Construction method of bell and spigot concrete pipe

A technology of concrete pipes and construction methods, which is applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve problems such as high working pressure, affecting construction quality, and slow construction progress, so as to reduce damage, Save manpower and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1. This embodiment provides a construction method for a socket concrete pipe, which is characterized in that it includes the following steps:

[0050] (1) Lay a concrete cushion with a specified design thickness in the excavated pipe trench, then vibrate and level it with a flat plate, measure the center line, and reserve the settlement;

[0051] (2) Place the socket concrete pipe to be installed in the pipe trench, so that the distance between the socket of the socket concrete pipe to be installed and the socket of the installed socket concrete pipe is kept at 50mm-100mm, It should be noted here that the appearance inspection should be carried out before the installation of the pipe fittings, check the appearance of the pipe fittings, the size of the sockets and sockets of the pipe fittings, and the flatness of the working surfaces of the sockets and sockets, measure and record each pipe fitting with a special measuring gauge The inner diameter of the socket...

Embodiment 2

[0056] Embodiment 2, on the basis of Embodiment 1, in step 3, when placing the concrete pipe to be installed in the excavated pipe trench, it is necessary to ensure that the axis of the concrete pipe to be installed is aligned with the installed concrete pipe. The axes are collinear. When backfilling with stone chips in step 4, it should be backfilled layer by layer along both sides of the concrete pipe and compacted layer by layer.

Embodiment 3

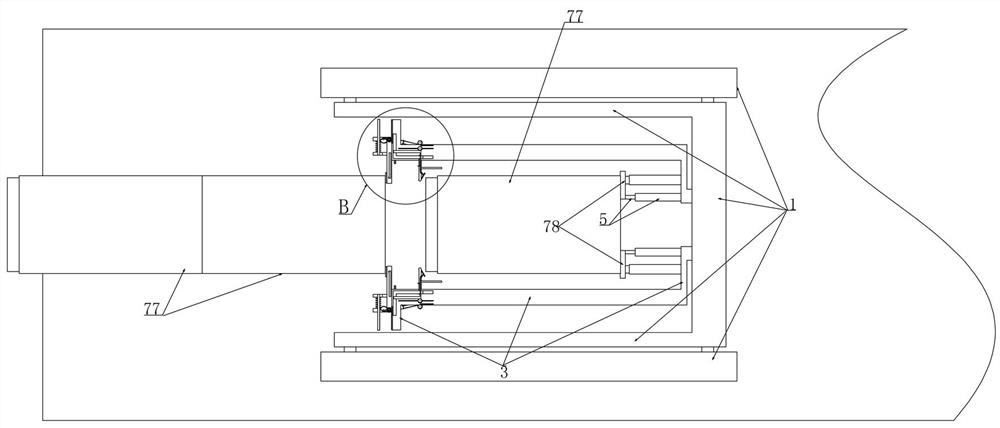

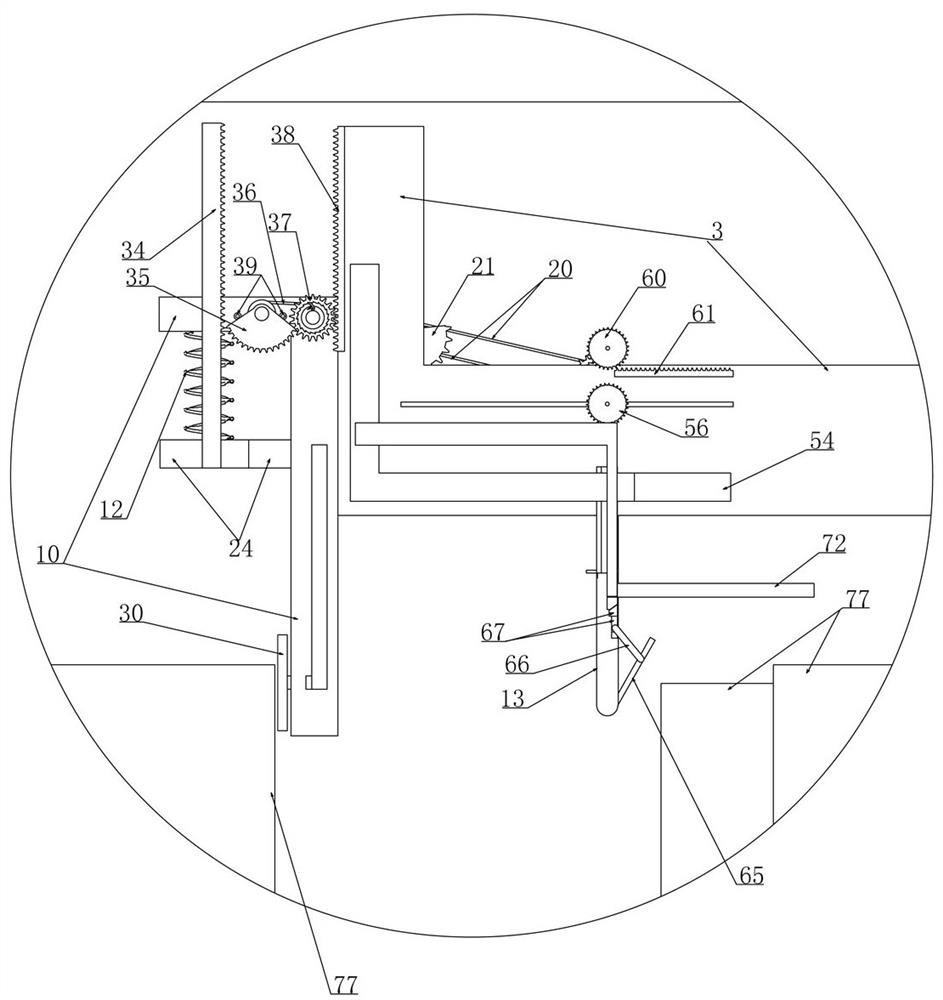

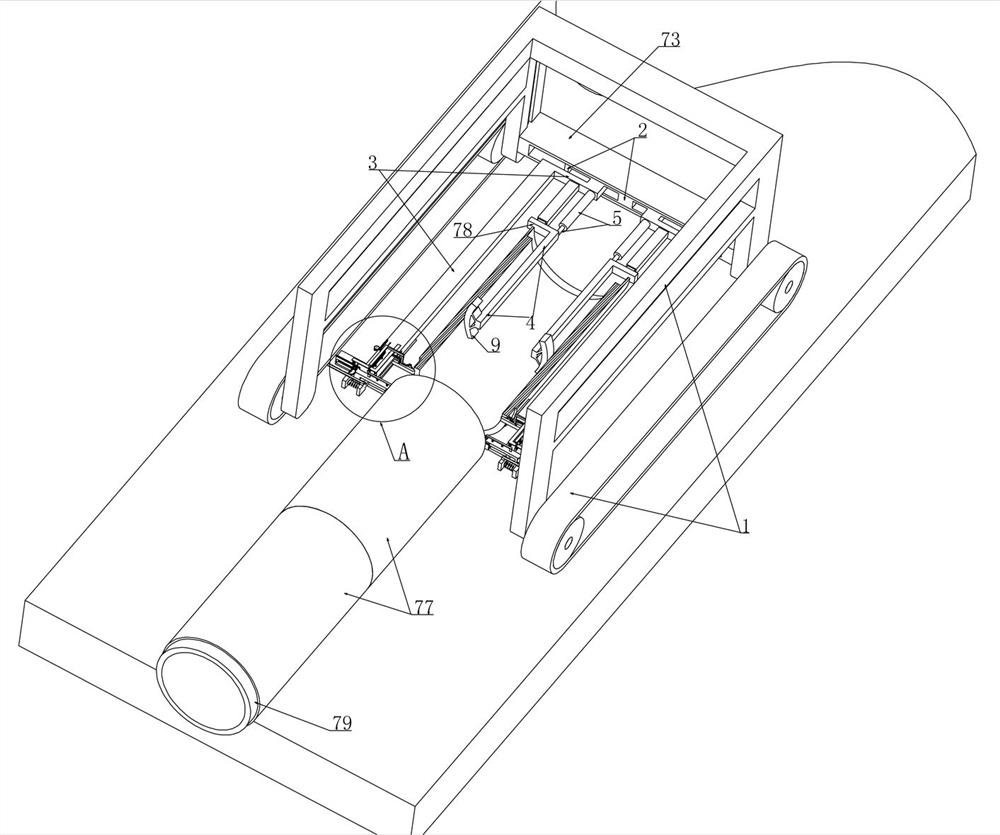

[0057] Embodiment 3, this embodiment provides a construction device for the socket concrete pipe in Embodiment 1-2, refer to the attached image 3 Shown, comprise crawler vehicle 1, it is characterized in that, with reference to attached Figure 9 As shown, we vertically slide and install an accommodation cavity 42 on the crawler vehicle 1, and one end of the accommodation cavity 42 longitudinally is screwed with a lifting screw 8 that is rotatably installed on the crawler vehicle 1, and the lifting screw 8 is driven by a lifting motor (Fig. (not shown in ) drive, we slide and install the bearing chamber 2 longitudinally in the accommodation chamber 42, and the Z-shaped rods 3 longitudinally slidably installed in the bearing chamber 2 are longitudinally spaced in the bearing chamber 2, and the two Z-shaped rods 3 are jointly connected with an expansion device And the expansion device comprises the bidirectional leading screw 6 that is rotatably installed in the bearing chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com