Manufacture and winding equipment and winding method of galvanized steel strand

A galvanized steel strand and equipment technology, which is applied in the field of steel strand production, can solve problems such as loose strands, messy arrangement of strands, loose strand coils, etc., achieve tight attachment, convenient transportation, and prevent loosening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

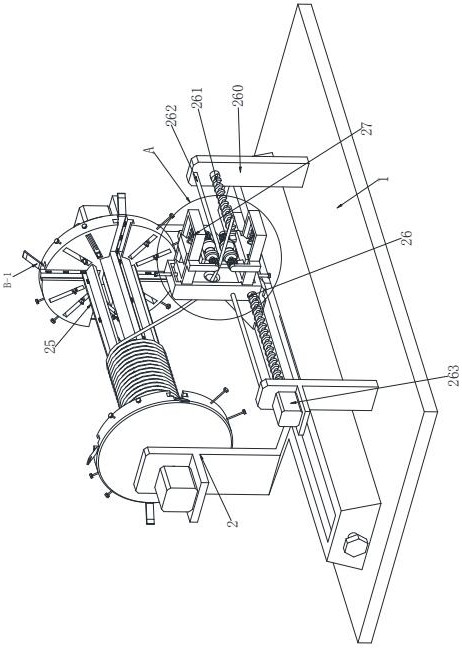

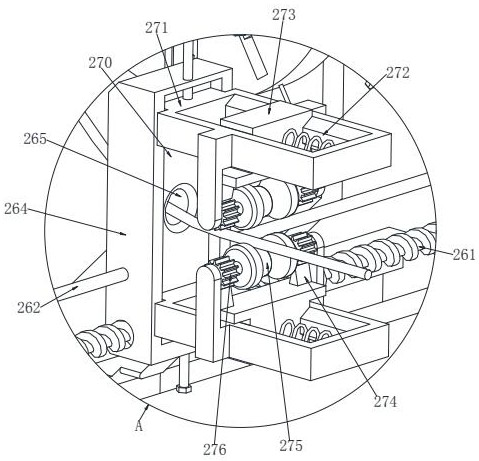

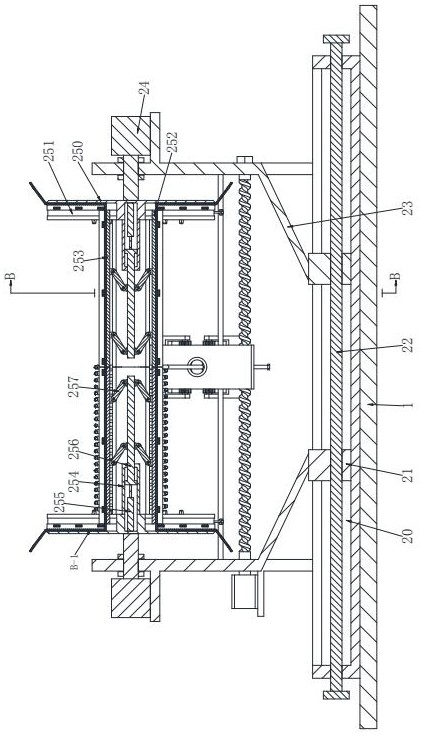

[0026] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0027] A galvanized steel strand manufacturing winding equipment, including a base 1 and a winding device 2, the upper surface of the base 1 is provided with a winding device 2; wherein: the winding device 2 includes a winding slideway 20, A winding slide 21, a winding screw 22, a winding support 23, a winding motor 24, a winding unit 25, a cable unit 26 and a tensioning unit 27, the upper surface of the base 1 is provided with a winding slide along its length direction. Road 20, two winding slides 21 are symmetrically arranged in the winding slide 20, a winding screw 22 is rotated in the winding slide 20, and the two ends of the winding screw 22 pass through the winding slide 20 At both ends, the winding screw 22 and the winding slide 21 are threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com