Automatic assembling equipment for self-locking tuning screw

A tuning screw and automatic assembly technology, which is applied in the direction of electrical components, circuits, waveguide devices, etc., can solve the problems of low efficiency, lack of buffer function and fixed base, etc., and achieve the effect of high efficiency and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

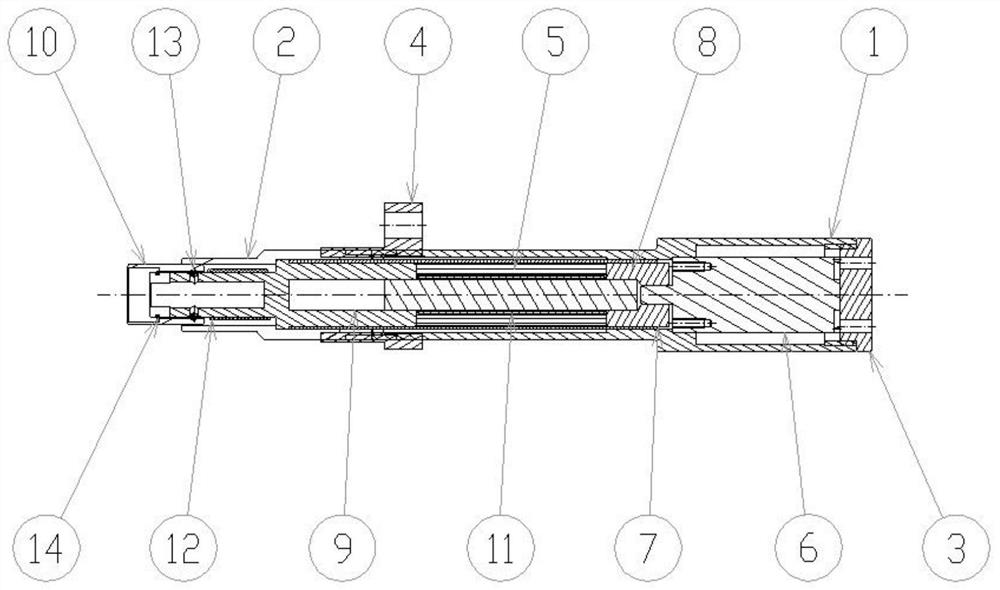

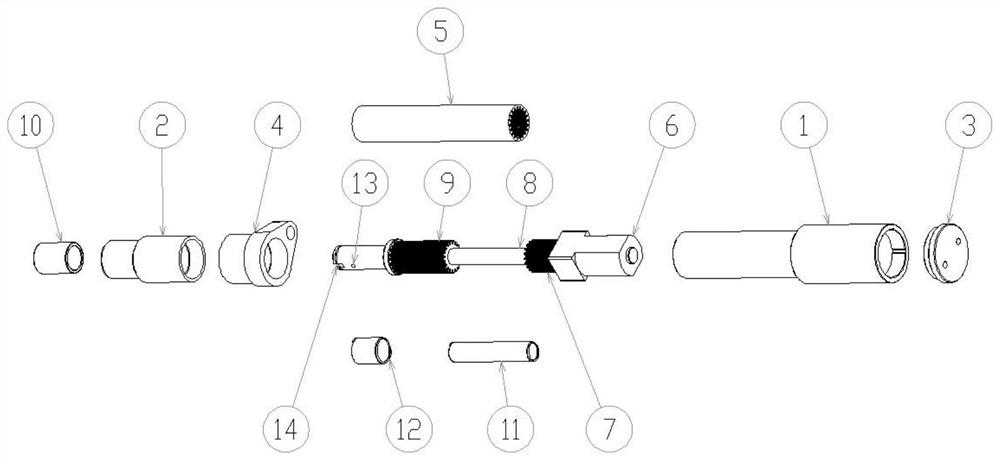

[0021] refer to Figure 1-2 , a self-locking tuning screw automatic assembly equipment, including an upper body 1, a lower body 2 and a mounting seat 4, the lower end of the upper body 1 and the upper end of the lower body 2 are respectively connected to the two ends of the mounting seat 4, the upper end of the upper body 1 A deceleration motor cavity is provided, and a deceleration motor 6 is fixedly installed on the inner wall of the deceleration motor cavity. The upper end of the upper body 1 is connected with a surface cover 3, and the surface cover 3 cooperates with the deceleration motor 6. The output shaft of the deceleration motor 6 An output gear 7 is welded on the top, and the output gear 7 is fixedly connected to the upper end of the inner gear shaft 5, and a spring guide rod 8 is installed on the output gear 7, and a compression spring 11 is set on the outer side of the spring guide rod 8, and the inner gear shaft 5 The lower end is connected with a torque shaft 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com