Positioning method for determining measurement points of acceleration sensors of head-type impact module

A technology of acceleration sensor and positioning method, which is applied in the direction of impact test, measuring device, machine/structural component test, etc. It can solve the problems of uncertain force direction, small size, and large test result, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

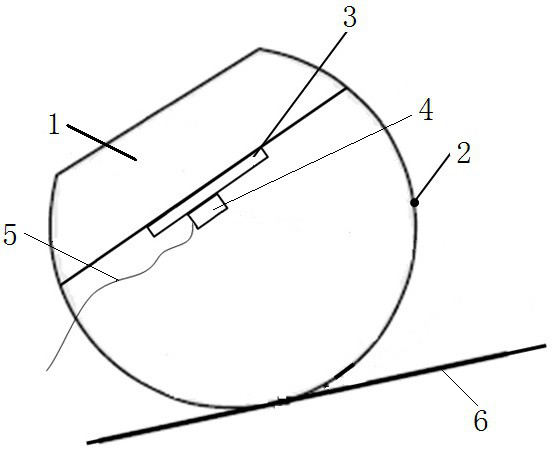

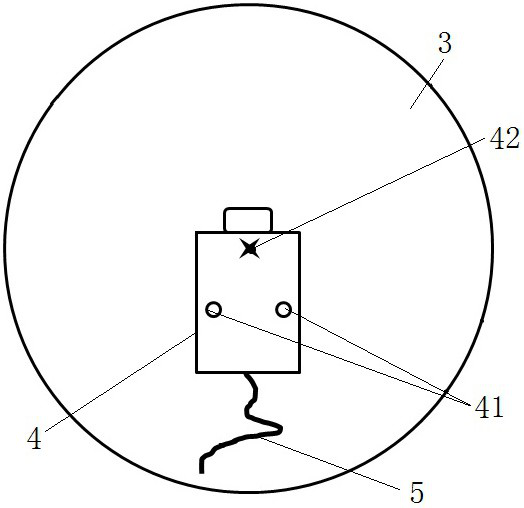

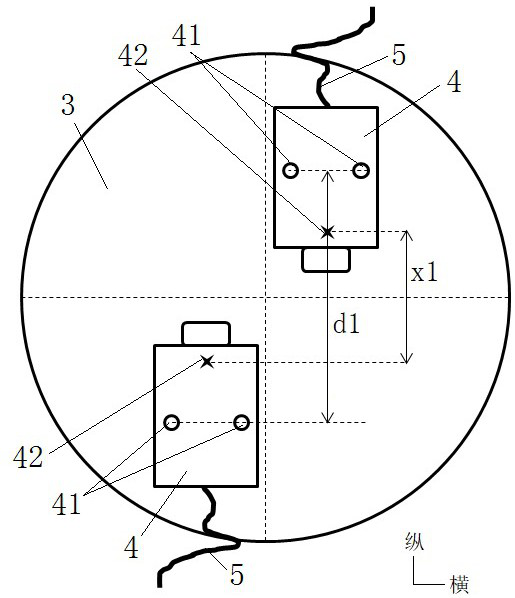

[0024] see figure 1 , the head-shaped impact module shown includes a cover plate 1 and a hemispherical head-shaped model part 2, the cover plate 1 closes the opening of the head-shaped model part 2 to form a cavity, and the cover plate 1 is close to the middle of one side of the cavity Convex is provided with the installation platform 3 that is cylindrical, see figure 2 , the acceleration sensor 4 is fixed on the installation platform 3 through the installation hole 41, and the measurement point 42 of the acceleration sensor 4 is located on the center line of the installation platform 3, while ensuring that the measurement point 42 coincides with the center of the sphere of the head model part 2, it needs to be explained Yes, since the installation platform 3 is a cylinder, its center line is the line connecting the centers of the upper and lower circles. The outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com