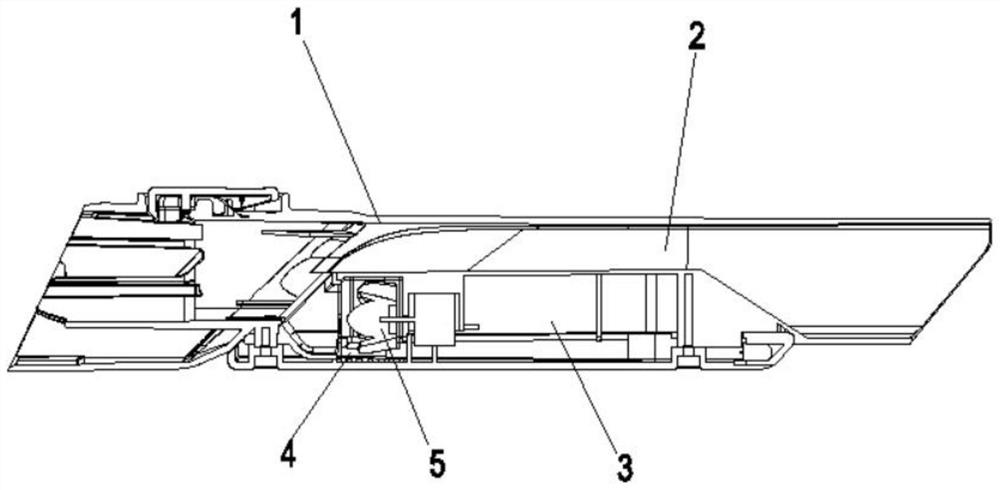

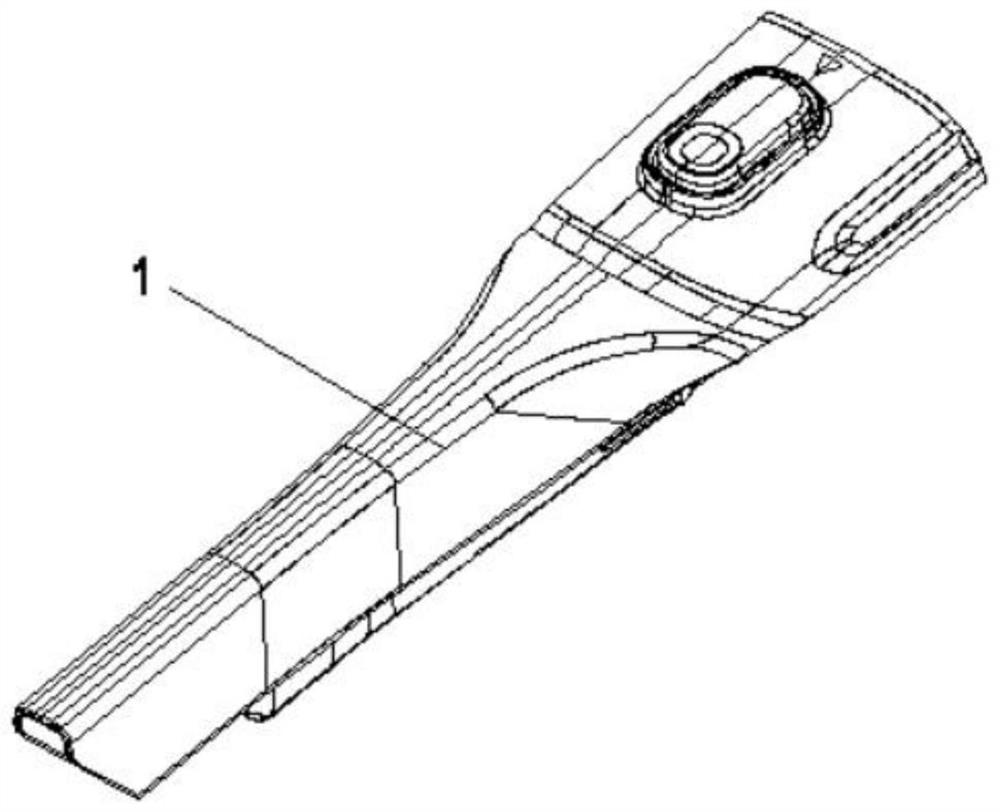

Negative-pressure-driven self-powered lighting dust collector floor brush and working method thereof

A vacuum cleaner, self-powered technology, applied in the installation of vacuum cleaners, electrical equipment, cleaning equipment, etc., can solve the problems of large occupied area, unsuitable for small and micro vacuum cleaners, high failure risk, and achieve the effect of reducing the total occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A working method for negative pressure-driven self-powered lighting vacuum cleaner floor brush, comprising the following steps:

[0028] (1) Start the vacuum cleaner, and a negative pressure is formed inside the vacuum cleaner;

[0029] (2) The negative pressure inside the vacuum cleaner and the external atmospheric pressure form a pressure difference, thereby causing the airflow to flow, and when the negative pressure reaches -0.3kpa, the negative pressure wind blade power generation wheel set 5 starts to rotate to generate electricity;

[0030] (3) The obtained electric energy is sent to the LED lamp beads, and the LED lamp beads emit light to meet the lighting requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com