Energy-saving louver blade, louver and louver skylight roof

A louver blade and energy-saving technology, applied in the field of shutters, can solve problems such as energy waste, inability to achieve waterproof and heat insulation, and complex window frame structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The blinds in embodiment 1 are blinds without heat insulation function, specifically as follows:

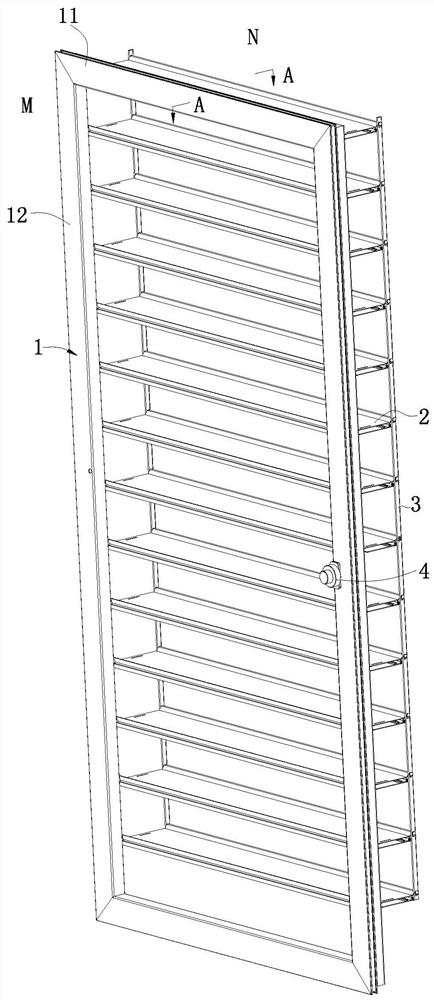

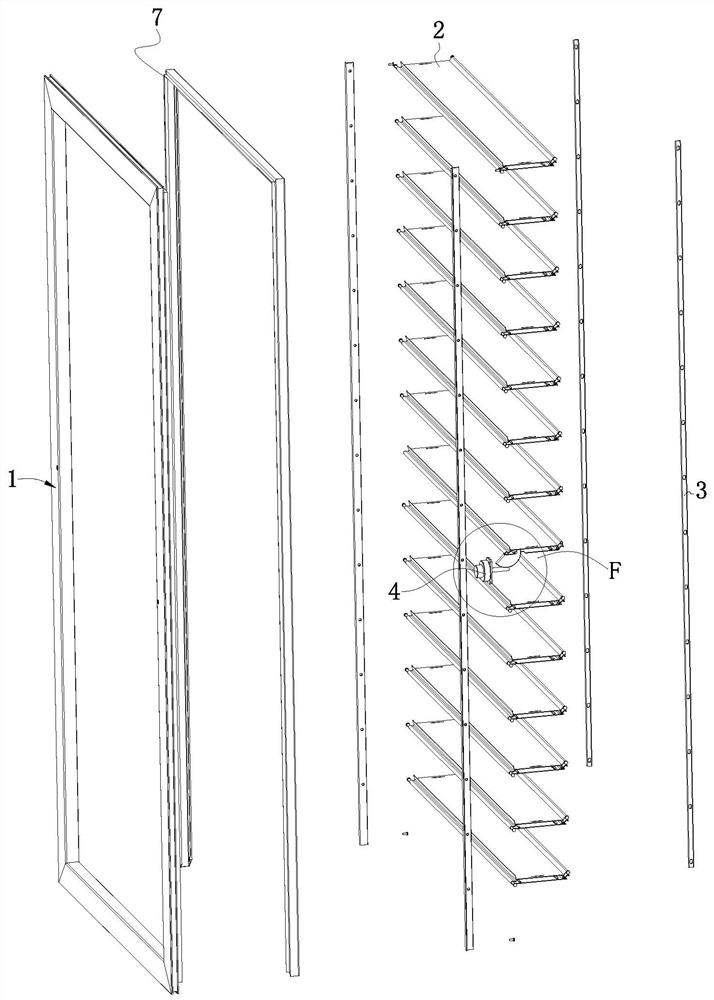

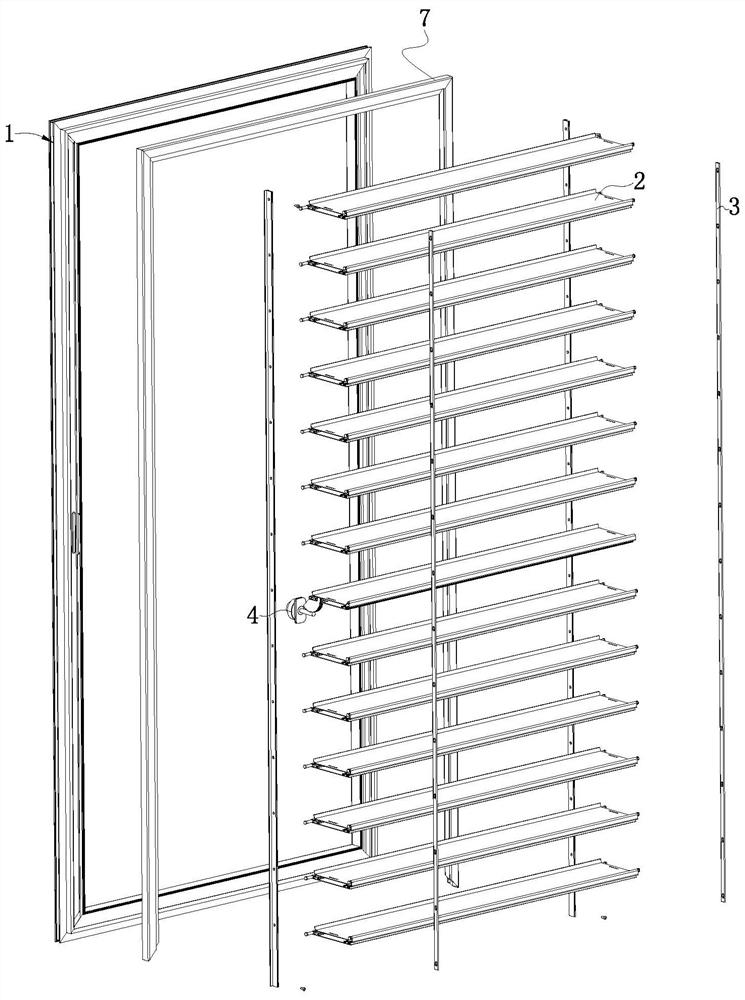

[0070] Such as Figure 1 to Figure 4 As shown, the single pendulum linkage shutter includes a frame body 1 , louver blades 2 , linkage connecting strip 3 and window opening and closing device 4 .

[0071] Such as Figure 1 to Figure 3 As shown, the frame body 1 includes a transverse keel 11 and a longitudinal keel 12. In this embodiment, there are two transverse keels 11 and two longitudinal keels 12. The two transverse keels 11 and the two longitudinal keels 12 are connected end to end to form a middle A frame structure with space.

[0072] Such as Figure 5 to Figure 7 As shown, the cross section of the transverse keel 11 includes a transverse keel body 111, at least two extensions 112 extending upward from the transverse keel body 111 and parallel to each other, a limiting portion 113 extending inward from the extensions 112, and a stopper 113 located on the transver...

Embodiment 2

[0102] This embodiment is an energy-saving louver. The difference between Embodiment 2 and Embodiment 1 lies in the specific structure of the louver blades and the fact that the frame is provided with heat insulating materials on the indoor side, specifically:

[0103] Such as Figure 32-34 As shown, the louver 2 includes a blade body 21, the length of the blade body 21 is greater than the distance between the inner sides of the two keel bodies 121, the blade body 21 is provided with a swing axis end 216 and an outer swing end 217, and the swing axis end 216 is located on the blade body One end of 21, the outer swing end 217 is positioned at the other end of blade body 21, is provided with pin shaft accommodating hole 22 at swing axis end 216, the outer wall of swing axis end 216 is circular, the outer wall of swing axis end 216 and The shaft centers of the pin shaft accommodation holes 22 are coaxial, and the outer swing end of the blade body 21 is provided with ribs 23 protr...

Embodiment 3

[0113] Such as Figure 21 to Figure 23 As shown, a linkage louver skylight roof includes roof beams 100 , roof longitudinal beams 200 , louver blades 2 , linkage connecting strips 3 and window opening and closing devices 4 .

[0114] The roof beam 100 includes an upper roof beam 101 and a lower roof beam 102 . A roof stringer 200 is connected between the roof upper beam 101 and the roof lower beam 102, and more than two roof stringers are provided. In this embodiment, the roof has a gable shape.

[0115] The roof beams are I-beams. Such as Figure 22 As shown, the roof stringer 200 includes the roof stringer body 201 and the longitudinal keel 12 .

[0116] Such as Figure 24 and Figure 25 As shown, there are upwardly extending positioning and fixing plates 2011 on both sides of the roof stringer body 201, a placement groove 2012 is formed between the positioning and fixing plates 2011, and spacers 2013 extending in the longitudinal direction are arranged in the placemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com