Self-calibrating apacitor-type liquid level gauge

A capacitive liquid level, self-calibration technology, applied in the direction of the liquid level indicator for physical variable measurement, can solve the problems of unsatisfactory measurement accuracy and long-term stability, poor stability, etc., to achieve good long-term stability, The effect of high measurement accuracy and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

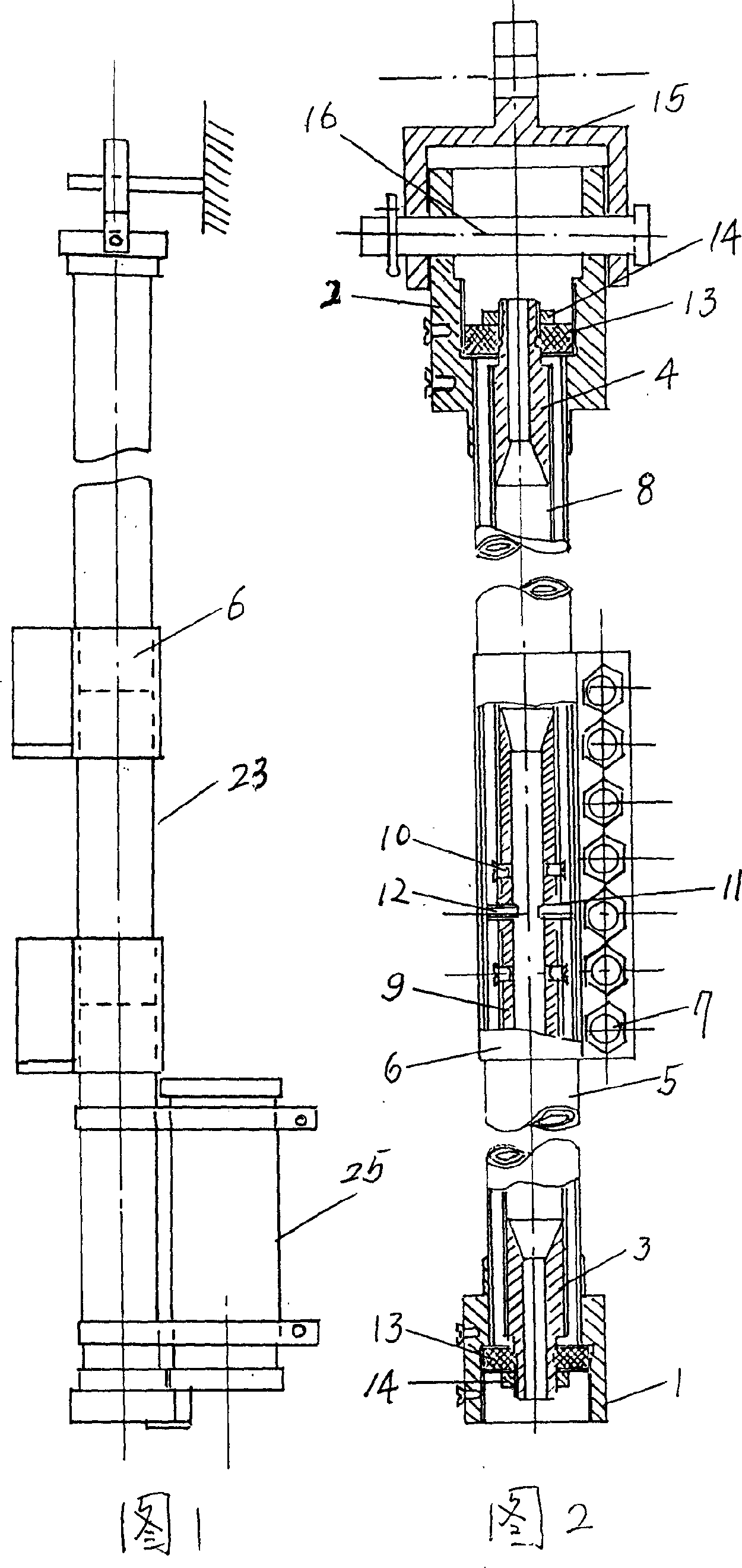

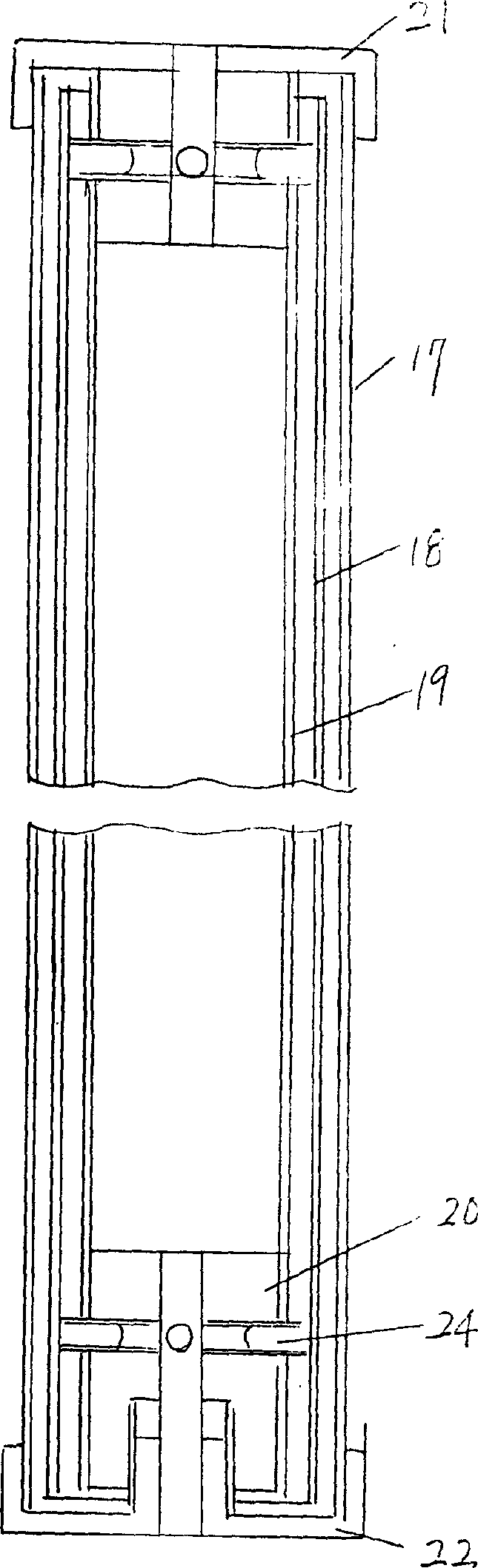

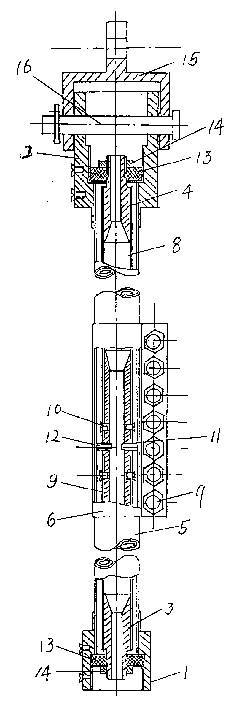

[0026] The self-calibrating capacitive liquid level gauge is a coaxial capacitive sensor composed of a calibration sensor and a measuring sensor. The measuring sensor includes an outer tube, an inner tube, a bottom joint 1 of the outer tube, a top joint 2 of the outer tube, a bottom joint 3 of the inner tube, and a top joint 4 of the inner tube.

[0027] The outer tube is made up of multi-section short outer tubes 5 butt joints, and clips 6 are sleeved at the joints of every two short outer tubes 5, and the two ends of the clips 6 are fixedly connected by clip screws 7 to clamp the joints. The upper end of the outer pipe bottom joint 1 is sleeved on the lower end of the outer pipe, and is firmly welded with the outer pipe. The lower end of the outer pipe top joint 2 is sleeved on the upper end of the outer pipe, and is firmly welded with the outer pipe.

[0028] The inner tube is composed of multiple short inner tubes 8 connected, and at the joint of every two short inner tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com