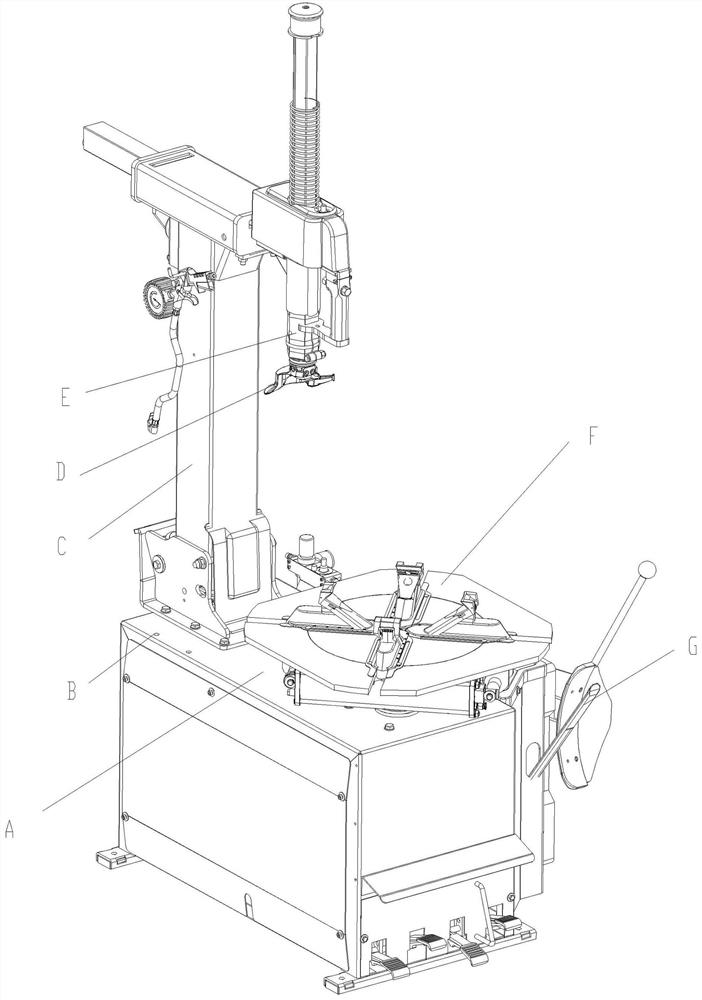

New tire dismounting device

A tire and mounting seat technology, applied in tire installation, tire measurement, tire parts and other directions, can solve the problems of not being able to completely replace, easy to scratch tires, and small tire hook force to remove tire hooks, shortening the length and increasing the rigidity. , Increase the effect of horizontal rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

