Cover assembly and liquid storing device comprising cover assembly

A cover assembly and outer cover technology, which is applied in the field of cover assembly on the brake fluid reservoir, can solve the problems of brake fluid sealing performance influence, inseparable liquid returning to the reservoir, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

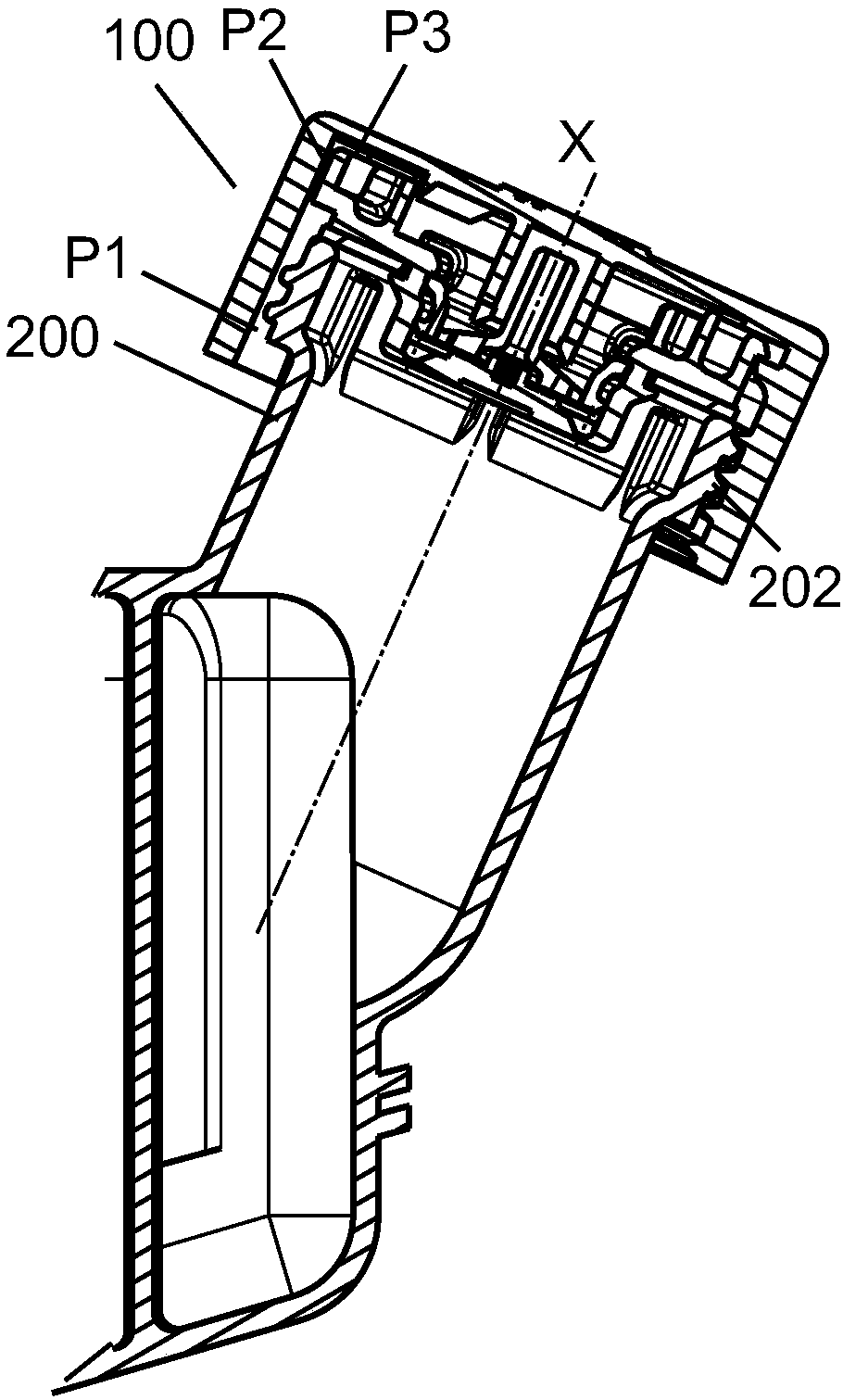

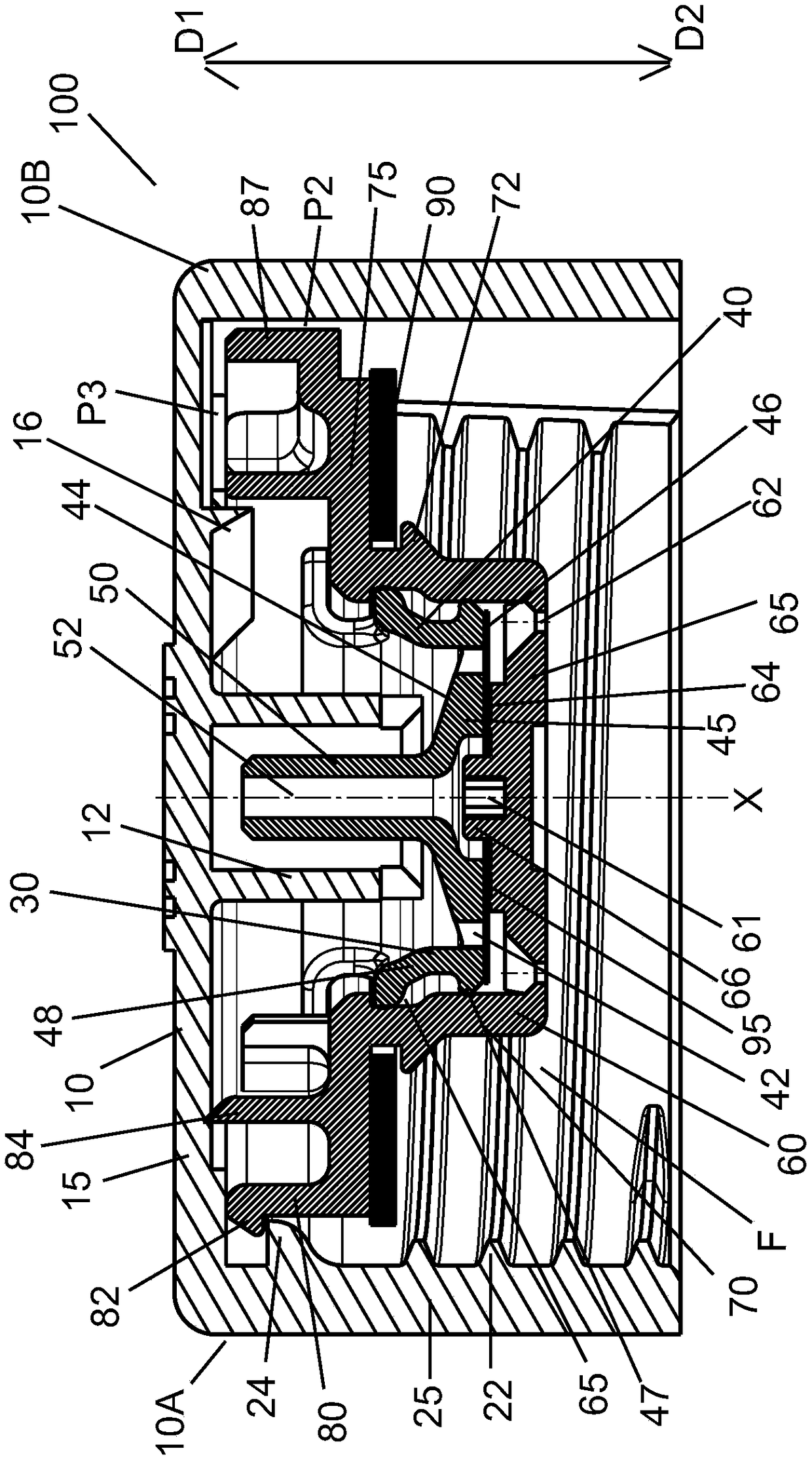

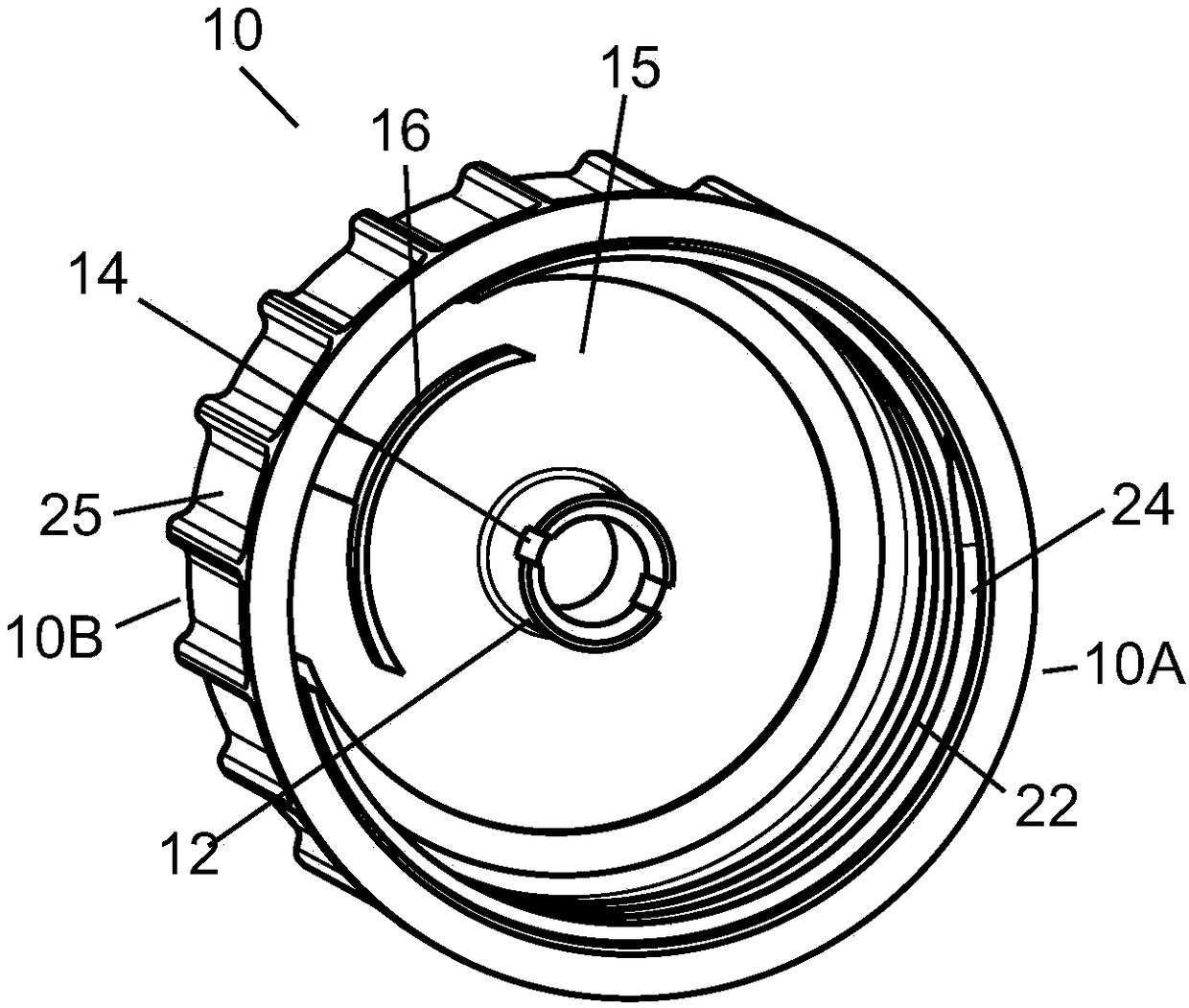

[0022] The cap assembly according to the invention is primarily intended to fit and fluidly seal to a brake fluid reservoir of a vehicle. In particular, the present cap assembly is fitted to and fluidly sealed to an inlet tubular fitting (hereinafter "tubing") of a brake fluid reservoir. However, those skilled in the art should understand that the cap assembly of the present invention is not only applicable to the brake fluid reservoir of a vehicle, but is applicable to any similar reservoir with the same functional requirements.

[0023] Firstly, the cap assembly of the present invention, when used with the reservoir, ie engaged with the tubing of the reservoir, provides a dedicated air intake passage separate, or at least partially separate, from the exhaust passage. Specifically, the cap assembly of the present invention provides a common intake and exhaust passage that allows the air in the reservoir to be discharged to the outside air and allows the outside air to enter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com