in the collar field, can solve problems such as wrinkles, poor shape, and failure to keep the collar flat and stiff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A method for preparing a knitted collar with anti-curling characteristics, first knitting a collar with thermoplastic elastomer yarn introduced into the collar corner area, and then compressing and heat-setting the collar as a whole to obtain anti-curling characteristics knitted collar;

[0068] Weaving uses three yarn feeders, one yarn feeder A wears the main yarn (3 yarns 36 S cotton and hemp blended yarn, the mass ratio of cotton and hemp is 7:3), a yarn feeder B 1 Wear thermoplastic elastomer yarn (a mixed bicomponent multifilament of TPU and TPEE with a diameter of 0.15mm, the mass ratio of TPU and TPEE is 1:1), a yarn feeder B 2 Wear thermoplastic elastomer yarn (a mixed bicomponent multifilament of TPU and TPEE with a diameter of 0.15mm, the mass ratio of TPU and TPEE is 1:1);

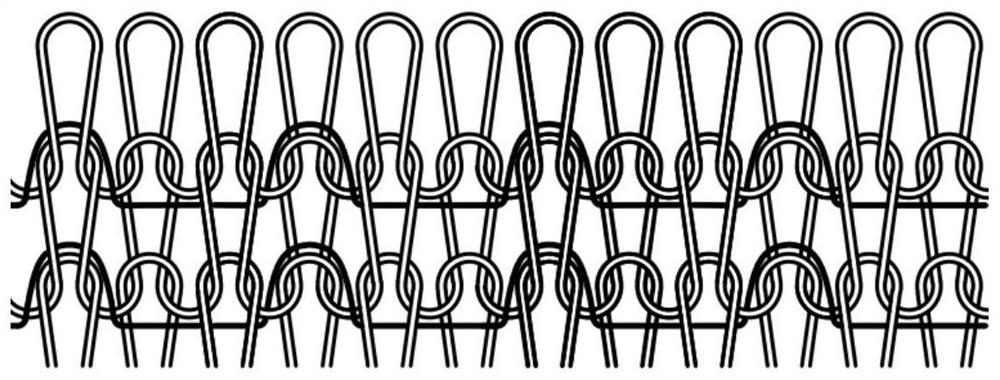

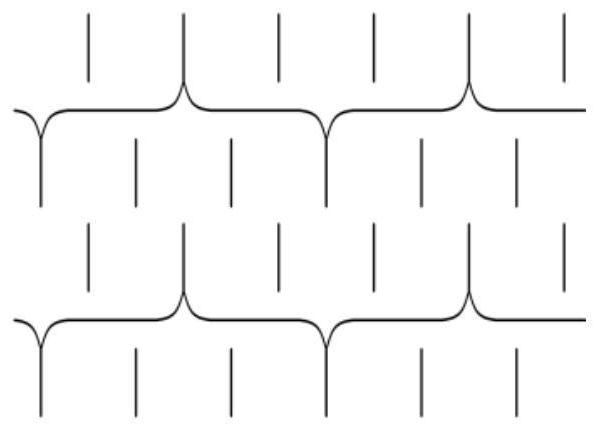

[0069] The thermoplastic elastomer yarn is introduced into the collar area by combining the rib weave and pad weave. The rib weave is 1+1 rib weave, and the pad ratio of the pad weave i...

Embodiment 2

[0081] A method for preparing a knitted collar with anti-curling characteristics, first knitting a collar with thermoplastic elastomer yarn introduced into the collar corner area, and then compressing and heat-setting the collar as a whole to obtain anti-curling characteristics knitted collar;

[0082] Three yarn feeders are used for weaving, and one yarn feeder A wears the main yarn (4 yarns 40 S cotton yarn), a yarn feeder B 1 Wear thermoplastic elastomer yarn (1 TPV wire with a diameter of 0.18mm), a yarn feeder B 2 Wear thermoplastic elastomer yarn (1 TPV wire with a diameter of 0.18mm);

[0083]The thermoplastic elastomer yarn is introduced into the collar area by combining the rib weave and the weft weft weave. The rib weave is 1+1 rib weave, and the weft weft weave is as image 3 As shown, the weaving pattern of the weft-inserted weave is as follows Figure 4 As shown, the specific weaving process is as follows (as Figure 10 shown):

[0084] First, knit one row w...

Embodiment 3

[0095] A method for preparing a knitted collar with anti-curling characteristics, first knitting a collar with thermoplastic elastomer yarn introduced into the collar corner area, and then compressing and heat-setting the collar as a whole to obtain anti-curling characteristics knitted collar;

[0096] Four yarn feeders are used for weaving, one yarn feeder A wears the main yarn (40D / 75D spandex nylon covering yarn, nylon is used as the outer covering yarn, spandex is used as the core yarn), and one yarn feeder A wears the main yarn (4 40 S cotton yarn), a yarn feeder B 1 Wear thermoplastic elastomer yarn (1 TPU wire with a diameter of 0.13mm), a yarn feeder B 2 Wear thermoplastic elastomer yarn (1 TPU wire with a diameter of 0.13mm);

[0097] The thermoplastic elastomer yarn is introduced into the collar area by combining rib weave and plating weave, the rib weave is 1+1 rib weave, the plating weave is two-line plating weave, and the plating weave is as Figure 5 As shown,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Bending stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com