A battery charging mechanism

A battery charging and battery technology, applied in battery circuit devices, electric vehicle charging technology, charging stations, etc., can solve the problems of high labor cost, potential safety hazards, low efficiency, etc., to improve the efficiency of power exchange, and the action of power exchange is simple , the effect of smart structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

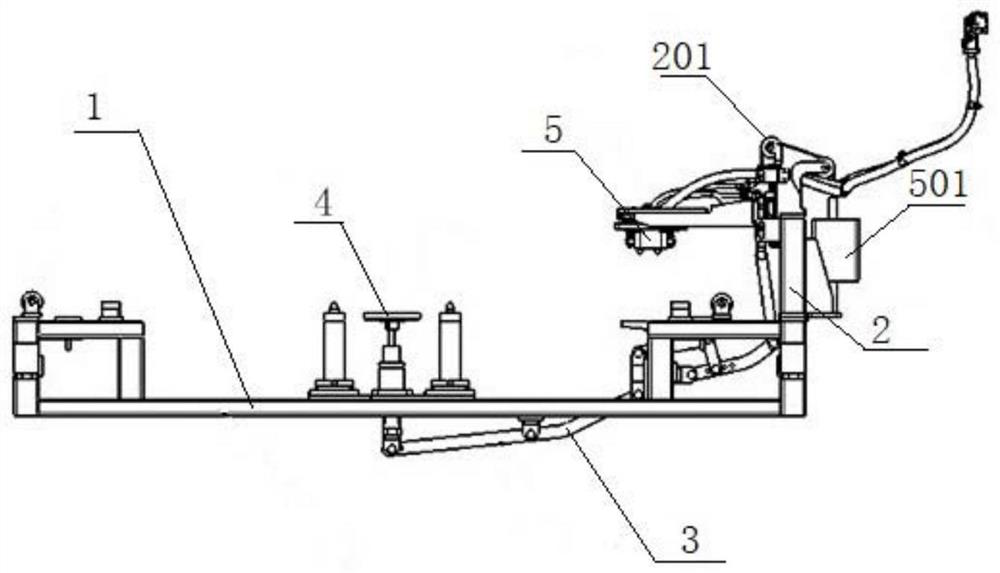

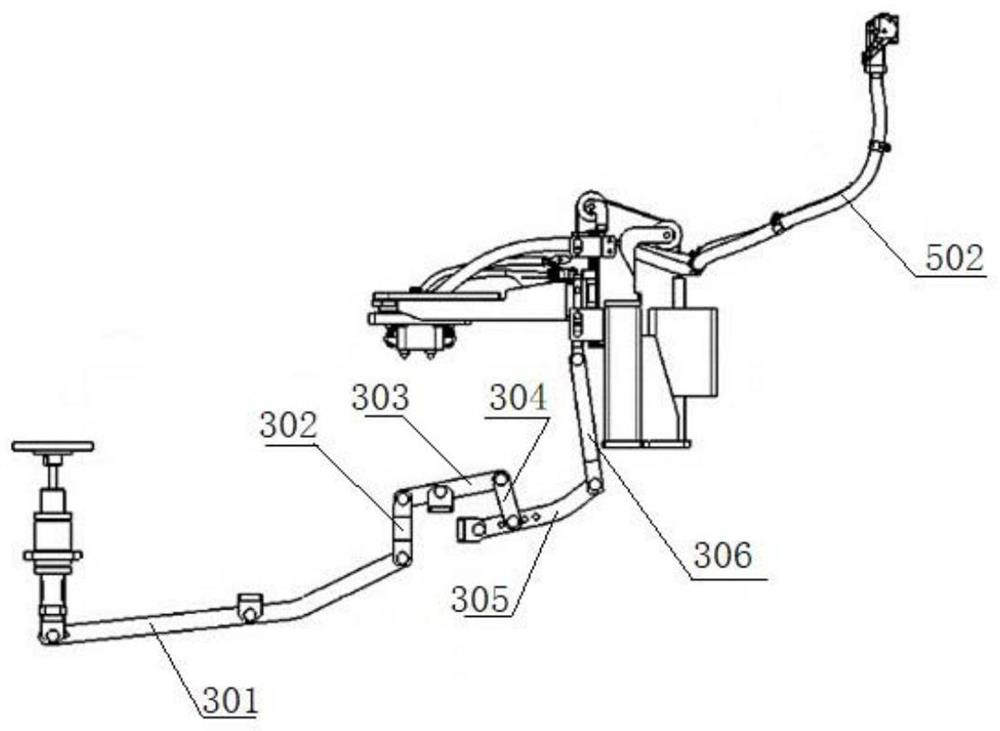

[0033] like Figure 1-5 As shown, the present invention provides a battery charging mechanism, comprising:

