A high-precision sampling system for color masterbatch production line

A sampling system and high-precision technology, applied in sampling, sampling devices, instruments, etc., can solve problems affecting the accuracy of test results, sampling and testing of color masterbatch finished products, cumbersome operation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

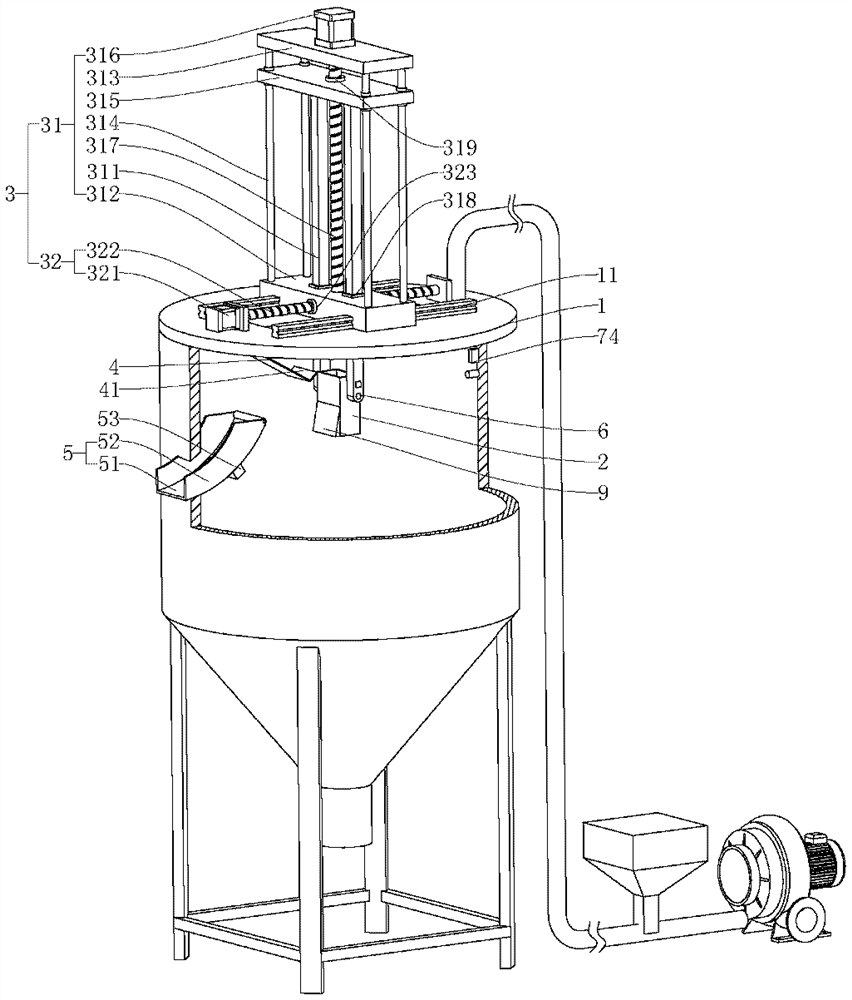

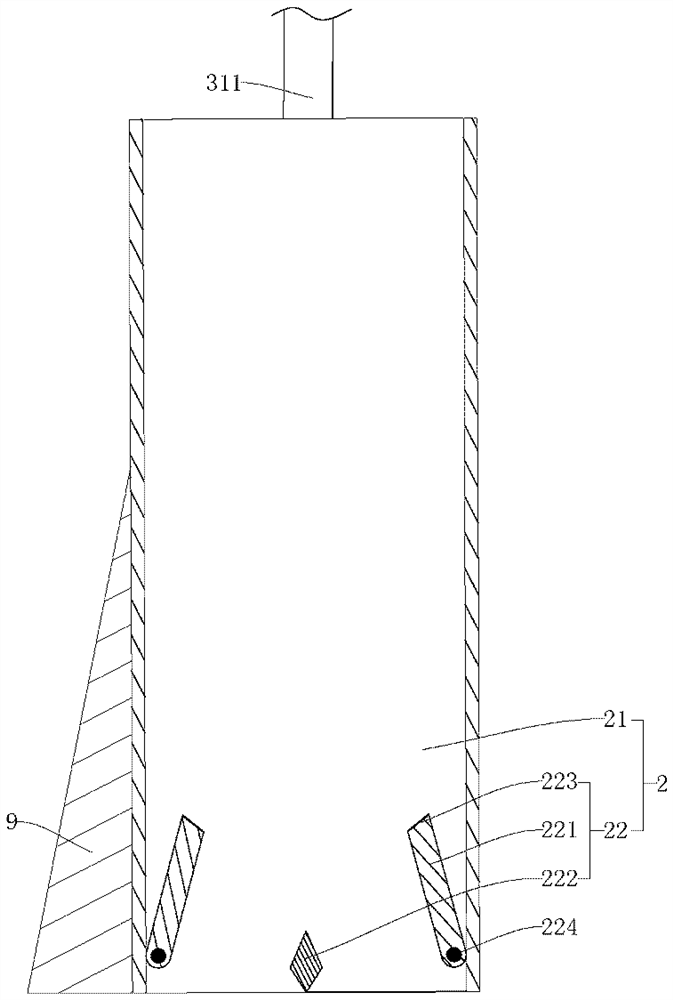

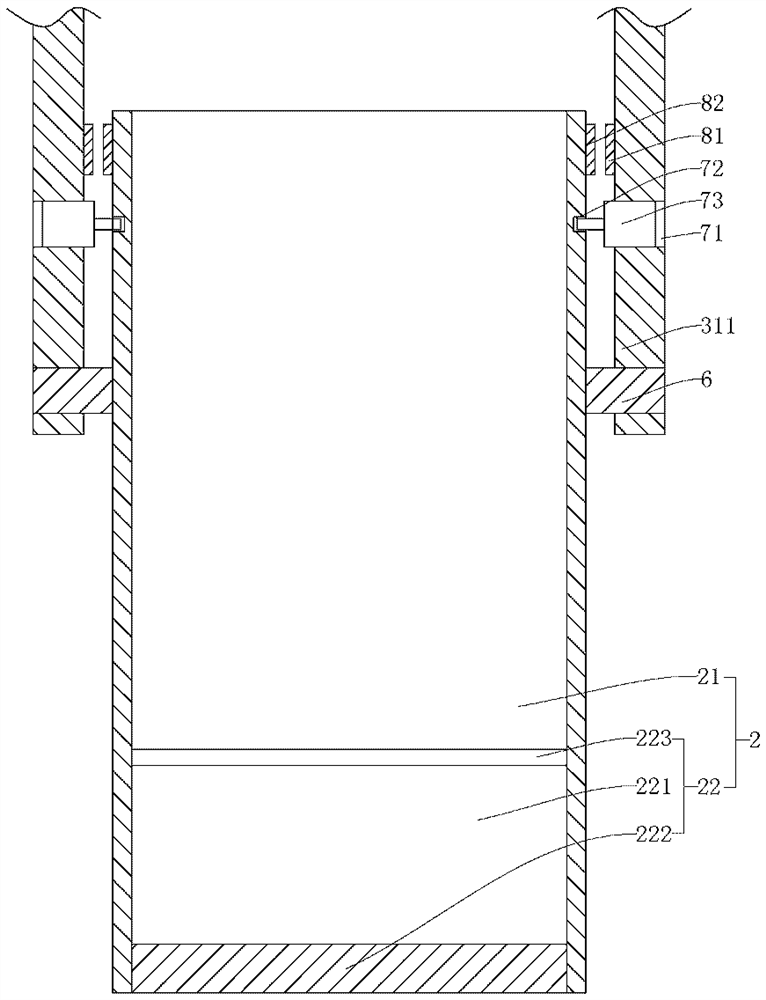

[0032] The following is attached Figure 1-4 The application is described in further detail.

[0033] The embodiment of the present application discloses a high-precision sampling system for a color masterbatch production line.

[0034] refer to figure 1 , the high-precision sampling system of the color masterbatch production line includes a storage tank 1 and a sampling device, wherein the color masterbatch is introduced into the storage tank 1 from the top of the storage tank 1 by air for storage, and is stored by the storage tank 1 during use. The discharge port at the bottom of the barrel 1 is taken out for use, the sampling device is set on the top of the storage barrel 1, and the sampling device can be inserted into the color masterbatches of different depths in the storage barrel 1, and the color masterbatches of different depths are quantitatively The pellets are lifted for testing personnel to take samples for testing.

[0035] The sampling device includes a sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com