Display device and preparation method thereof

A technology for display devices and display devices, which is applied in nonlinear optics, instruments, optics, etc., and can solve problems such as information leakage of display screens.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] One embodiment of the present invention provides a method for manufacturing a display device, comprising the following steps:

[0082] Provide the substrate;

[0083] forming a display device on the substrate;

[0084] forming a first alignment layer on a side of the display device away from the substrate;

[0085] forming a liquid crystal layer on the side of the first alignment layer away from the display device;

[0086] Wherein, the initial alignment angle of the liquid crystal layer relative to the display device is 0-30 degrees; or, the initial alignment angle of the liquid crystal layer relative to the display device is 60-90 degrees.

[0087] In one embodiment, further comprising the step of providing a cover plate;

[0088] The steps of forming the liquid crystal layer include:

[0089] Covering the cover plate on the first alignment layer, and forming an accommodation cavity between the cover plate and the first alignment layer;

[0090] A liquid crystal ...

Embodiment 1

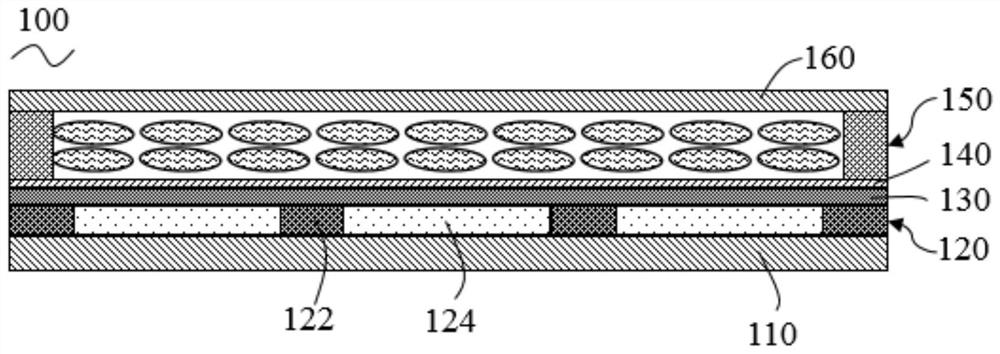

[0095] Example 1 as figure 1 The shown display device 100 and its manufacturing method

[0096] 1) A substrate 110 is provided, and an OLED display device 120 is prepared on the substrate 110 . The display device 120 includes patterned pixel isolation walls 122 and a plurality of light-emitting pixel units 124 separated by the pixel isolation walls 122 .

[0097]2) On the surface of the OLED display device 120, a 30 nm thick gallium oxide thin film is prepared by using a sol-gel (sol-gel method) process as the planar layer 130 . Due to the good light transmittance and strong compactness of the gallium oxide thin film, it can be used not only as a flat layer but also as an encapsulation layer of an OLED display device.

[0098] 3) Coating a layer of polyimide (PI) film with a thickness of 10 nm on the flat layer 130 and preparing an alignment angle of 2° to obtain a first alignment layer 140 with an alignment direction.

[0099] 4) covering the first alignment layer 140 with ...

Embodiment 2

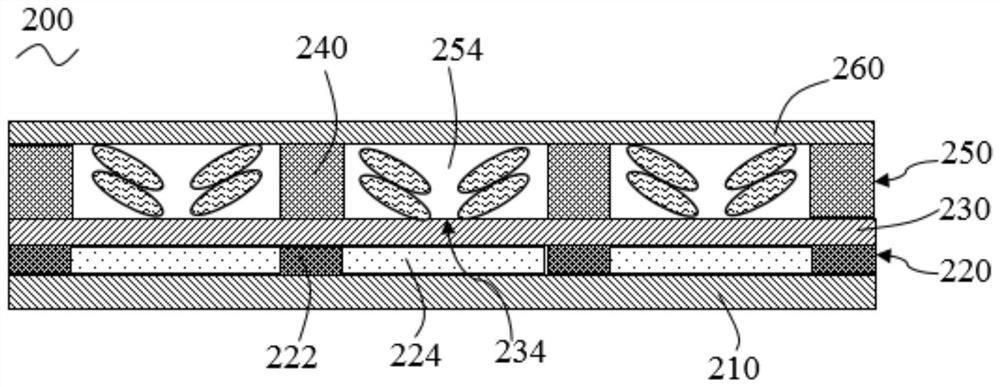

[0101] Example 2 as figure 2 The shown display device 200 and its manufacturing method

[0102] 1) A substrate 210 is provided, and an LCD display device 220 is prepared on the substrate 210 . The display device 220 includes patterned pixel isolation walls 222 and a plurality of light-emitting pixel units 224 separated by the pixel isolation walls 222 .

[0103] 2) On the surface of the LCD display device 220, prepare a layer of 30nm thick PMMA (polymethyl methacrylate) film with a scraping process, then use aluminum as a material, and use an evaporation process to prepare a patterned film on the PMMA film layer. The light-blocking wall 240 , the position of the light-blocking wall 240 corresponds to the position of the pixel isolation wall 222 of the LCD display device 220 , and the height of the light-blocking wall 240 is 50 nm.

[0104] 3) The light-blocking wall 240 divides the surface of the PMMA film into a plurality of regions, wherein each region is divided into a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com