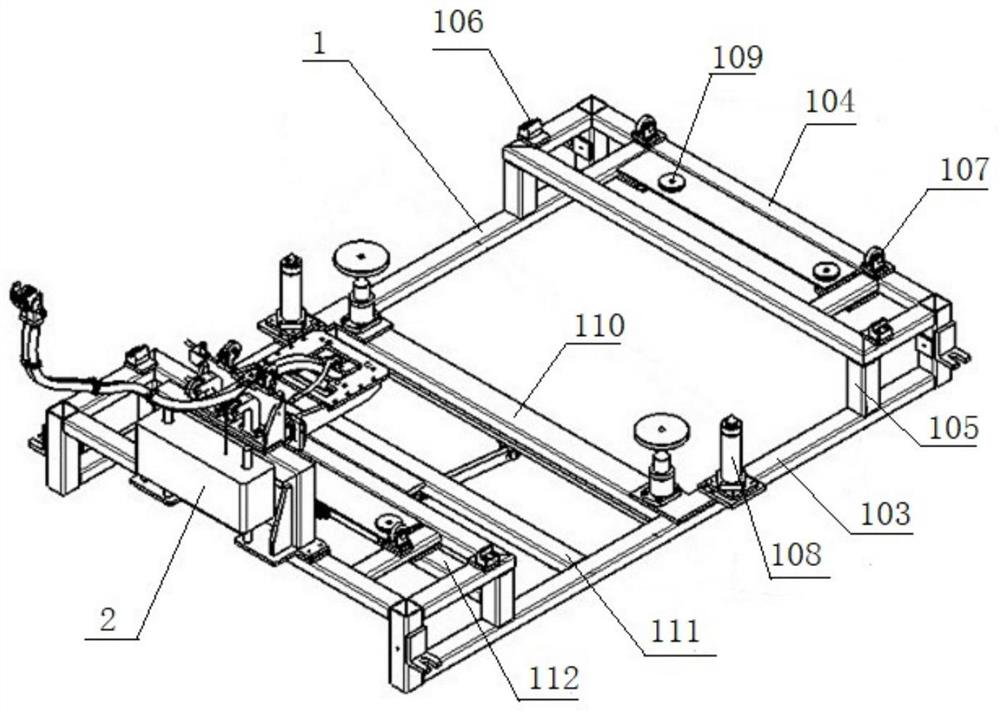

[0034] The support frame 1 is provided with guide rails and limit parts for placing batteries, such as figure 1 As shown, in this embodiment, the support frame 1 further includes a bottom frame 103 and two upper frames 104; wherein, the bottom frame 103 includes two horizontal bars arranged in parallel, and also has a third vertical connection with the two horizontal bars. A fixing rod 110 and a third fixing rod 112; an upper frame 104 is fixed to one end of the bottom frame 103 through the upright 105, and the other upper frame 104 is fixed to the other end of the bottom frame 103 through the upright 105. The two upper frames 104 form a The horizontal support surface is the place where the battery is finally charged. It should be noted that the figure shows that the number of uprights 105 is eight, that is, each of the four corners of the upper frame 104 is provided w...

Embodiment 2

[0049] like Figure 6-8 As shown, the battery charging mechanism provided by the present invention is applied in the battery charging library, and realizes the automation of the whole process of electric vehicle battery replacement.

[0050] The above-mentioned battery charging warehouse includes a container 10 as a warehouse body, a stacking trolley 7, a telescopic fork 8, several battery charging mechanisms, and a plurality of racks 6 for placing the battery charging mechanisms.

[0051] Four battery charging mechanisms are stacked on each shelf 6 in sequence, and each battery charging mechanism is detachably fixed on the shelf 6 through connectors. The three shelves 6 form a large charging matrix, and each charging unit corresponds to one For the battery charging mechanism, one side wall of the container 10 is set as the warehouse door of the charging warehouse, and a stacking trolley 7 is provided on the side of the charging matrix close to the warehouse door, and the stac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com