Modified epoxy resin composite coating for building exterior walls, and preparation process thereof

A technology for epoxy resin and building exterior walls, applied in epoxy resin coatings, coatings, etc., can solve the problems of reduction and reduction of thermal insulation performance, and achieve the effect of high hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The specific preparation process of hydrophobic porous energy storage ore microspheres is as follows:

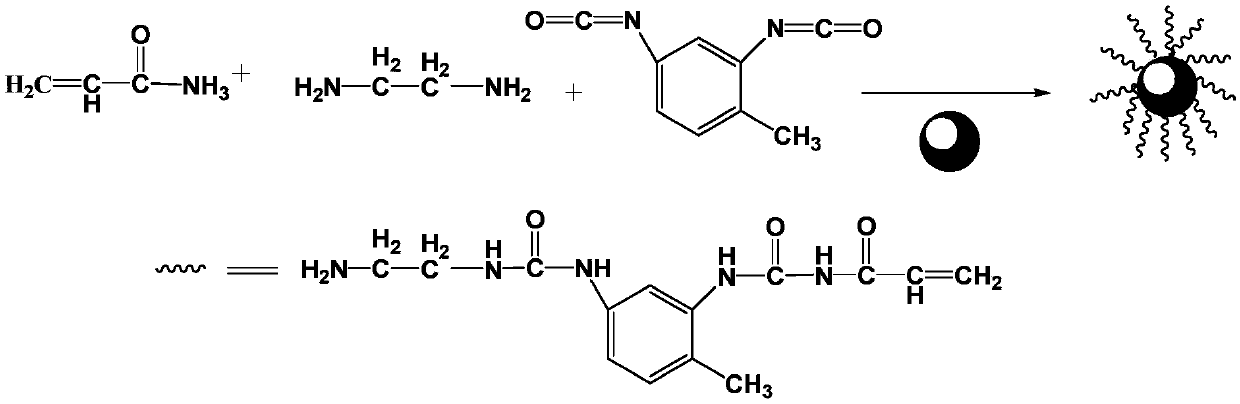

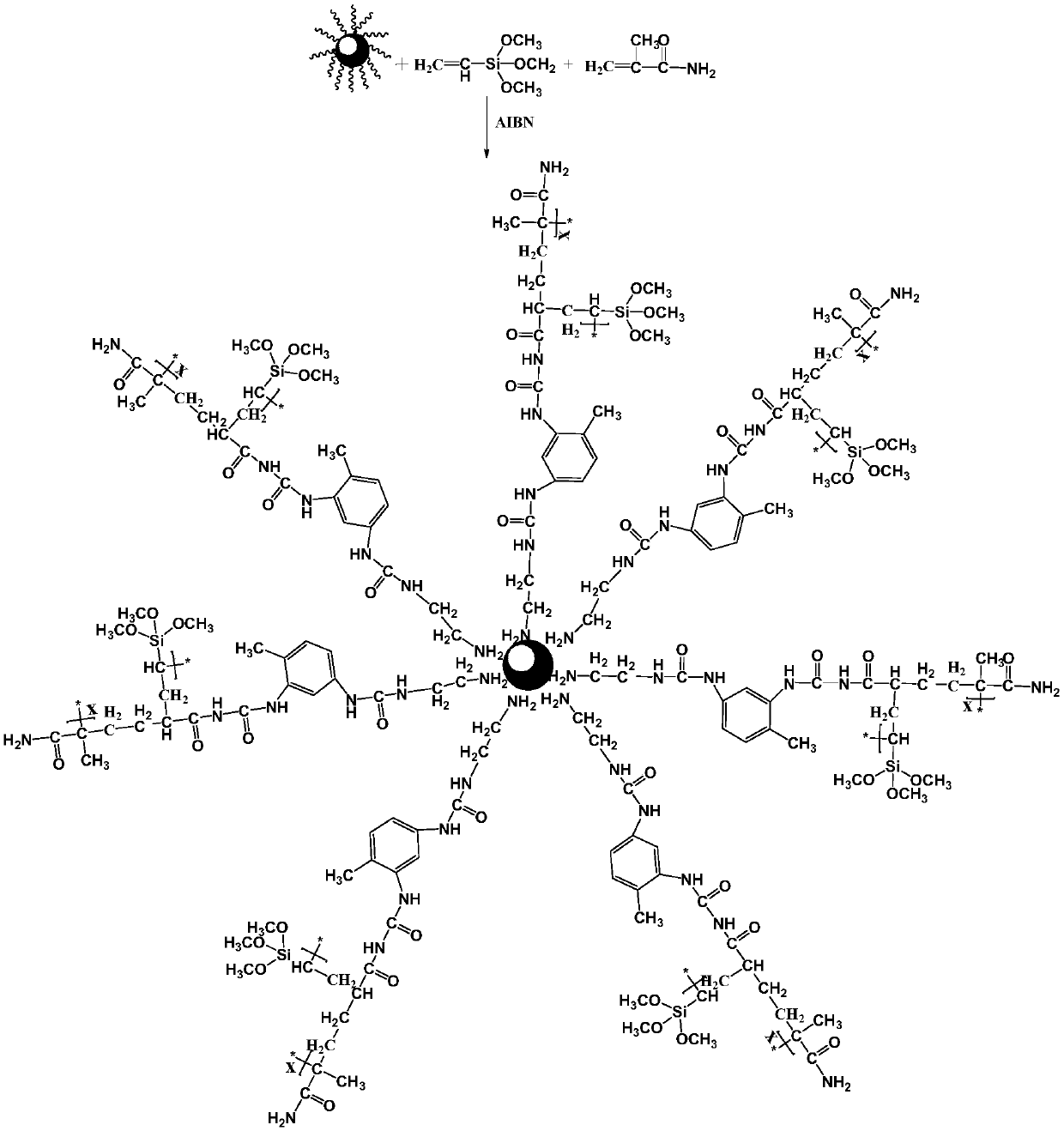

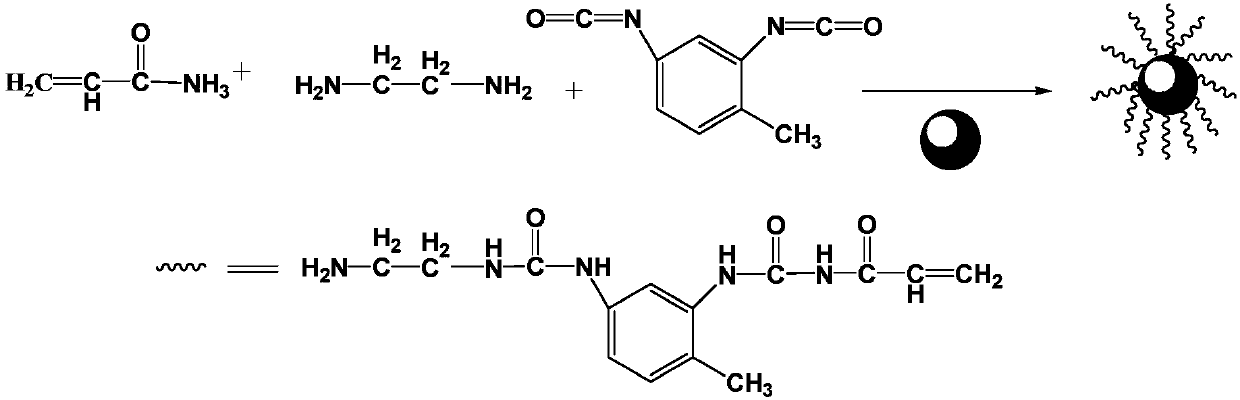

[0028] Step 1: Add 1kg of slag powder into 3.3L of water, then add 370g of ethylenediamine into it, mix well, add 34g of sodium dodecylbenzenesulfonate into it, stir and dissolve, heat up to 30-50°C, and then add Add 531g of toluene diisocyanate and 465g of acrylamide solution dropwise, keep the dropping rate at 8-10mL per minute, stir vigorously while adding dropwise, keep constant temperature reaction for 2 hours after the dropwise addition is complete, then filter and wash, and carry out in an oven at 60°C drying to obtain coated slag;

[0029] Step 2: Add 1 kg of coated slag powder prepared in step 1 into 10 L of hydrochloric acid solution with a concentration of 1 mol / L, stir and react at room temperature for 2 hours, then wash with a sodium carbonate solution with a concentration of 0.1 mol / L, and then wash with distilled water Wash with ethanol until neutral, ...

Embodiment 2

[0033] The specific preparation process of hydrophobic porous energy storage ore microspheres is as follows:

