Concrete mixer

A concrete mixer and mixing drum technology, applied in the field of construction machinery, can solve the problems of raw materials not meeting the requirements, slow mixing speed, slow mixing speed, etc., and achieve the effect of improving the mixing effect, shortening the mixing time and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

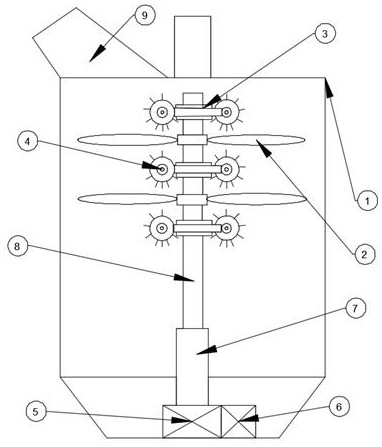

[0013] see figure 1 , the present invention provides a technical solution:

[0014] A concrete mixer, comprising a mixing drum 1 and a mixing shaft, the mixing shaft is vertically arranged at the center of the mixing drum 1, and also includes a mixing blade 2, a rolling bearing 3, a rotating wheel assembly 4, a lifting drive device 5 and a rotating drive device 6. The stirring shaft includes a fixed shaft 6, a movable shaft 7, and a feed port 8.

[0015] Wherein, the rotation driving device is connected with a transmission for controlling the rotation rate of the rotating wheel assembly.

[0016] Wherein, there are multiple groups of rotating wheel assemblies, which are arranged at intervals between the stirring blades.

[0017] Wherein, each rotating wheel assembly includes two rotating wheels.

[0018] Wherein, the top of the mixing drum is provided with a feeding port.

[0019] Although the embodiments of the present invention have been shown and described, those skille...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap