Rotor, motor, rotor locking method and transportation tool

A technology of rotor and rotor shaft, applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of non-repeatable disassembly, low fault tolerance, and increase of rotor shaft length, etc. , to achieve the effect of safe and reliable locking method, simple locking method and reducing process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

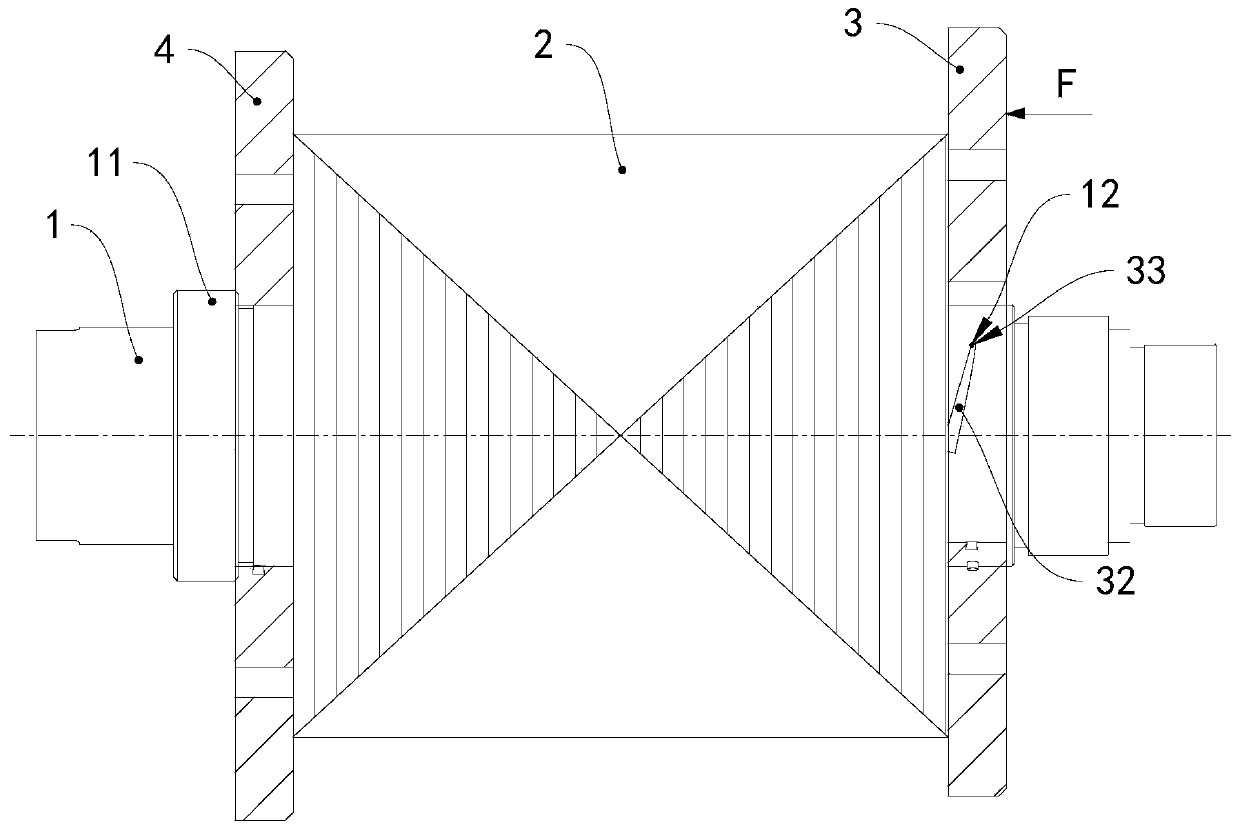

[0041] see figure 1 , the rotor of this embodiment includes a rotor shaft 1 , a rotor core 2 , a baffle 4 , a baffle 3 and a connecting assembly 10 . The rotor core 2, the baffle 3 and the baffle 4 are all sleeved on the rotor shaft 1, and the rotor core 2 is located between the baffle 3 and the baffle 4, and the baffle 4 and the rotor core 2 are on the rotor shaft 1. It is limited axially between the shaft shoulder 11 of the rotor shaft 1 and the baffle 3 , and the baffle 4 abuts against the shaft shoulder 11 in the axial direction.

