Non-circular ring-like thin-walled part machining process and thin-walled part clamping tool thereof

A technology of thin-walled parts processing and thin-walled parts, which is applied in the direction of metal processing machinery parts, metal processing equipment, clamping, etc., can solve the problems of poor guarantee of wall thickness and dimension accuracy, parts cannot be overheated, and titanium alloy materials are expensive, etc. Achieve the effect of reducing manual workload, improving processing accuracy and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

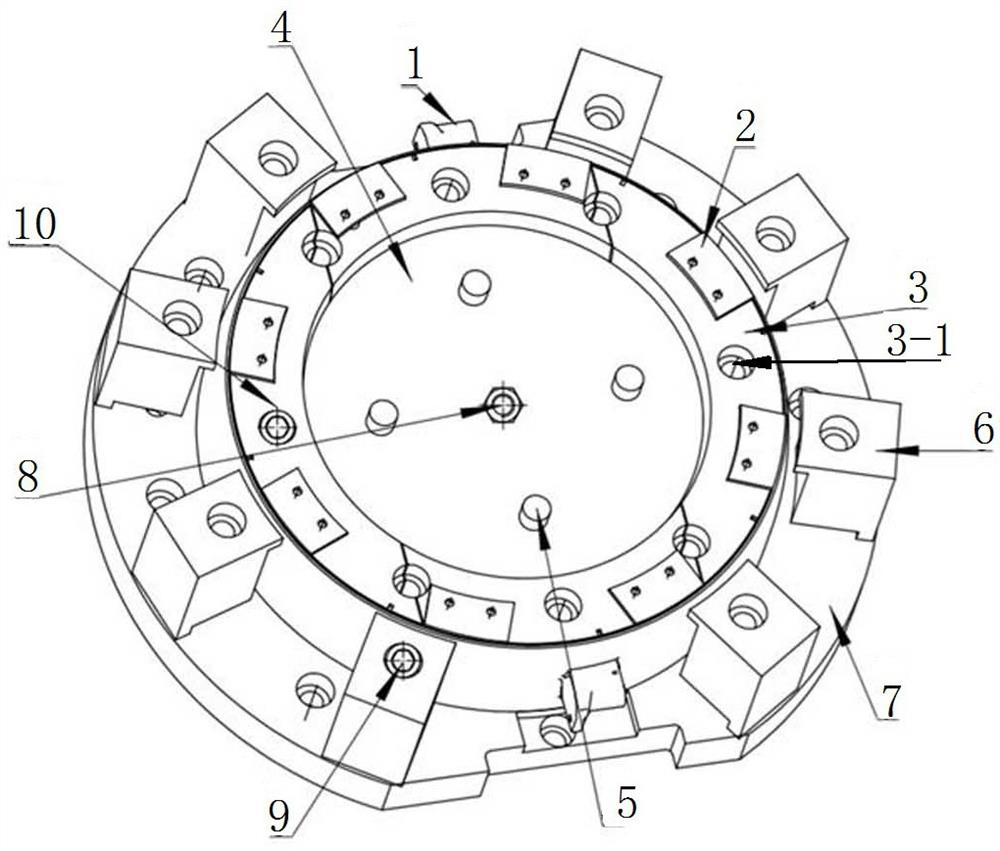

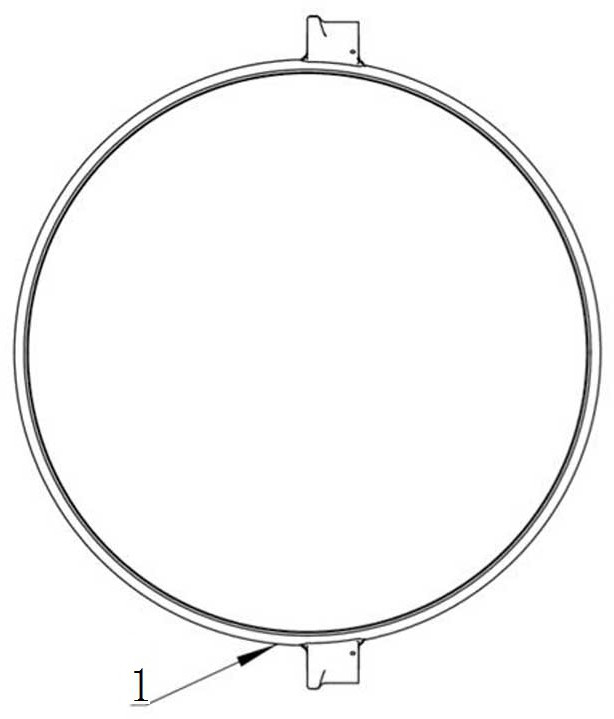

[0030] Non-circular annular thin-walled parts processing technology, the processing steps are as follows: 1) Shape positioning: place the workpiece to be processed on the tooling base plate 7 of the thin-walled part clamping tool, fix the outer ring pressure plate 6 on the tooling base plate 7, Compress the outer blank of the workpiece to be processed, and process the inner wall of the workpiece to be processed;

[0031] 2) Inner shape processing: 2.1) Rough inner shape: T50R6 rough inner shape is used, each cut is 0.5, and the margin is 0.3mm;

[0032] 2.2) Semi-fine inner shape: use T50R6 semi-fine inner shape, cut 0.45mm per cut, and leave a margin of 0.05mm;

[0033] 2.3) Fine inner shape: finish the inner shape with T50R6, the allowance is 0, and the inner shape is processed in place;

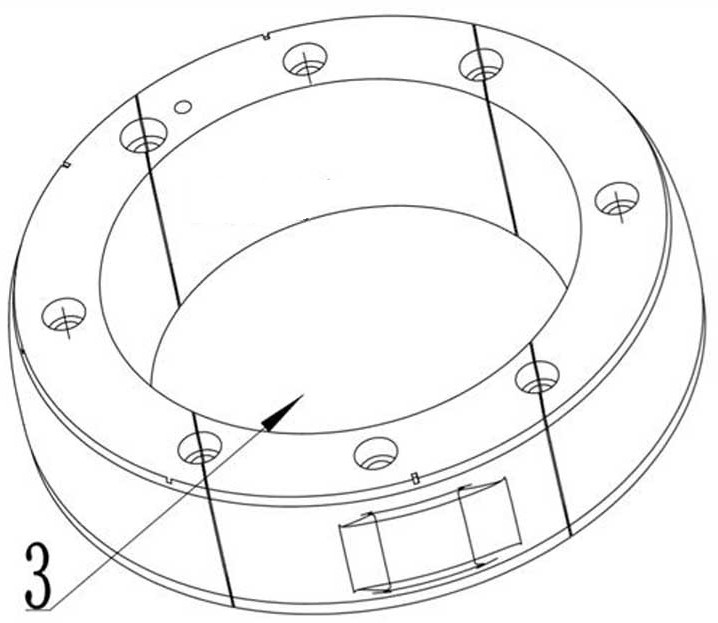

[0034] 3) Inner shape positioning: first place each detachable part of the clamping block 3 of the thin-walled part clamping tool in turn on the inner shape of the workpiece to be process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com