Quick closing mechanism of isolating switch and isolating switch

A kind of isolation switch, fast technology, applied in electrical switches, air switch parts, high-voltage air circuit breakers and other directions, can solve the problems of poor contact stability, slow closing instantaneous speed, etc., to achieve stable contact, strong closing force, fast The effect of closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

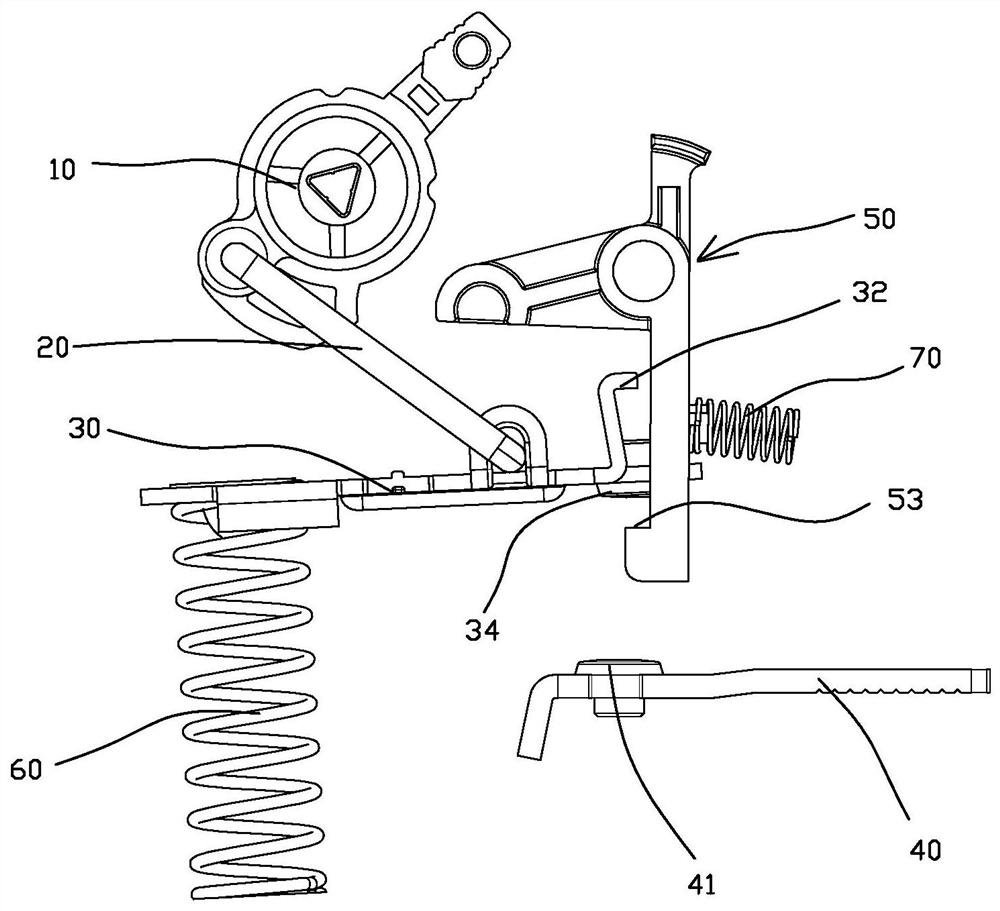

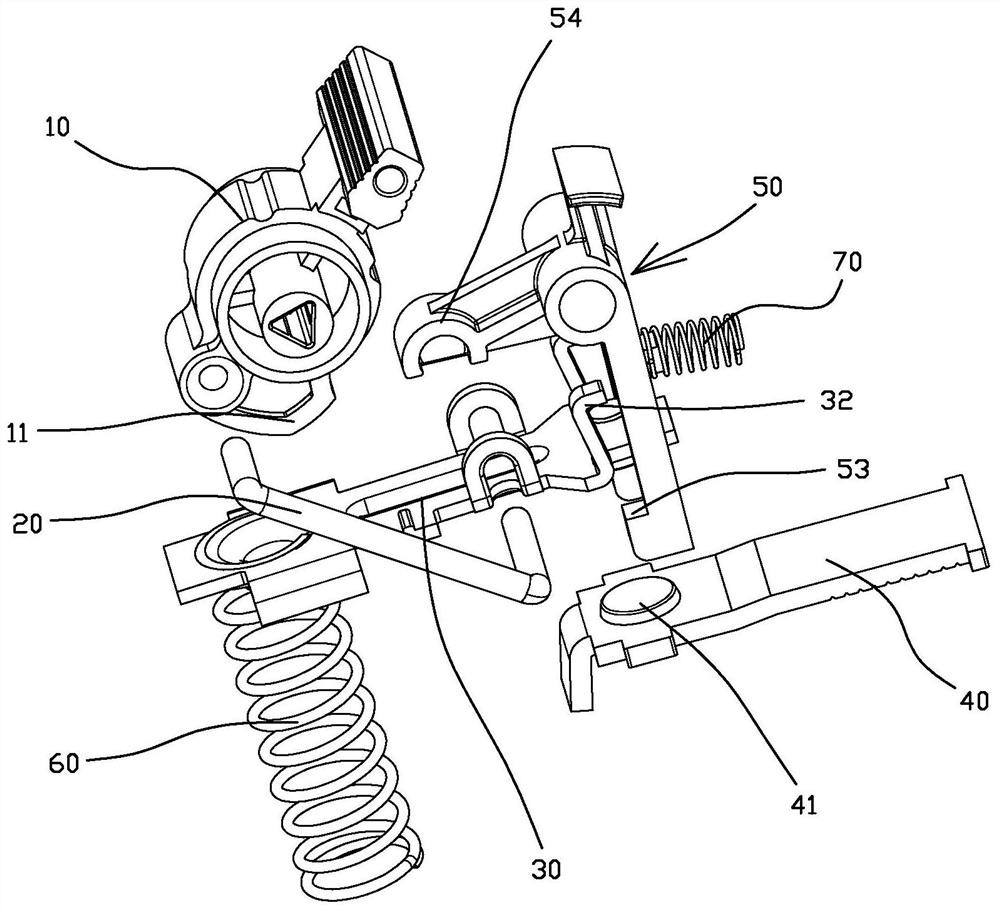

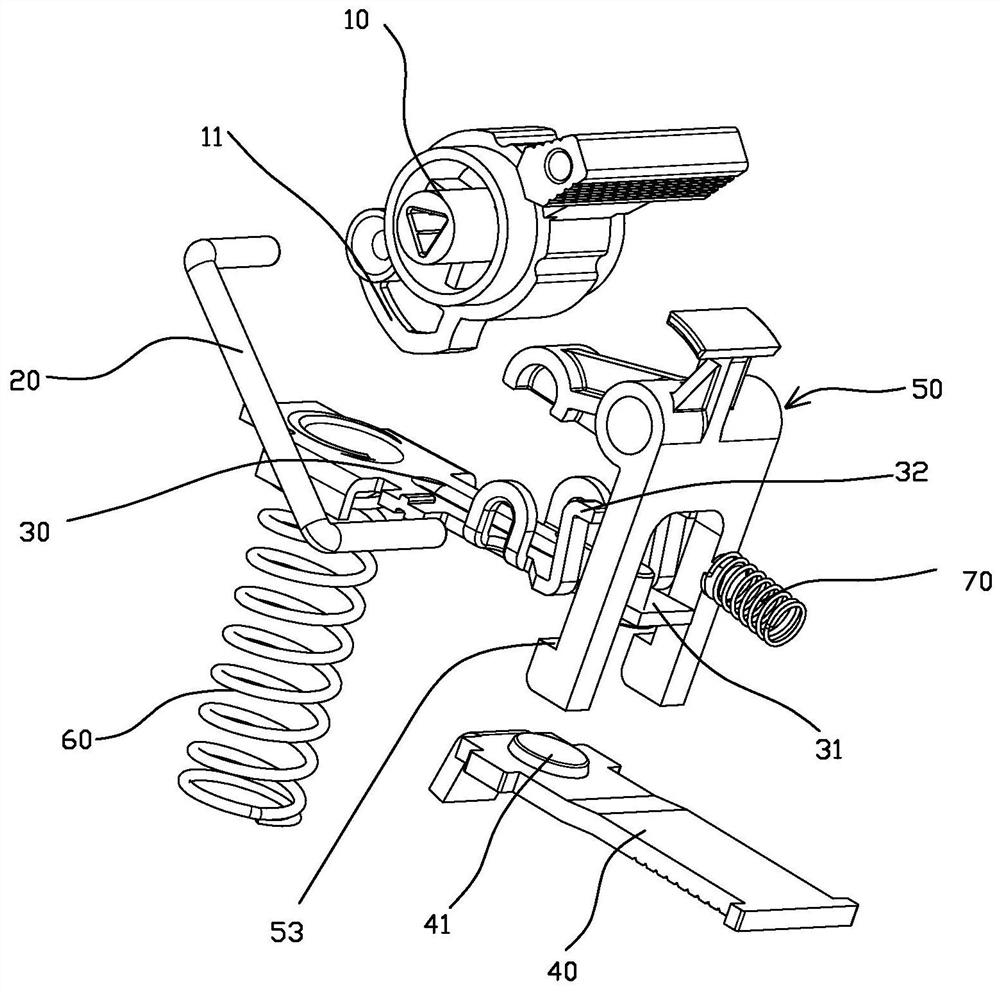

[0043] refer to Figure 1 to Figure 9 As shown, a quick closing mechanism of a disconnector provided in this embodiment includes a moving contact bracket 30 with a moving contact 34, a static contact bracket 40 with a static contact 41, an operating handle 10, a connecting Rod 20, chute, elastic driving member 60 and quick-fitting member 50; specifically, the chute is directly formed in the housing of the isolating switch. Figure 1 to Figure 9 not shown, please refer to the attached Figure 10 The chute 80 formed in the first housing 1001.

