Circuit board and manufacturing method thereof

A production method and circuit board technology, applied in the directions of printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve the problems of loose adhesion, uneven color and uneven thickness of the cover film, and achieve tight adhesion, The effect of uniform color and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical content disclosed in the present invention more detailed and complete, reference may be made to the drawings and the following various specific embodiments of the present invention, and the same symbols in the drawings represent the same or similar elements. However, those skilled in the art should understand that the examples provided below are not intended to limit the scope of the present invention. In addition, the drawings are for illustrative purposes only and are not drawn to scale according to their actual size.

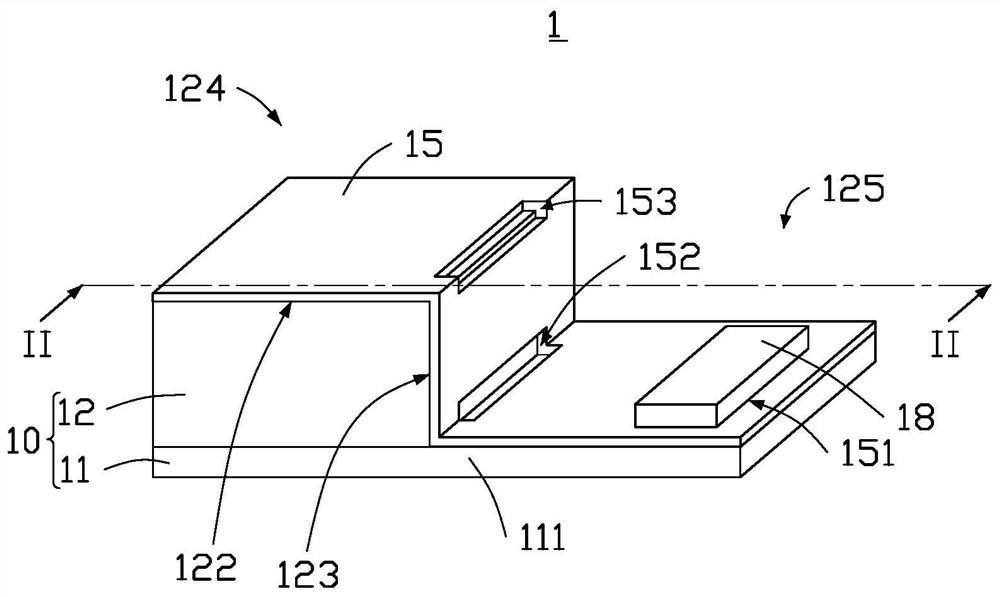

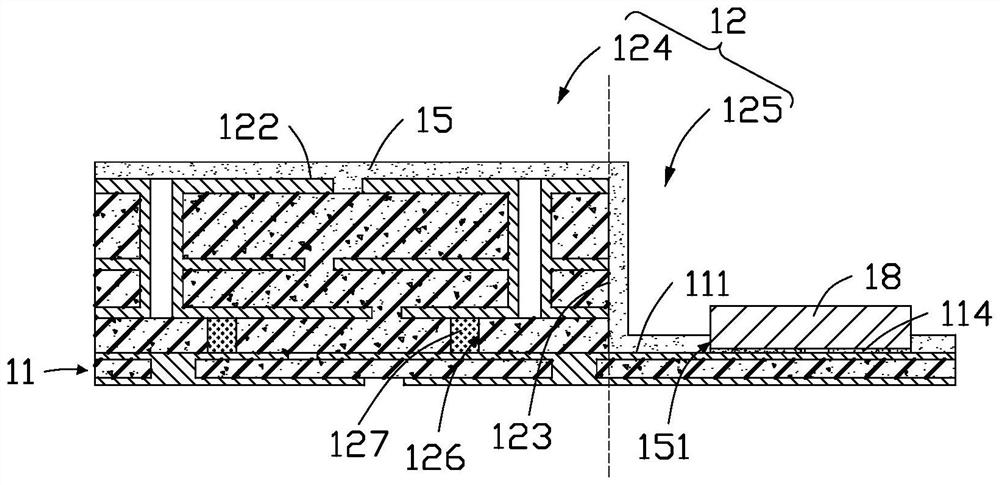

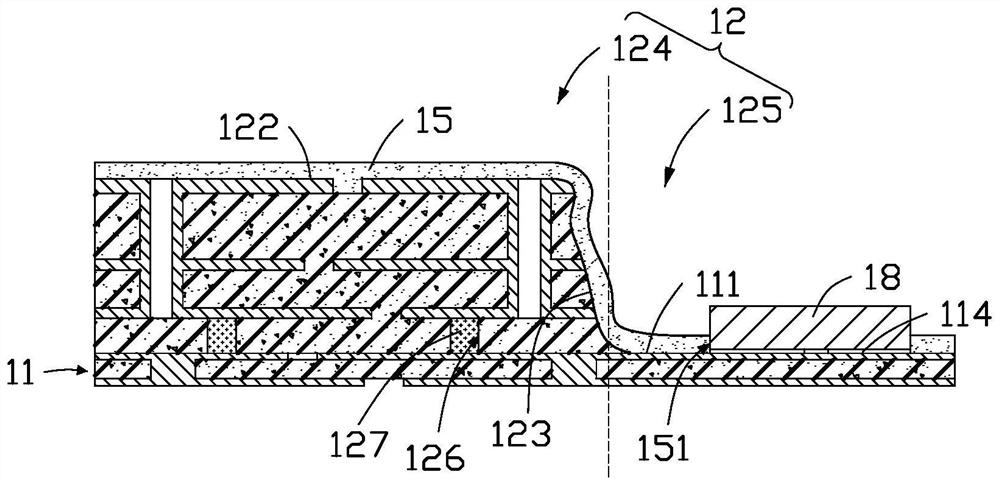

[0034] Such as figure 1 As shown, it is a three-dimensional schematic diagram of a circuit board 1 according to an embodiment of the present invention. Such as figure 2 As shown, it is a schematic cross-sectional view of the circuit board 1 along the direction II-II according to an embodiment of the present invention.

[0035] The circuit board 1 includes a main circuit substrate 10 and a cover film 15, the main circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com