Load distribution adjustment method based on circulating water system operation mode

A technology of circulating water system and operation mode, applied in instruments, data processing applications, forecasting, etc., can solve problems such as the safety risk of switching pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

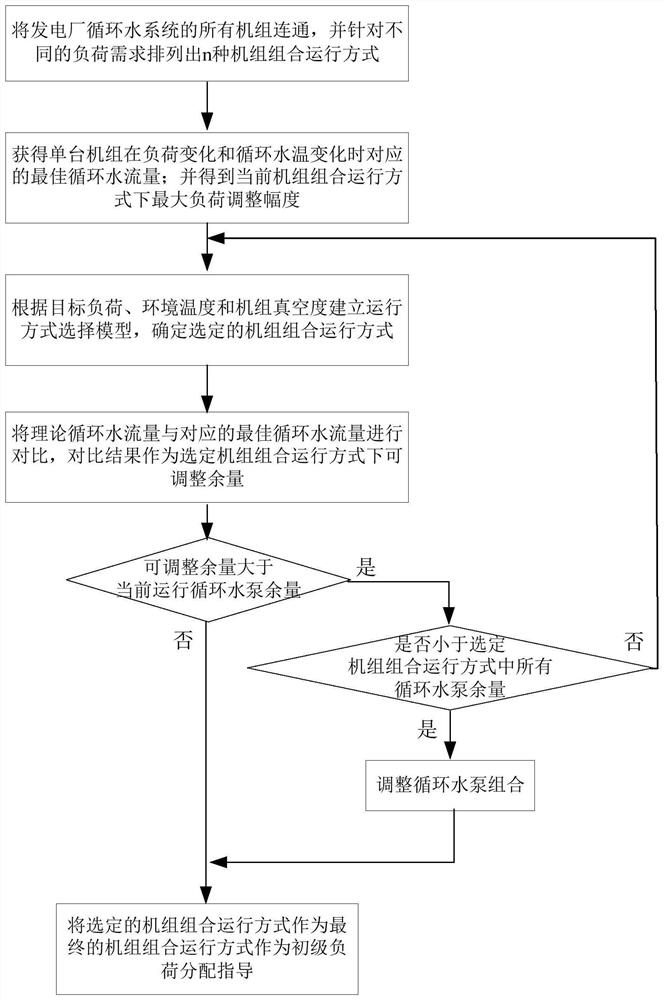

[0025] Specific implementation mode 1. Combination figure 1 As shown, the present invention provides a load distribution adjustment method based on the operating mode of the circulating water system, including:

[0026] Step 1: Connect all units in the circulating water system of the power plant, and arrange n types of unit combination operation modes according to different load demands;

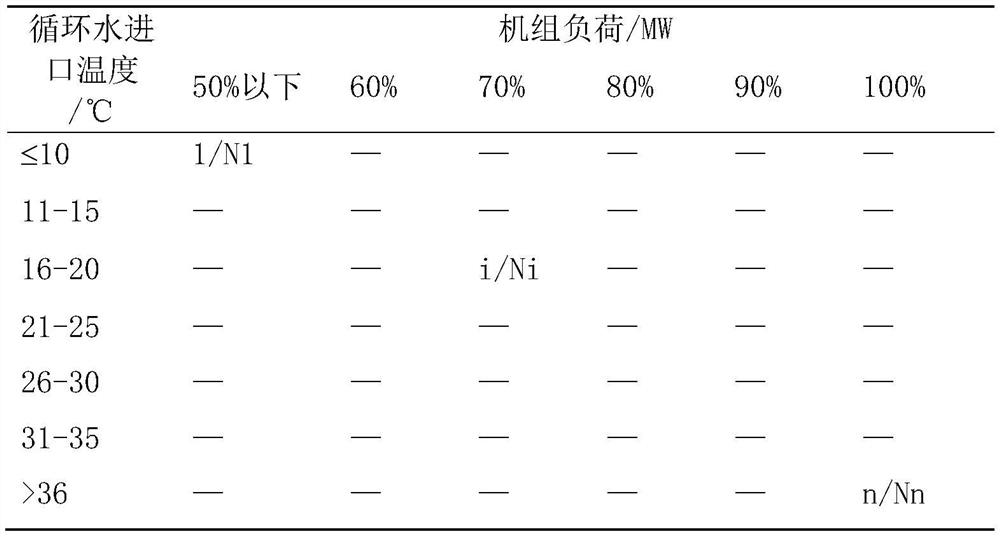

[0027] Step 2: Under each unit combination operation mode, under the condition of the best vacuum of the steam turbine, use the ergodic method to obtain the optimal circulating water flow rate corresponding to the load change and circulating water temperature change of a single unit; and obtain the current unit combination operation The maximum load adjustment range under the mode;

[0028] Step 3: Establish an operation mode selection model according to the target load, ambient temperature and vacuum degree of the unit, and determine the selected unit combination operation mode according t...

specific Embodiment

[0041] Specific examples: combining figure 2 Shown, the method of the present invention is used for the guidance of primary load adjustment between plants, and concrete process is:

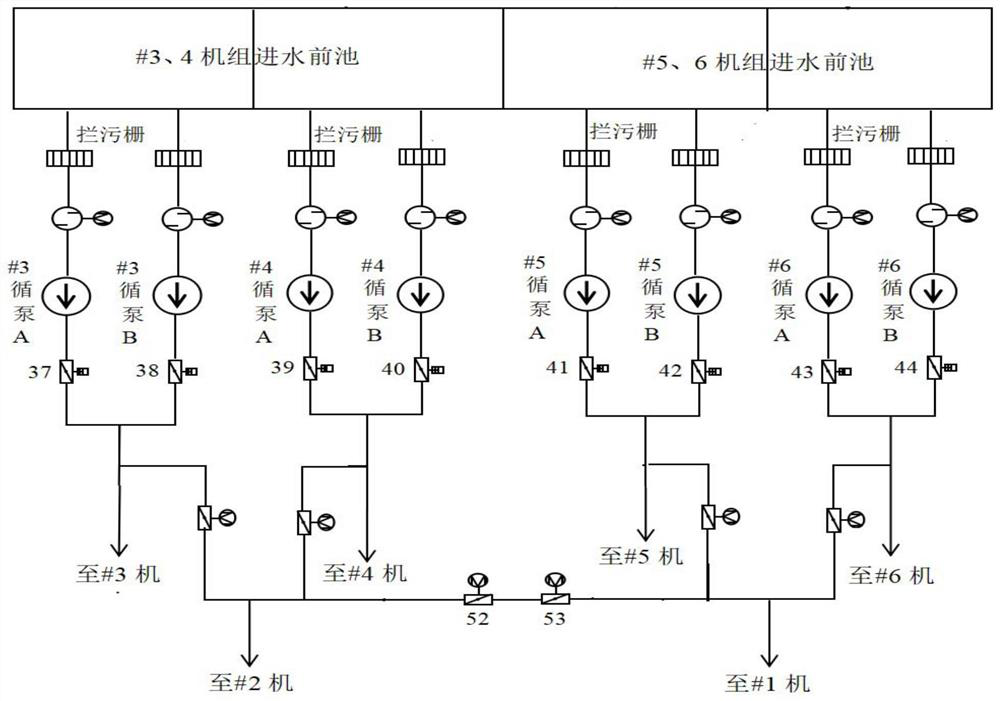

[0042] Step 1: Take a power plant as an example to carry out the renovation project of circulating water connection. The plant originally had two 300MW units and adopted an open circulating water system. Due to factors such as environmental changes and equipment aging, its operating efficiency is low. If the power plant is expanded, for example, adding 4×600MW units and carrying out the transformation of circulating water, the output of the circulating water pumps of the four newly added 600MW units can be increased and the operation will be stopped. Two 300MW units. Its renovation plan includes:

[0043] Stop using the circulation pump facilities in the first phase, and change the circulation pump room in the second phase to provide circulating cooling water to the units in the first and secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com