Corrosive agent for displaying austenite grain boundary of martensitic stainless steel and display method

A technology for martensitic stainless steel and austenite grain boundaries, which is applied in the field of corrosive agents and displays for martensitic stainless steel austenite grain boundaries, and can solve the problems of low-carbon high-alloy steel without corrosive agents and unreasonable corrosion methods. Achieve the effect of high corrosion success rate, good display effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

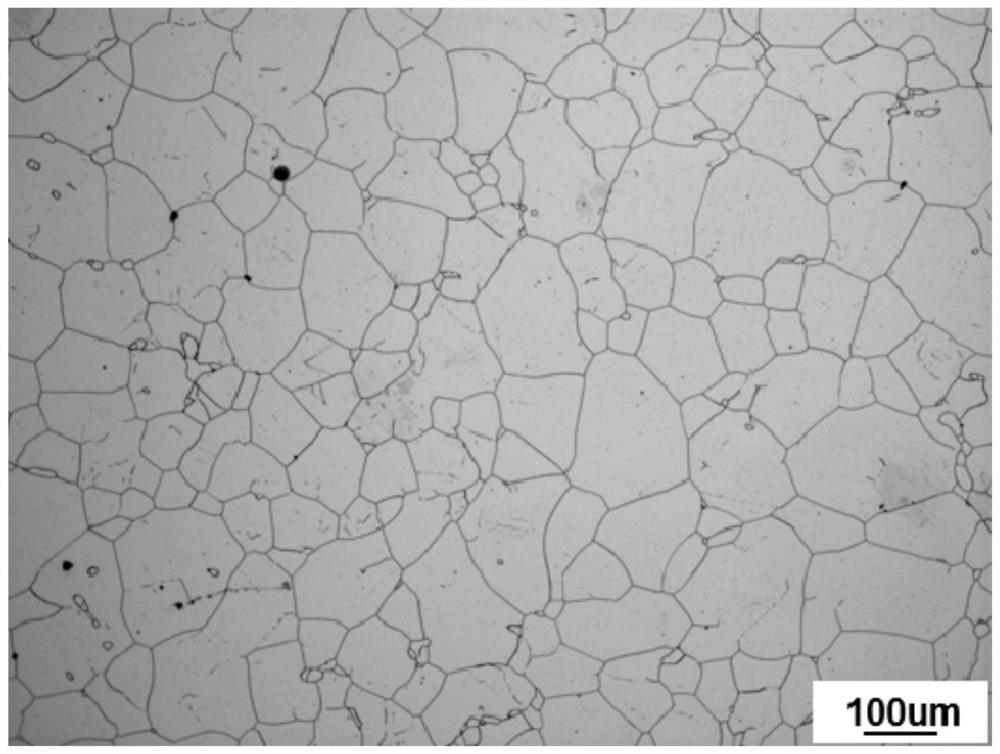

Embodiment 1

[0031] In this example, the grade of low-carbon high-alloy steel is 0Cr16Ni5Mo1, and the specific chemical composition and mass percentage are: C: 0.055%, Cr: 15.32%, Ni: 4.82%, Mo: 0.87%, Si: 0.35%, Mn : 0.88%, P: 0.005%, S: 0.002%, Sn: 0.028%, Cu: 0.04%, and the rest are Fe and unavoidable impurity elements.

[0032] ① Preparation of metallographic samples:

[0033] a. Cut a block sample of 10mm×10mm×5mm by wire cutting method, quench it after austenitizing at 1100℃ for 12 minutes, and prepare for subsequent grinding and polishing;

[0034] b. Coarse grinding of samples: Grind the samples sequentially with 180#→320#→600# silicon carbide water-resistant sandpaper. Rotate 90 degrees so that the new wear marks are vertical or nearly perpendicular to the previous wear marks, and grind until the new wear marks cover the previous wear marks. Use tap water as a lubricant when grinding ;

[0035] c. Fine grinding of the sample: Grind the coarsely ground sample on 1200# silicon ca...