[0044]The fast closure 50 is hingedly arranged and extends to form a limited step 53. The movable contact 34 is arranged on the first end 301 of the movable contact bracket 30, and the first end 301 of the movable contact bracket 30 is further extended by Corresponding to the hook portion 32 of the limit step 53, the elastic driving member 60 acts on the second end 302 of the moving contact bracket 30, one end of the connecting rod 20 i...

Embodiment 2

[0064] The quick closing mechanism of the isolating switch provided in this embodiment is roughly the same as the quick closing mechanism of the isolating switch provided in the first embodiment, the difference lies in the orientation and implementation of the cooperation between the limit step 53 and the hook part 32 Example 1 is opposite, and the driving limit step 53 is opposite to the swinging direction of the hook portion 32 . Specifically referring to the accompanying drawings, in this embodiment, specifically, as Figure 17 As shown, the hook portion 32 is toward the second end 302 of the moving contact bracket 30, that is, as Figure 18 As shown, when assembled on the isolating switch, the hook portion 32 is set towards the left, while the limit step 53 of the quick closure 50 is set towards the right to match the hook portion 32, when the second stage is switched to the third stage ,Such as Figure 18 , 19 As shown, the driving convex part 11 of the operating handl...

Embodiment 3

[0067] The quick closing mechanism of the isolating switch provided in this embodiment is roughly the same as the quick closing mechanism of the isolating switch provided in the first embodiment, except that in the third stage, the limit step of the quick closing member 50 53 swings away from the moving contact bracket 30 to get away from the hook part 32 in different ways, refer to Figure 20 , 21 As shown, in this specific embodiment, the limit step 53 is inclined at the first stage, and when the second stage is switched to the third stage, the hook portion 32 is under the transmission pressure of the connecting rod 20 (ie, the operation The pull of the handle 10 forms a relative slide with the limit step 53 under the action of the transmission pressure applied by the connecting rod 20 , and then drives the limit step 53 of the quick closure 50 to swing away from the contact bracket 30 to give way. In this way, by realizing automatic detachment after reaching a certain pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com