Fault detection method and system for X-ray generating device of thickness gauge

A generation device, X-ray technology, applied in the computer field, can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

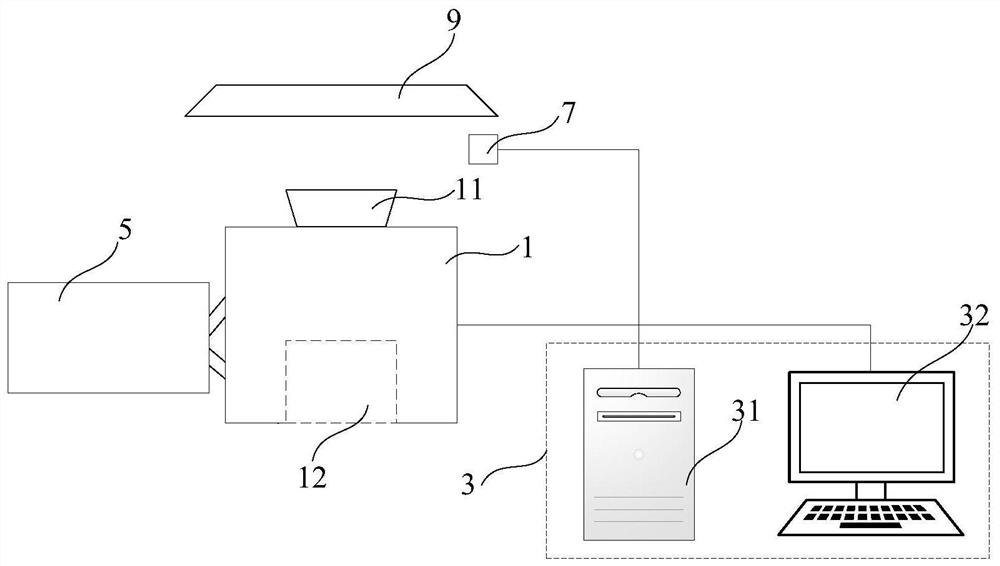

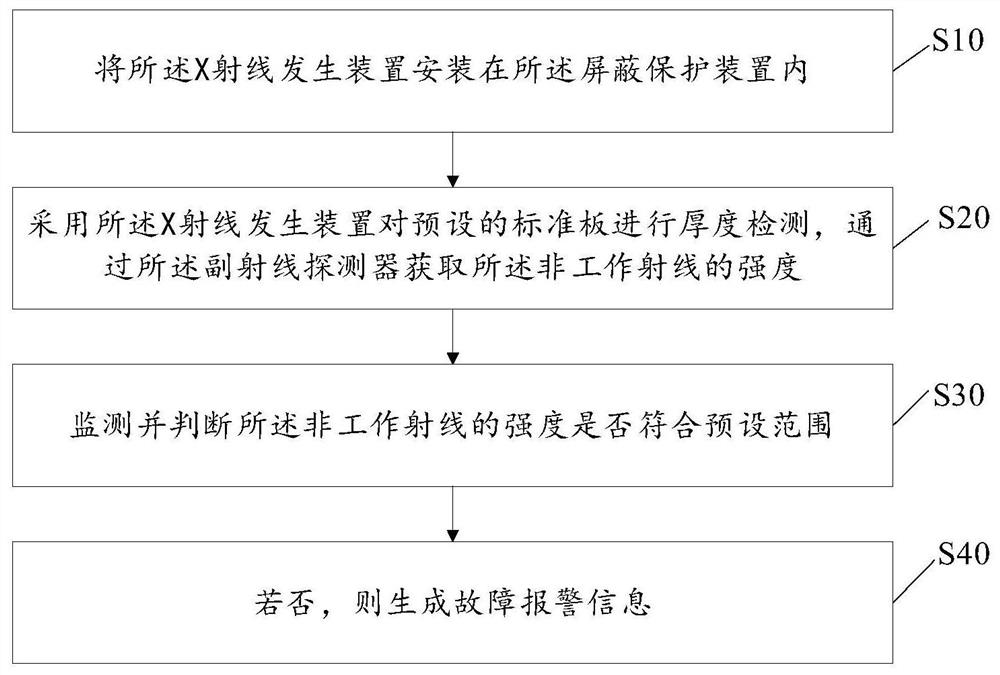

[0037] See figure 2 , figure 2 A flow chart of a fault detection method for an X-ray generating device of a thickness gauge provided by the first embodiment of the present invention is shown. Based on the above detection platform, the implementation steps of the method are as follows:

[0038] Step S10: installing the X-ray generating device in the shielding protection device.

[0039] In step S10, the installation method is determined by the structure of the shielding protection device. For example, there is a corresponding base in the shielding protection device, and the X-ray generating device is fixed by bolts or screws driven by a motor, and the X-ray emitting end faces the shielding device. The opening position of the protective device.

[0040] In addition, before performing step S10, the cooling system needs to be connected to the X-ray generating device, that is, the X-ray generating device is provided with a cooling pipeline, and the heat in the X-ray generating...

no. 2 example

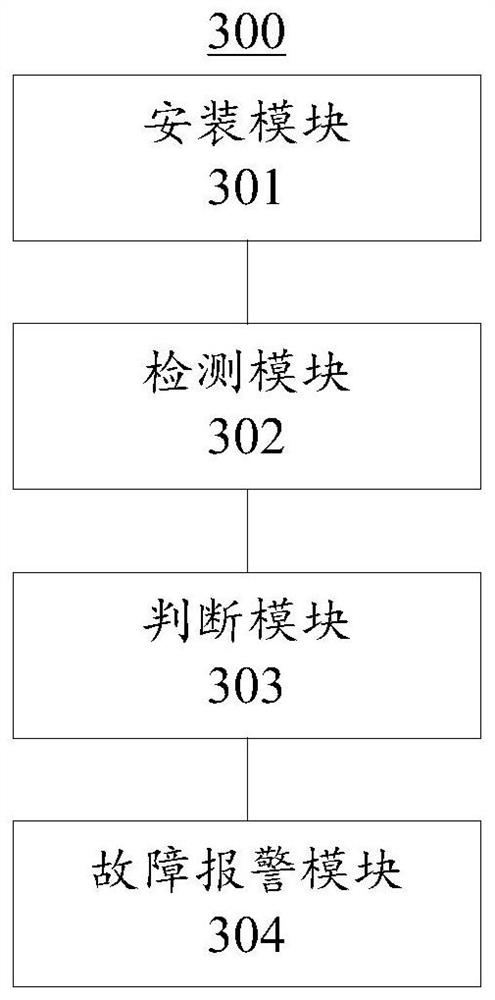

[0050] see image 3 , based on the same inventive concept, the second embodiment of the present invention provides a fault detection system 300 for an X-ray generating device of a thickness gauge.

[0051] The fault detection system 300 of the X-ray generating device of the thickness gauge is applied to the detection platform in the first embodiment above, and the detection platform includes: a shielding protection device, an analysis device and a secondary ray detector; There is an opening, and the opening is used to pass through the working rays of the X-ray generating device; the analysis device is connected to the secondary ray detector, and the secondary ray detector is used to detect the intensity of non-working rays, and the analysis device For monitoring the intensity of the non-working rays; the system 300 includes:

[0052] An installation module 301, configured to install the X-ray generating device in the shielding protection device;

[0053] The detection module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com