A cyber-physical monitoring and management system for workshops

A technology for monitoring management and workshop information, applied in the general control system, control/regulation system, program control, etc., can solve problems such as difficulties in seeking help for failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

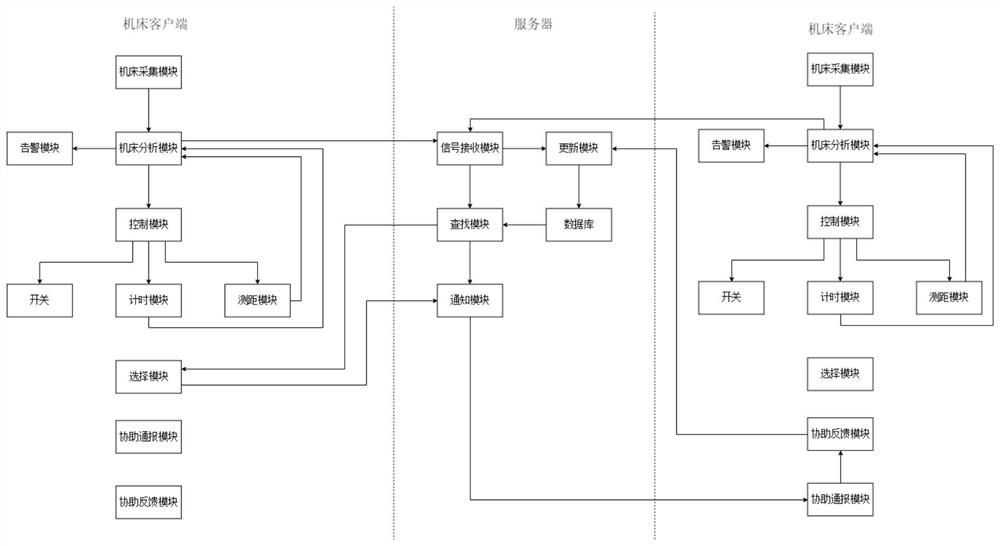

[0048] A workshop information physical monitoring and management system, such as figure 1 As shown, it includes a machine tool client and a server; the machine tool client includes a machine tool acquisition module, a machine tool analysis module, an assistance notification module, an assistance feedback module, an alarm module, a control module, and a timing module; the server includes a signal receiving module, an update modules, lookup modules, database and notification modules.

[0049] The machine tool collection module is used to collect the relevant data of each part on the machine tool, and send the measured information of the machine tool to the machine tool analysis module;

[0050] The machine tool analysis module is used to receive the machine tool actual measurement information sent by the machine tool acquisition module, calculate the machine tool fault information according to the machine tool actual measurement information, and send the machine tool fault infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com