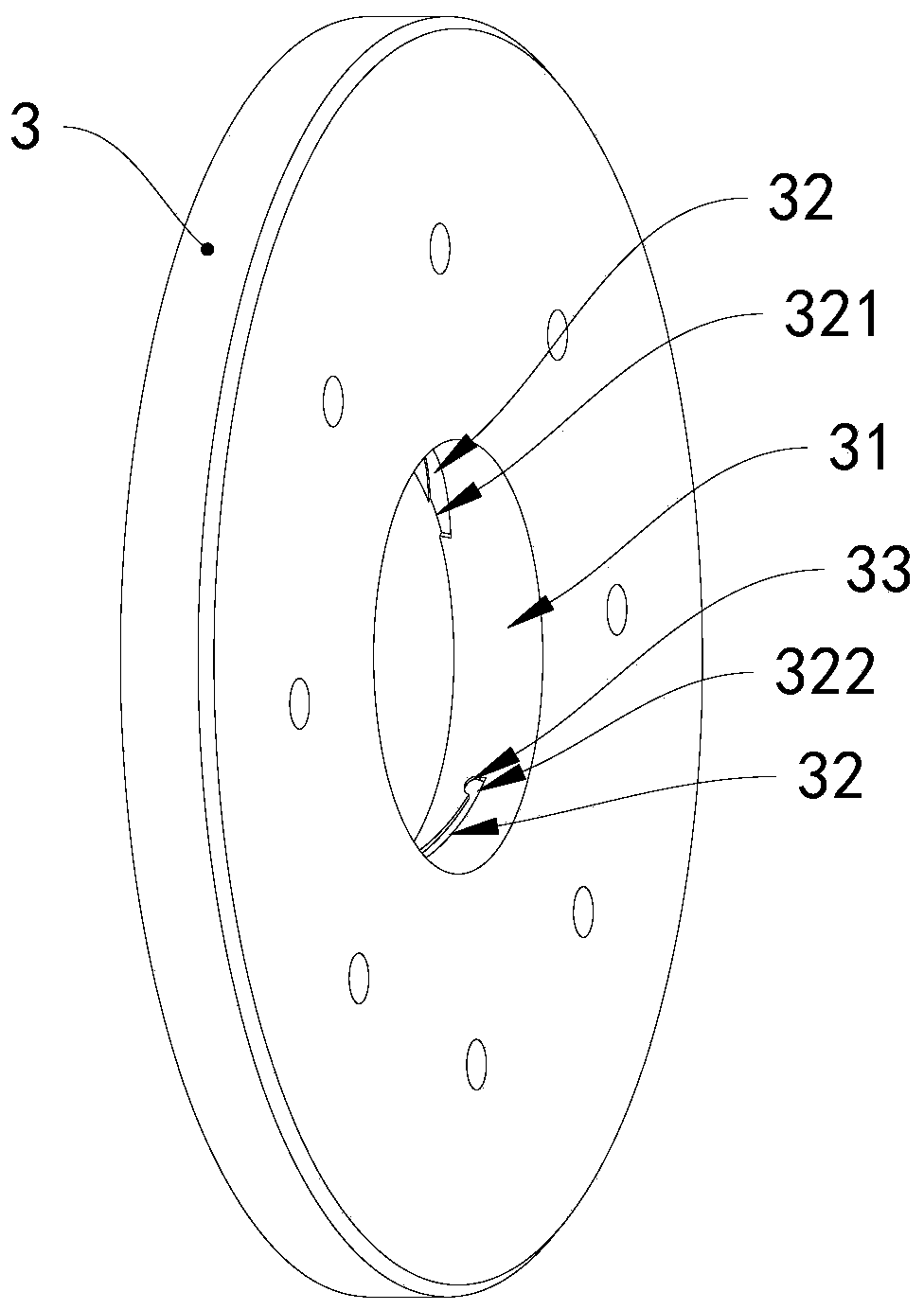

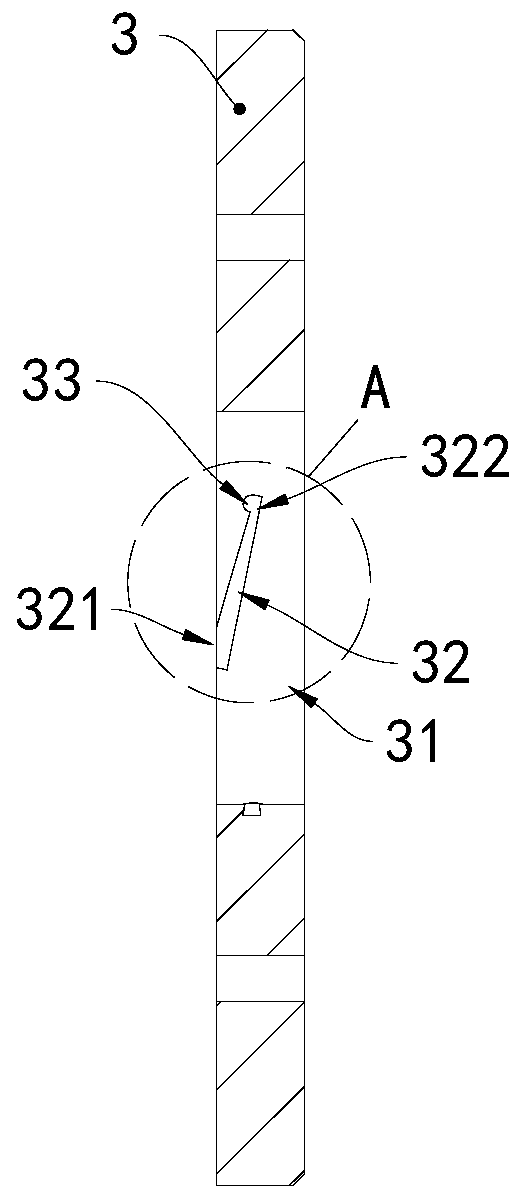

[0042] see Figure 1 to Figure 3 , the baffle plate 4 and the baffle plate 3 are both ring-shaped, and the middle part of the baffle plate 3 is provided with a circular hole 31, the circular hole 31 is in clearance fit with the rotor shaft 1, and the connecting assembly 10 is connected between the circular hole 31 and the rotor shaft 1 Between them, the connecting assembly includes an arc-shaped guiding groove 32 and a cylindrical limiting pro...

no. 4 example

[0067] As the description of the fourth embodiment of the rotor and the rotor locking method of the present invention, only the differences from the third embodiment of the above-mentioned rotor and the rotor locking method will be described below.

[0068] see Figure 13 , the limit groove 72 of this embodiment includes an axial limit portion 721 and a circumferential limit portion 722, the guide groove 71, the axial limit portion 721 and the circumferential limit portion 722 are sequentially connected, and the circumferential limit portion 722 The outlet end 723 of the axial limiting portion 721 extends along the axial direction of the rotor to a side close to the stator core.

[0069] In the steps of the rotor locking method, after the stop protrusion 70 enters the axial limit portion 721 of the limit groove 72 from the outlet 712 of the guide groove 71, the baffle plate 7 continues to be rotated, and the limit protrusion 70 is limited from the axial direction. The outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com