Concrete pump truck arm support, concrete pump truck arm support assembly and concrete pump truck

A concrete pump truck and jib technology, which is applied in the fields of construction, building structure, and building materials processing, etc., can solve the problems of poor passability of the whole soil pump truck, and achieve the effect of improving the passing capacity of the whole truck and being simple and convenient to drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

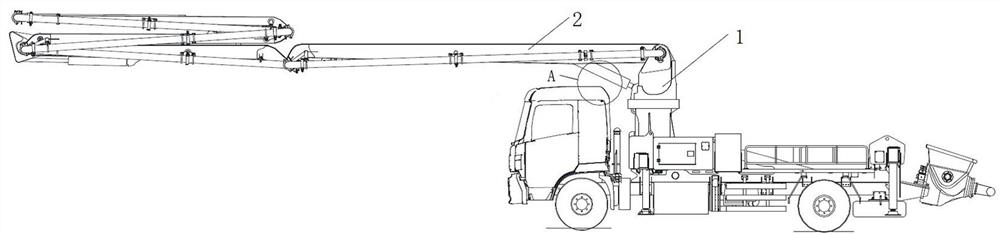

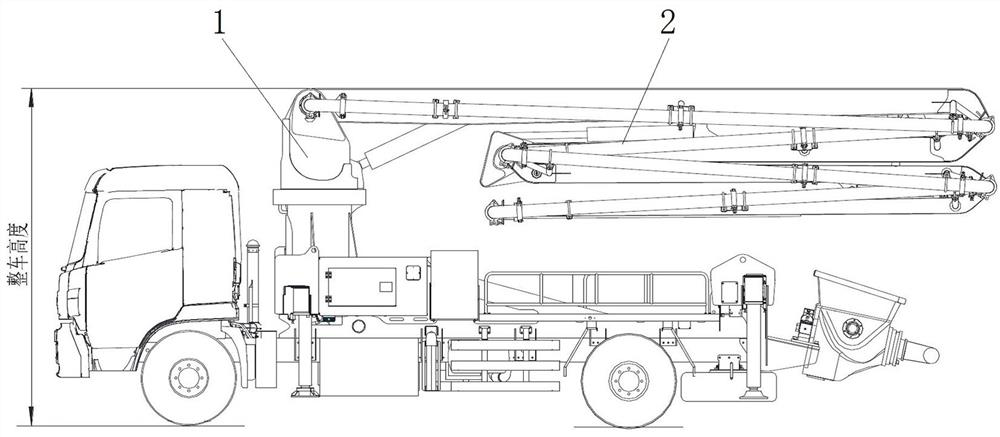

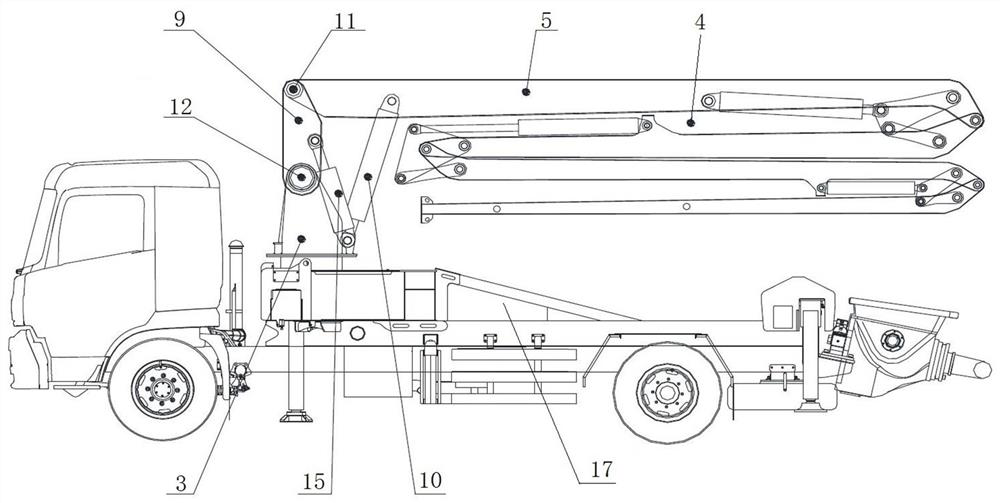

[0044] Embodiment 1 of concrete pump truck among the present invention, as image 3 As shown, the concrete pump truck includes a car body 17, a turntable 3 and a boom 4 installed on the car body 17, wherein the turntable 3 and the boom 4 form a concrete pump truck boom assembly, and the boom 4 is installed on the turntable 3, The rotation of the turntable 3 drives the boom 4 to rotate to different directions for construction work.

[0045] Specifically, such as Figure 4 As shown, the boom 4 includes a first boom section 5, a second boom section 6, a third boom section 7, and a fourth boom section 8. In addition, the boom 4 also includes a first boom section 5 and a turntable 3 The supporting arm section 9 that plays a connecting role, and the pitch drive device for driving the supporting arm section 9 to pitch and swing relative to the turntable 3, and the arm section oil cylinder 10 for driving the lower part of the boom 4 to stand up.

[0046] Specifically, one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com