Chemical process pump with adjustable bearing gland

A bearing gland and process pump technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluid, can solve the problem of increasing the radial runout value of the bearing, extruding the bearing diameter, and changing the length, etc. problems, to achieve the effect of smooth adjustment, improved bearing adaptation, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

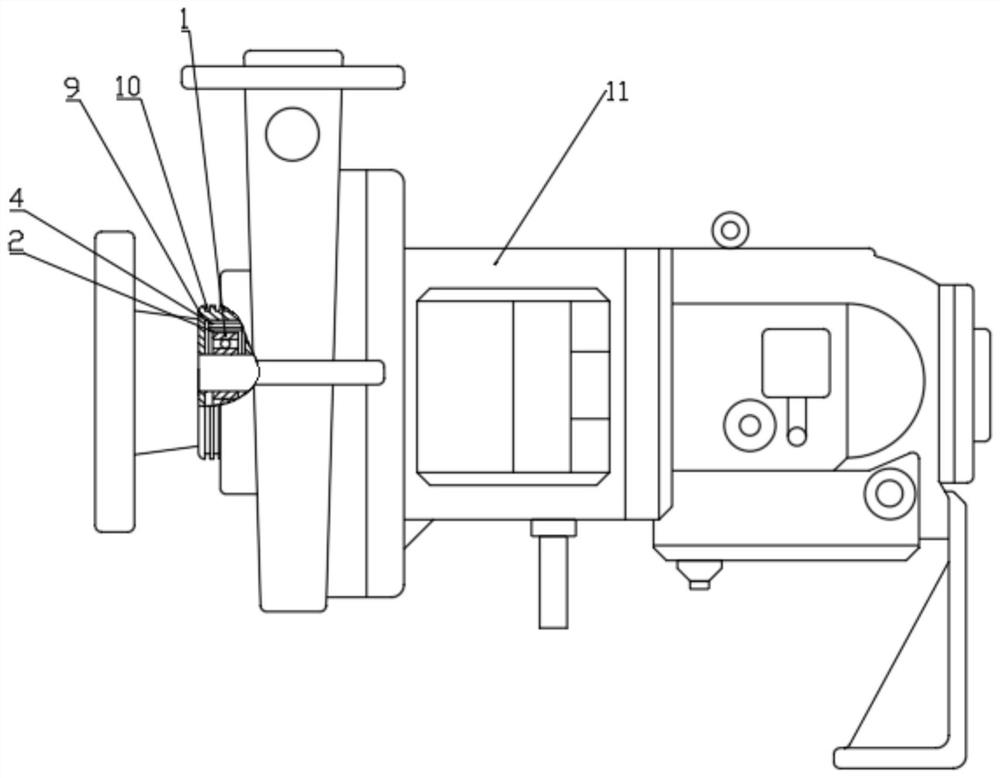

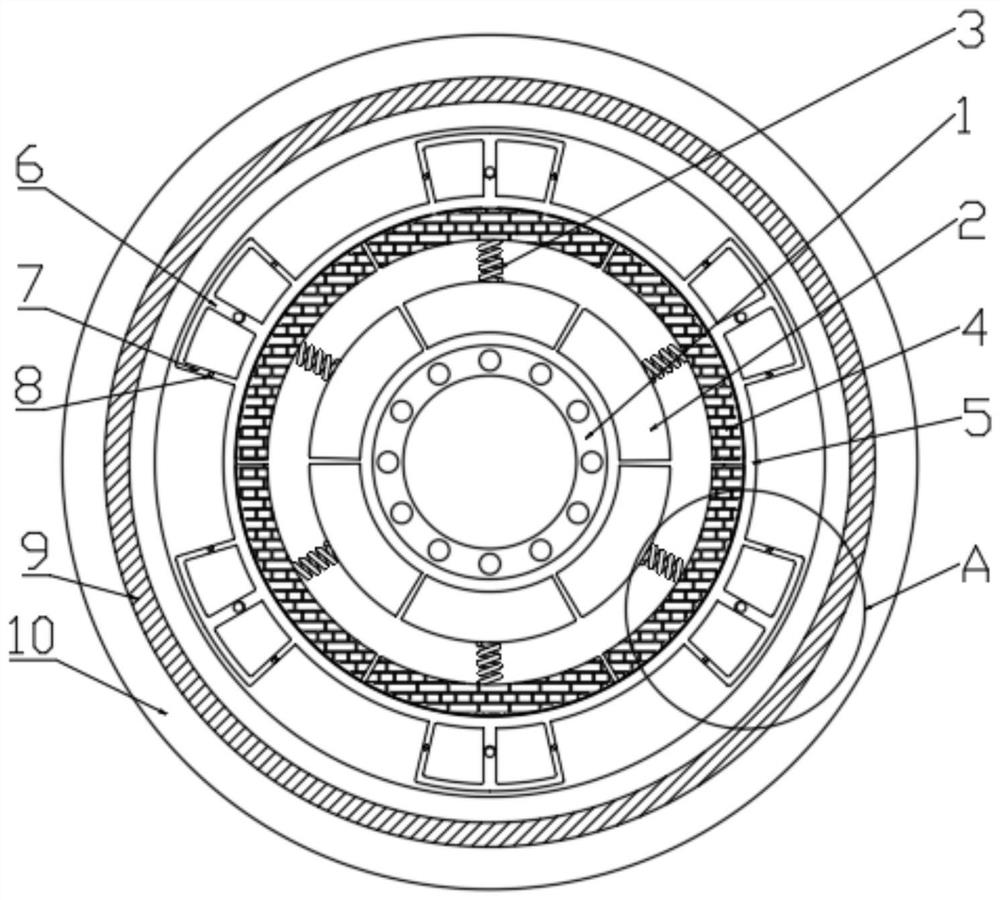

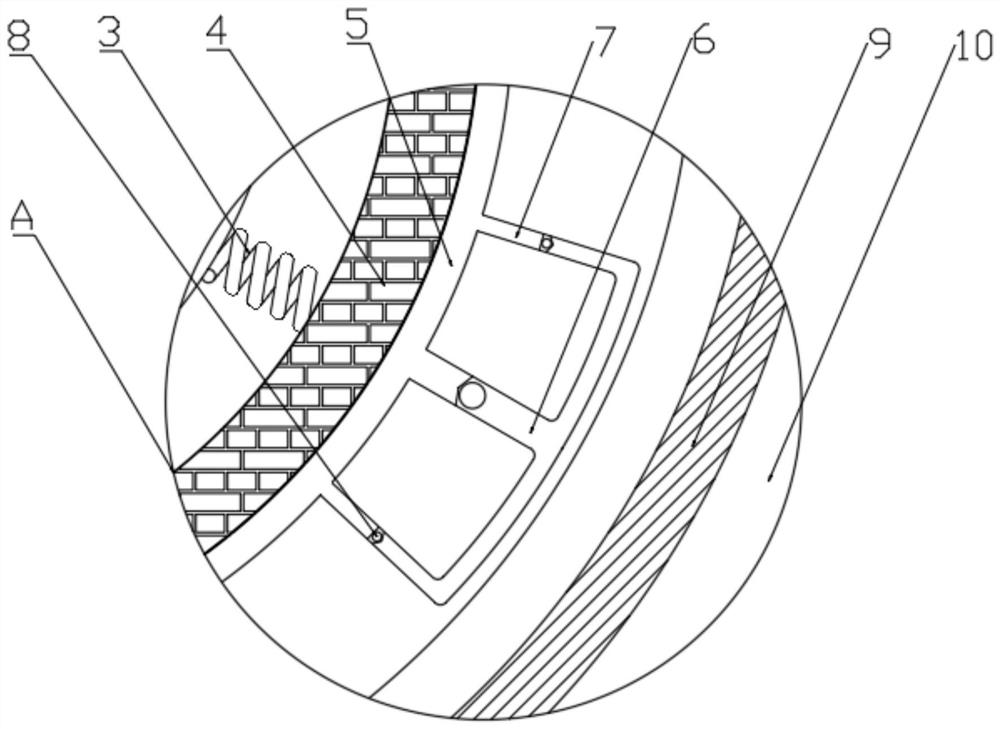

[0024] see Figure 1-6 , a chemical process pump with an adjustable bearing gland, comprising a process pump body 11, a bearing gland 9 and a bearing 1, a bearing 1 is installed in the process pump body 11 through the bearing gland 9, and the bearing 1 is set In the bearing gland 9, a first buffer layer and a second buffer layer are arranged between the bearing 1 and the bearing gland 9, and the first buffer layer and the second buffer layer are arranged along the radial direction of the bearing 1. Arranged sequentially from the inside to the outside; the second buffer layer includes an air flow pipe 5, a main flow channel 6 and a side flow channel 7, the air flow pipe 5 is arranged on the periphery of the first buffer layer, and the air flow pipe 5 is also communicated with A plurality of main channels 6, the side of the main channel 6 is also provided with a side channel 7, and the two ends of the side channel 7 are respectively connected with the main channel 6 and the air ...

Embodiment 2

[0029] In order to further improve the practicability of this design, improvements have been added on the basis of Embodiment 1, the improvements are: please refer to Figure 1-6 , the first buffer layer includes a first movable block 2 and a second movable block 4, the number of the first movable block 2 and the second movable block 4 is multiple, and each first movable block 2 is elastically The connecting piece is connected with the second movable block 4 corresponding to the first movable block 2; the airflow pipe 5 is fitted on the outside of the second movable block 4; the first movable block 2 is fitted on the bearing 1 outside.

[0030] The elastic connector is the first spring 3 .

[0031] The setting of the first buffer layer can improve the resistance of the design to the radial runout of the bearing;

[0032] Specifically, when the bearing runs offset, it will first squeeze the first movable block 2, and then through the elastic action of the first spring 3, part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com