[0034] Step 1: Add 1kg of slag powder into 3.4L of water, then add 380g of ethylenediamine into it, mix well, add 37g of sodium dodecylbenzenesulfonate into it, stir and dissolve, heat up to 30-50°C, and then add Add 543g of toluene diisocyanate and 472g of acrylamide solution dropwise. The dropping rate is kept at 8-10mL per minute. Stir vigorously while dropping. drying to obtain coated slag;

[0035] Step 2: Add 1 kg of coated slag powder prepared in step 1 into 10 L of hydrochloric acid solution with a concentration of 1 mol / L, stir and react at room temperature for 2 hours, then wash with a sodium carbonate solution with a concentration of 0.1 mol / L, and then wash with distilled water Wash with ethanol until neutral, and then dry at 60°C to obtain porous ore microspheres;

[0036] Step 3: Add 900g of porous ore microspheres into 3.6L of liquid paraffin solution...

Embodiment 3

[0050] A kind of preparation technology of modified epoxy resin composite coating for building exterior wall, concrete preparation process is as follows:

[0051] In the first step, 5.5kg of bisphenol F epoxy resin is dissolved in 10kg of ethanol solution, then 2.1kg of the hydrophobic porous energy storage ore microspheres prepared in Example 1 are added thereto, and a concentration of 1.2kg is added dropwise thereto while stirring. A sodium bicarbonate solution with a concentration of 1% was stirred evenly and then heated to 50°C for 2 hours;

[0052] In the second step, add 1.2kg of hollow glass spheres, 0.8kg of titanium dioxide, 0.6kg of hydroxyl silicone oil and 0.5kg of nano-zinc oxide to the solution prepared in the first step, stir evenly and heat up to 60°C, and then dropwise add 4.7 kg formaldehyde solution, stir while adding dropwise, and react at constant temperature for 3 hours after the dropwise addition is complete;

[0053] In the third step, add 130g of disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com