Directional toppling auxiliary device for forestry cedar felling

A technology for dumping auxiliary devices and fir trees, which can be used in forestry, agriculture, applications, etc., and can solve problems such as trees jamming saw blades, labor consumption, and motor damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

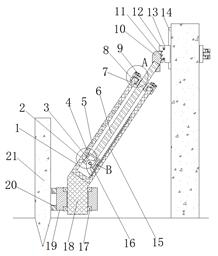

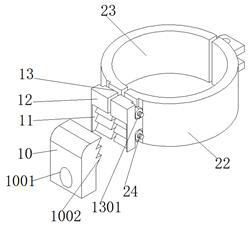

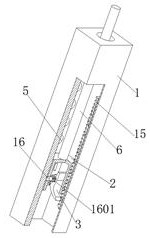

[0029] refer to Figure 1-5 , a forestry fir tree felling directional dumping auxiliary device, including a wooden stake 21 nailed near the root of the side of the tree to be felled to avoid falling, a mother bucket 1 with an upward opening and a rectangular parallelepiped structure, and two hinged hoops One 22 and clamp two 23, one end of clamp one 22 and two clamps 23 away from the hinge point are reserved with projections 12, and the side of the two projections 12 far away from the trunk is provided with top tooth grooves 11 near the middle The upper surface and the lower surface of the two projections 12 are provided with notches 13 coaxially distributed, and fastening bolts 24 are fixed between the gaps 13 between the two projections 12, and the outer wall of the stake 21 is close to the bottom. A bearing holder 19 is provided at the end, and the upper and lower surfaces of the bearing holder 19 are respectively clamped with mutually symmetrical tapered roller bearings 17...

Embodiment 2

[0038] refer to figure 1 and Figure 5 , a forestry fir felling directional dumping auxiliary device. Compared with Embodiment 1, this embodiment also includes two insertion rings 901 that are symmetrical to each other at the top of the inner threaded pipe 7 near the edge, and the two insertion rings 901 are Insertion rods 9 are inserted into the rings 901 .

[0039] Wherein, the opposite ends of the two insertion rods 9 are hinged with a folding rod 8, so that when the inner threaded pipe 7 needs to be rotated during use, if the resistance is too large, only the folding rod 8 needs to be straightened, thereby increasing the power arm. The length makes the rotation more labor-saving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com