Process for making a portable beverage product and a filling line therefore

A portable and beverage technology, applied in the field of beverage can manufacturing, can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

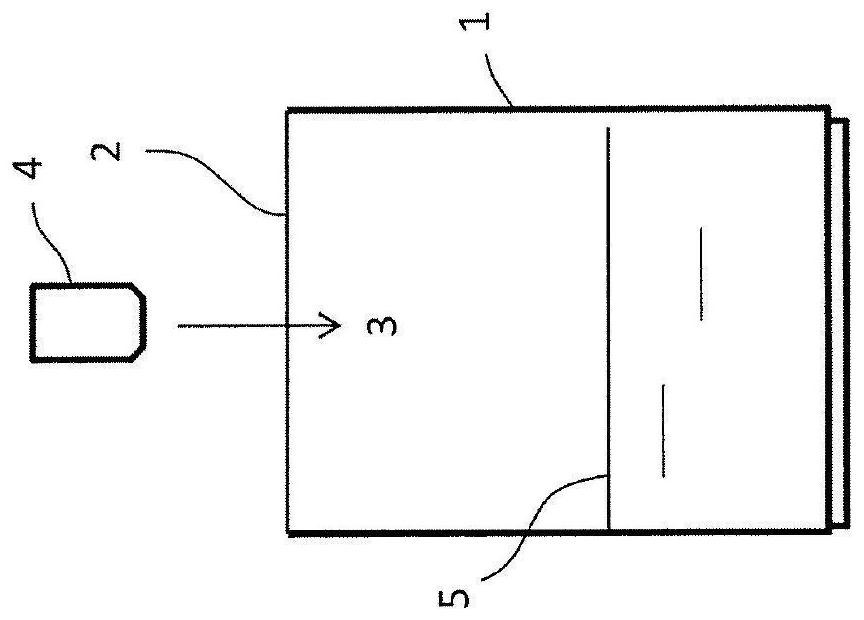

[0063] exist figure 1 In , an aluminum can 1 with a top hole 2 is filled with a first ingredient in liquid form, such as water 3 , by means of a filling head 4 . Before this filling operation, air can be removed from the tank 1 , for example by blowing in nitrogen or another inert gas.

[0064] The filling head 4 delivers a predetermined amount of liquid 3 until the liquid 3 reaches a desired level 5 in the bottom of the tank 1 .

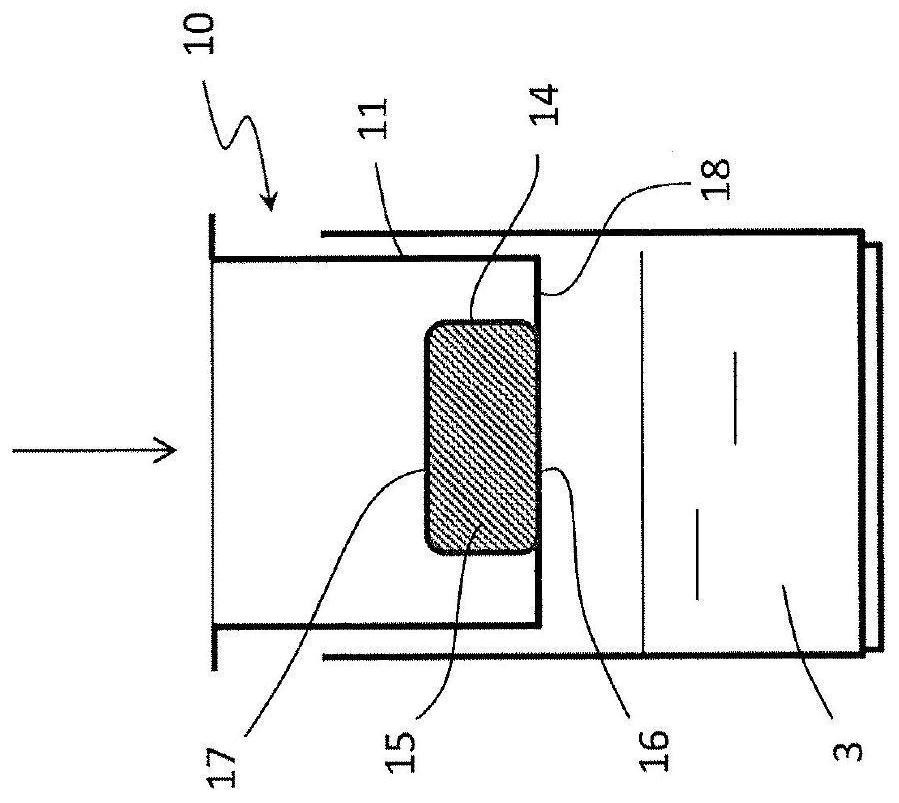

[0065] figure 2 A subsequent step is shown in which the separation device 10 is introduced into the tank 1 through the hole 2 . In this example, the separation device 10 comprises a container 11 .

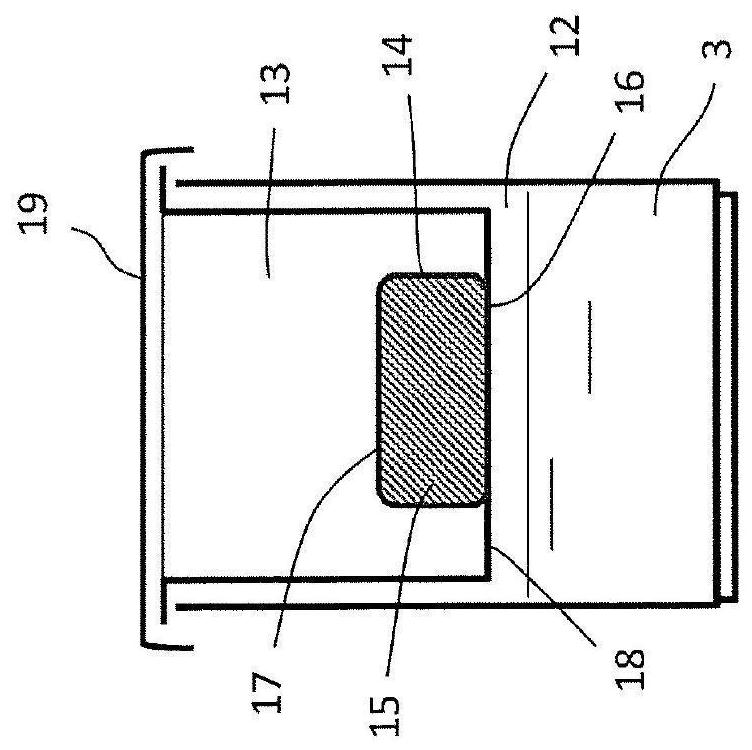

[0066] Once the separation device 10 is fully inserted into the tank 1 , the interior space of the tank 1 is divided into a first chamber 12 and a second chamber 13 .

[0067] The first chamber 12 is below the separating device 10 and contains a quantity of water previously introduced by the filling head 4 .

[0068] The second chamber 13 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com