Pit cover plate

A cover plate and pit technology, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of laborious operation, opening the cover plate, etc., and achieve the effect of safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

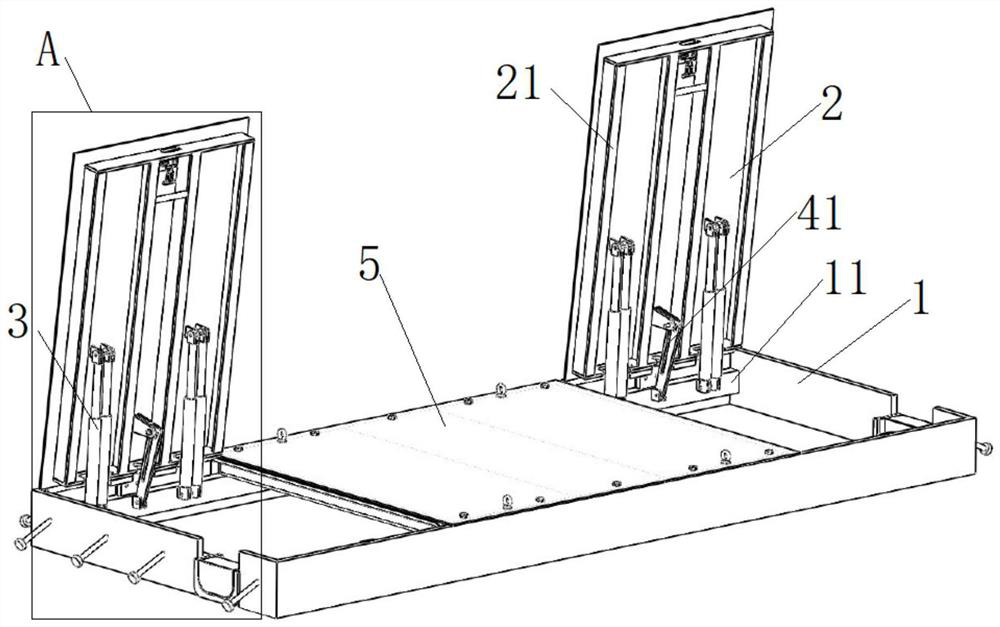

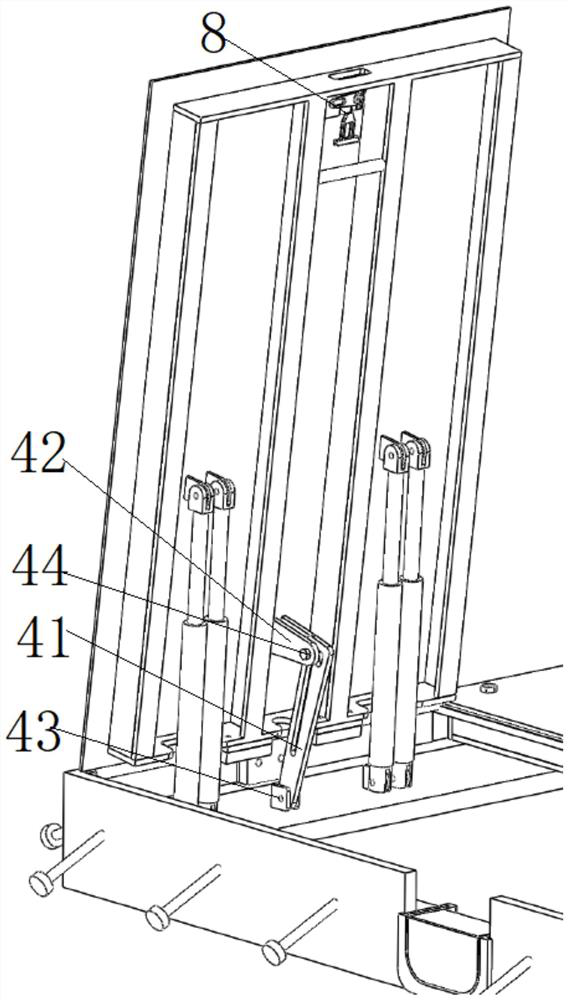

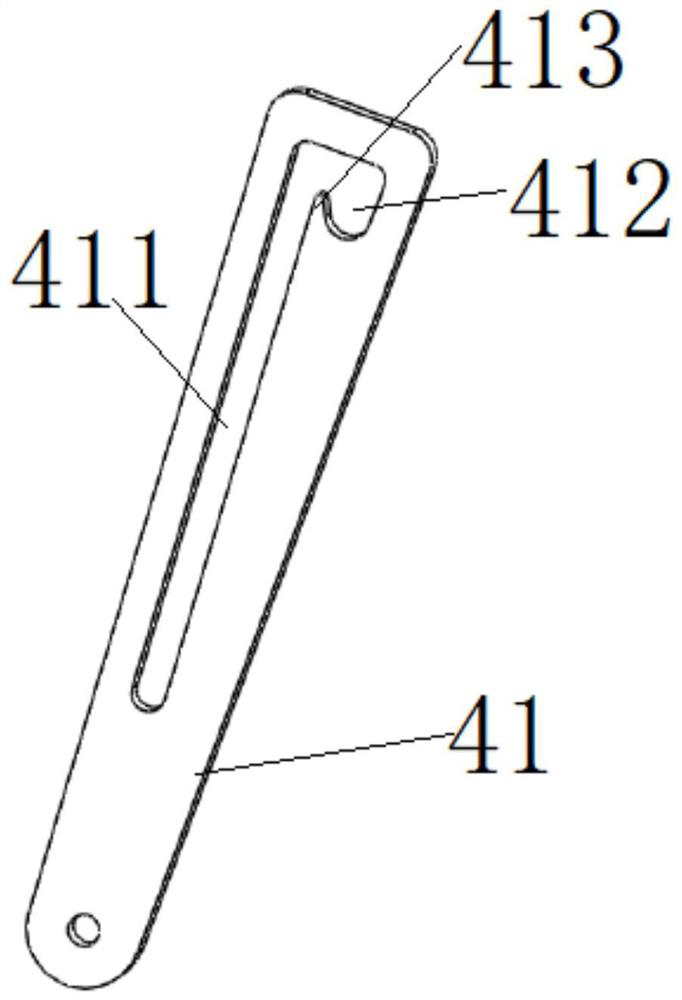

[0033] This embodiment provides a pit cover, such as Figure 1 to Figure 6 As shown, it includes a side panel 1 , at least one flip cover panel 2 and at least one support mechanism 3 . Wherein, the reversible cover plate 2 is reversibly arranged on one side of the side plate 1; The driving end of the support mechanism 3 protrudes to prop up the flip cover 2 .

[0034] The pit cover is fixed on the top of the pit. When personnel need to enter the pit to maintain electrical equipment and need to open the flip cover 2, start the support mechanism 3, so that the driving end of the support mechanism 3 protrudes outward to prop up the flip cover 2. After the flip cover 2 is detached from the side plate 1 to a certain height, the flip cover 2 can be lifted with the help of human hands, which saves time and effort and is safe to operate.

[0035] see figure 1 and figure 2 , the side plate 1 is in the shape of a rectangular frame, the pit cover includes a fixed cover 5 and two ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com