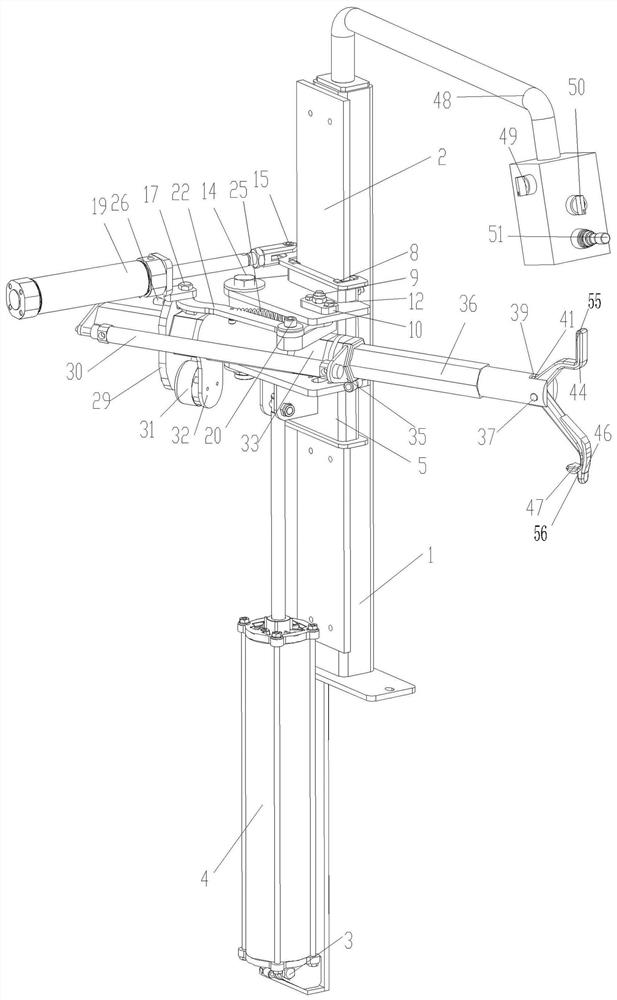

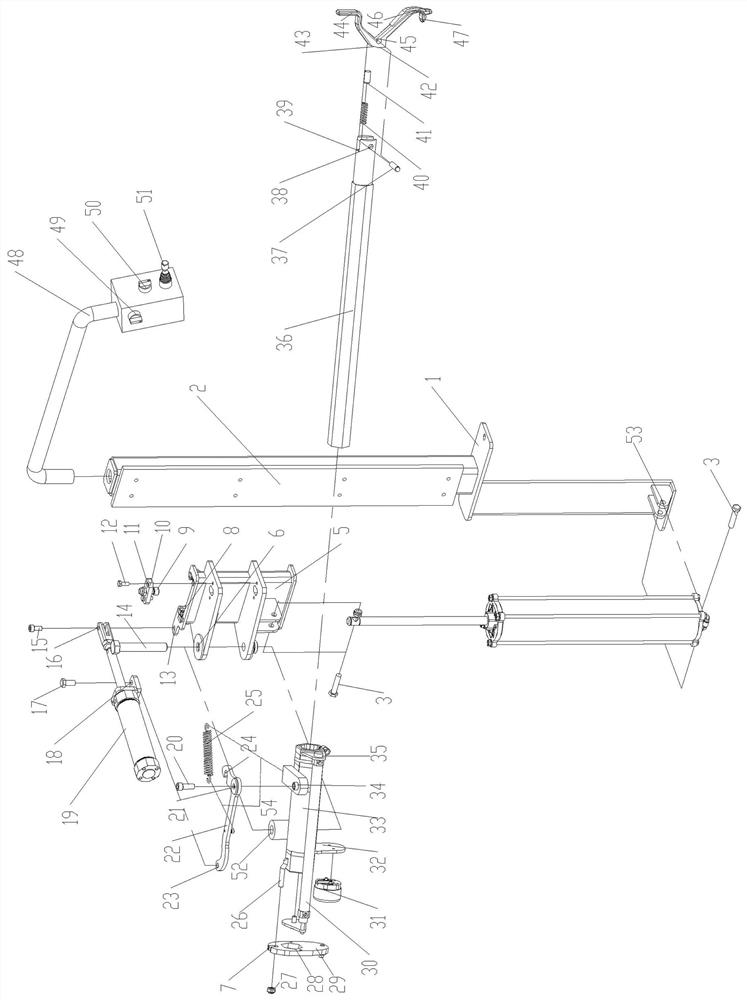

[0040] As shown in the figure, the present invention includes a fixed bracket 1, the upper part of the fixed bracket 1 is provided with a vertical guide rail 2, the lower end of the fixed bracket 1 is hinged to the lower end of the vertical first executive cylinder body, and the vertical guide rail 2 is provided with a sliding support 5, the second The lower end of the hinged sliding support 5 at the power output end of the upper end of the executive cylinder;

[0041] One side of the sliding support 5 is hinged with the rear portion of the horizontal support frame 33, and the horizontal support frame 33 is equipped with a working arm 36, a second actuator cylinder for driving the axial locking of the working arm 36, and a fourth cylinder for driving the axial movement of the working arm 36. Execution cylinder;

[0042] The middle part of the lock hook 22 is hinged on the horizontal support frame 33 , one end of the lock hook 22 is hinged to the main body of the third actuator...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap