Temporary support frame for mounting assembled lattice type steel structure and use method

A technology for temporary support frames and steel structures, which is applied to the preparation of pillars, building structures, and building components on site. It can solve the problems of reducing the amount of temporary support frame materials, large consumption of turnover materials, and poor reusability. Achieve the effects of convenient hoisting, light weight, and convenient unloading operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the drawings and descriptions of the drawings.

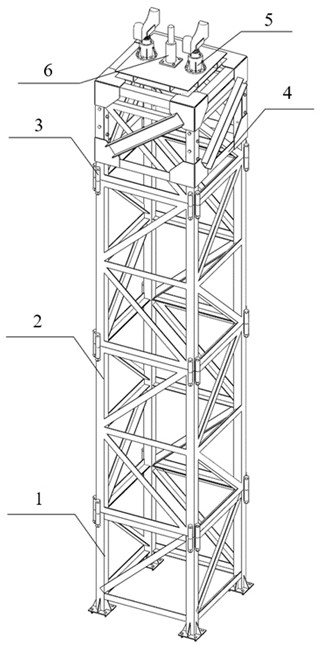

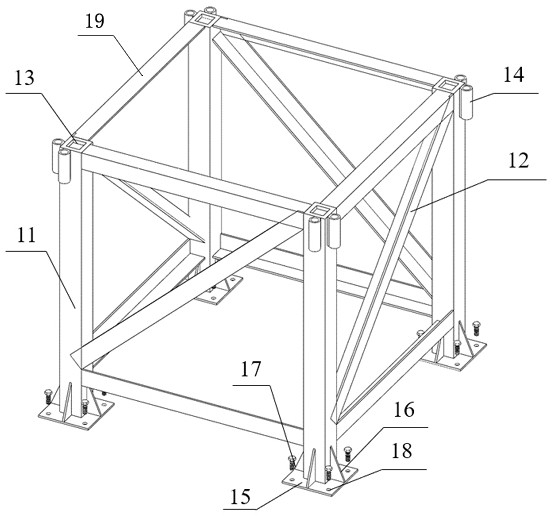

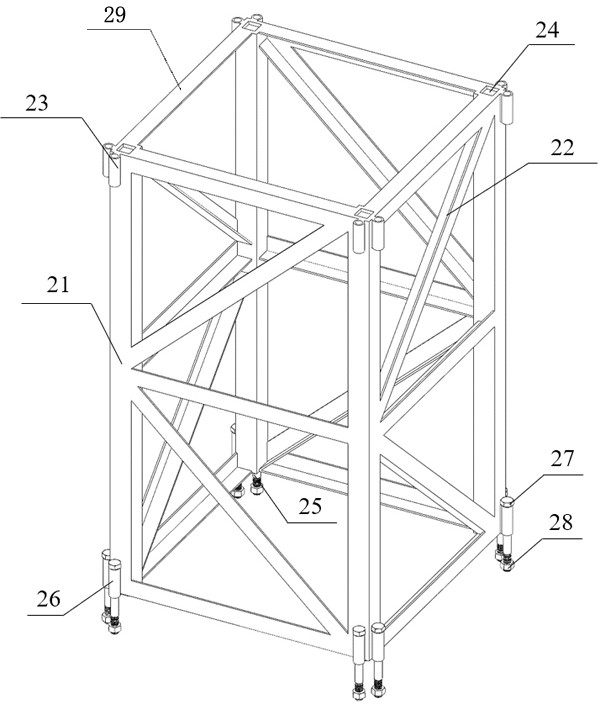

[0047] Such as figure 1 As shown, a temporary support frame for the installation of an assembled lattice steel structure is composed of a base section 1, a standard section 2, an adjustment section inner section 3, an adjustment section outer section 4, an adjustment top support 5, and a jack 6 for unloading; The seat section 1 reliably connects the support frame with the foundation; several standard sections 2 are combined into the main body of the support frame to meet the requirements of construction height; the inner section 3 and the outer section 4 of the adjustment section form the adjustment section for the height of the support frame. Preliminary adjustment of the height of the support frame; several adjustable top supports 5 provide support for the steel structure, and by changing the number and respective heights of the adjustable top sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com