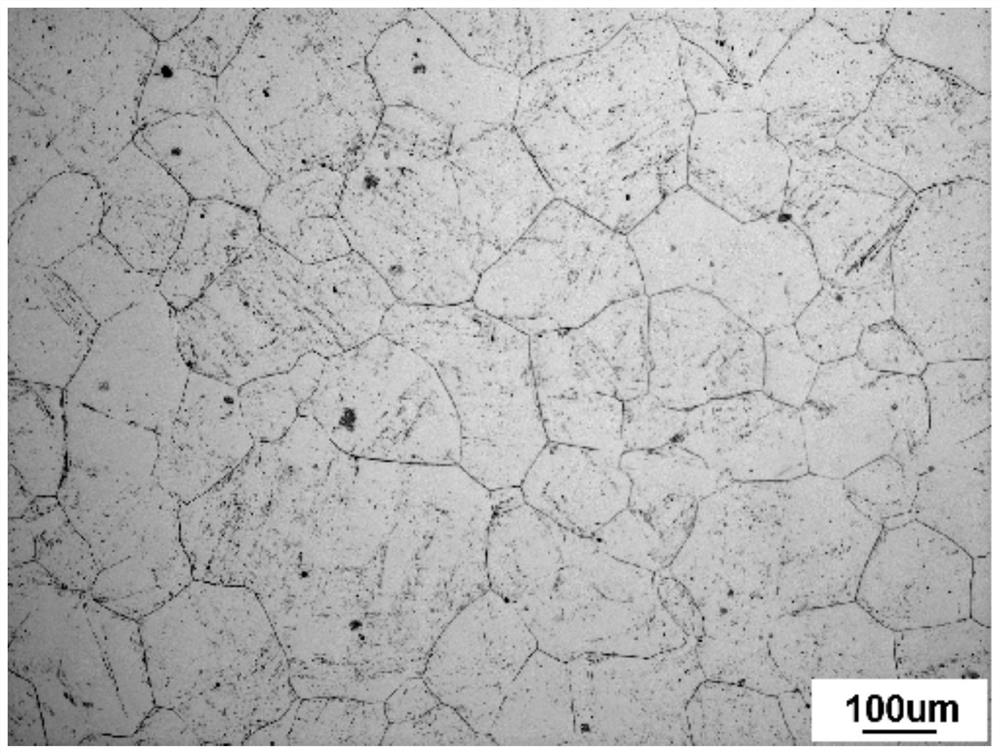

Embodiment 2

[0041] In this example, the grade of low-carbon high-alloy steel is X12CrMoWVNbN10-1-1, and the specific chemical composition and mass percentage are: C: 0.11%, Cr: 10.35%, Ni: 0.80%, Mo: 1.00%, Si: 0.08%, Mn: 0.41%, P: 0.008%, S: 0.004%, W: 1.03%, V: 0.18%, Al: 0.02%, N: 0.05%, Nb: 0.04%, the rest is Fe and unavoidable impurity elements.

[0042] ① Preparation of metallographic samples:

[0043] a. Cut a block sample of 10mm×10mm×5mm by wire cutting method, and quench it after austenitizing at 1150°C for 30 minutes to prepare for subsequent grinding and polishing;

[0044] b. Coarse grinding of samples: Grind the samples sequentially with 180#→320#→600# silicon carbide water-resistant sandpaper. Rotate 90 degrees so that the new wear marks are vertical or nearly perpendicular to the previous wear marks, and grind until the new wear marks cover the previous wear marks. Use tap water as a lubricant when grinding ;

[0045] c. Fine grinding of the sample: Grind the coarsely ...

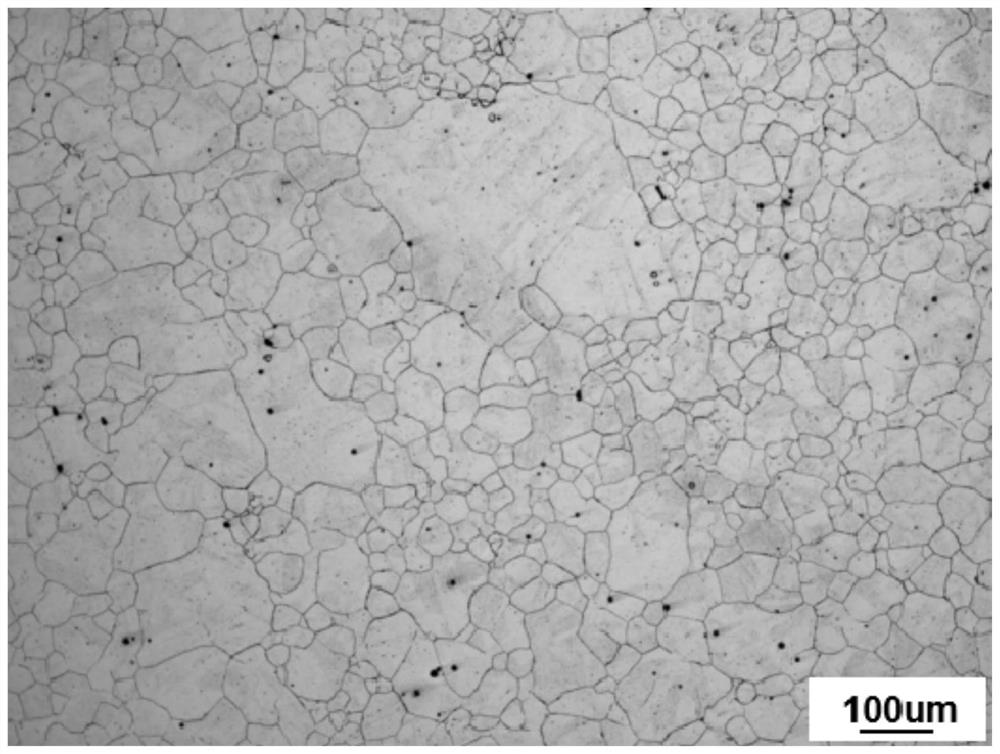

Embodiment 3

[0051] In this example, the low-carbon high-alloy steel is COST-FB2 rotor steel, the specific chemical composition and mass percentage are: C: 0.14%, Cr: 9.06%, Co: 1.15%, Mo: 1.51%, Ni: 0.17 %, Si: 0.06%, Mn: 0.42%, V: 0.20%, N: 0.06%, Nb: 0.049%, B: 0.008%, and the rest are Fe and unavoidable impurity elements.

[0052] ① Preparation of metallographic samples:

[0053] a. Cut a block sample of 10mm×10mm×5mm by wire cutting method, quench it after austenitizing at 950°C for 5 hours, and prepare for subsequent grinding and polishing;

[0054] b. Coarse grinding of samples: Grind the samples sequentially with 180#→320#→600# silicon carbide water-resistant sandpaper. Rotate 90 degrees so that the new wear marks are vertical or nearly perpendicular to the previous wear marks, and grind until the new wear marks cover the previous wear marks. Use tap water as a lubricant when grinding ;

[0055] c. Fine grinding of the sample: Grind the coarsely ground sample on 1200# silicon ca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap