Self-cleaning device and cleaning method in waste gas treatment process

A technology for waste gas treatment and self-cleaning, applied in separation methods, chemical instruments and methods, transportation and packaging, etc., can solve problems such as inability to clean the filter screen, inability to effectively filter waste gas, and blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

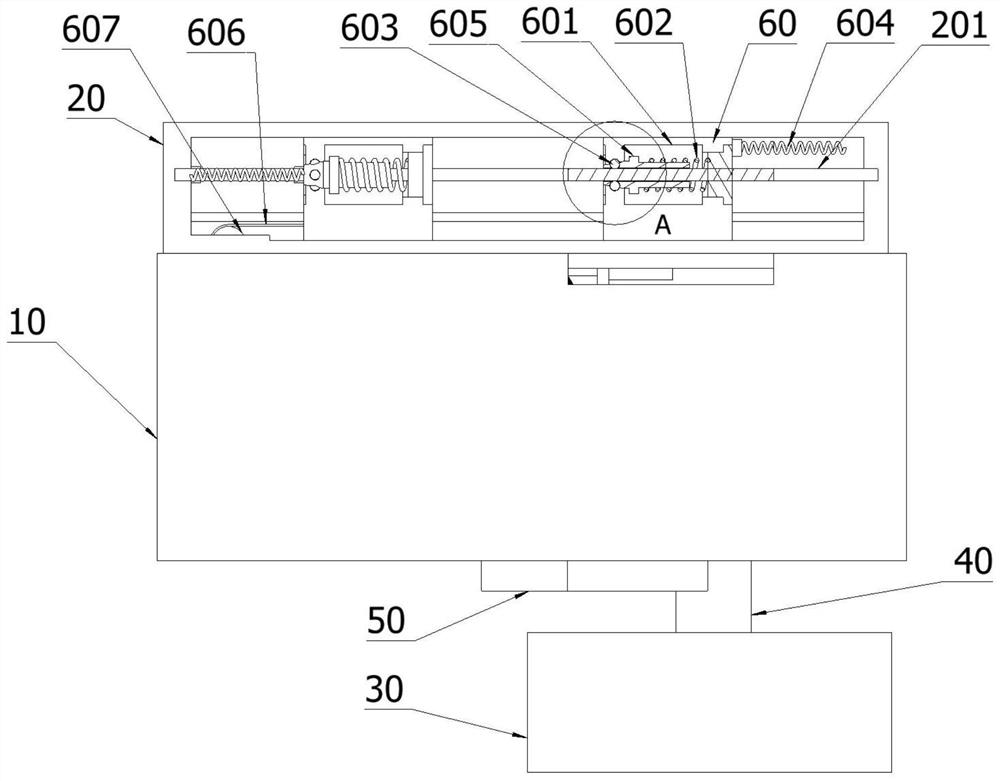

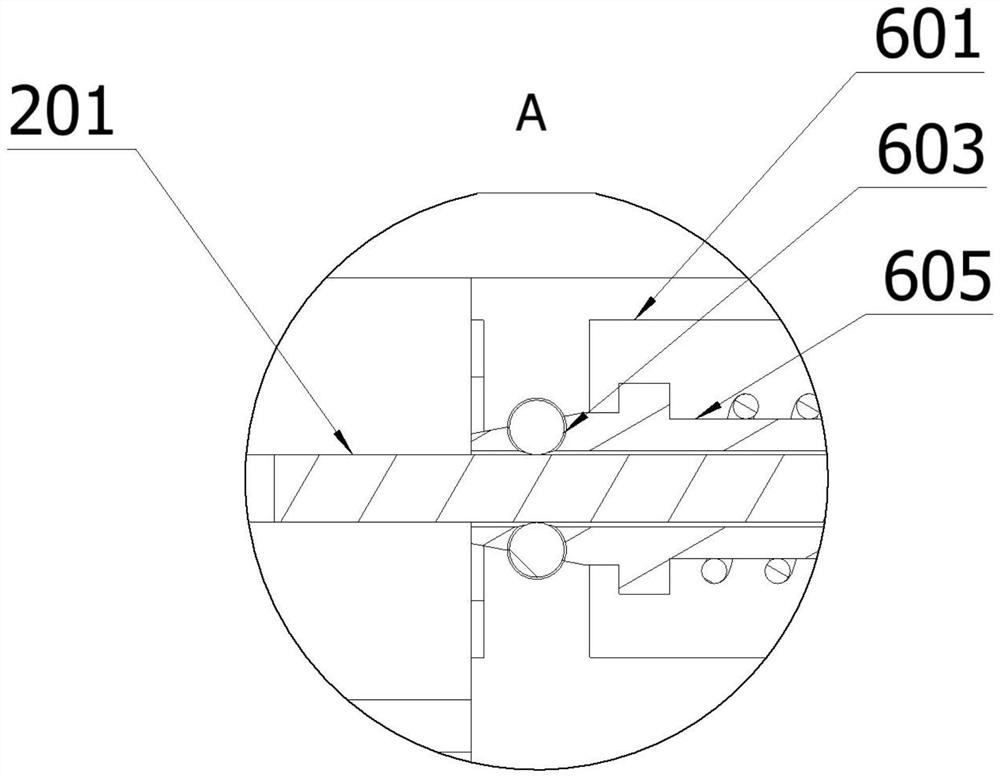

[0050] Such as figure 1 , 2 , 4, this embodiment discloses a self-cleaning device in the waste gas treatment process, including: an outer channel 10, an inner channel 101, an auxiliary ventilation plate 102, an air outlet channel 103, a housing 20, a driving device 60, a cleaning Device 70, closing device 90, the inside of the outer passage 10 is hollow; the inner passage 101 is arranged inside the outer passage 10, the inner passage 101 is connected with the outer passage 10, and the inside of the inner passage 101 is hollow; the auxiliary ventilation plate 102 is arranged in the inner passage The lower surface of 101, the auxiliary ventilation plate 102 is connected with the inner channel 101; the air outlet channel 103 is arranged on the right side of the auxiliary ventilation plate 102, and there is a distance between the air outlet channel 103 and the auxiliary ventilation plate 102, and the inside of the air outlet channel 103 It is hollow, and a filter screen 80 is arr...

Embodiment 2

[0061] Same as Embodiment 1, as shown in Figures 6 and 7, one end of the control rod 903 is also connected to the cover plate 105. The circular hole is matched, the cover plate 105 is connected with the driving device 60 in the right position, the adjustment frame 104 is connected with the driving device 60 in the left position, and the adjustment frame 104 approaches the filter screen 80 when driven by the left driving device 60 The cleaning device 70 cleans near the surface of the filter screen 80 , and drives the right side driving device 60 to move through the connecting belt 606 when the left driving device 60 moves and closes the cover plate 105 to the circular hole of the air outlet channel 103 . When the cover plate 105 moves through the control rod 903, the control rod 903 drives the connecting plate 902 to move to the right through the gear, so that the originally closed closing plate 901 is opened, and the exhaust gas can pass through the auxiliary ventilation plate ...

Embodiment 3

[0063] Such as Figure 8 , 9 As shown, the embodiment of the present invention also discloses a cleaning method for a self-cleaning device in the waste gas treatment process, including the following steps:

[0064] The external air supply pipe is connected with the external channel 10, and the waste gas is passed into the external channel 10 through the air supply pipe. After entering the external channel 10, the exhaust gas passes through the auxiliary ventilation plate 102 and the air outlet channel 103 to divide the exhaust gas into two streams;

[0065] The exhaust gas entering the auxiliary ventilation plate 102 continues to move to the right through the filter screen 80 to filter the exhaust gas impurities, and the filtered exhaust gas flows to the air outlet channel 103. Since the sealing device 90 inside the air outlet channel 103 is still in a closed state at this time, the filtered exhaust gas Do not enter the air outlet channel 103 and diverge to the periphery of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap