A track and field line drawing machine

A line drawing machine and runway technology, applied in the field of sports, can solve the problem of unable to temporarily draw track and field runways.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

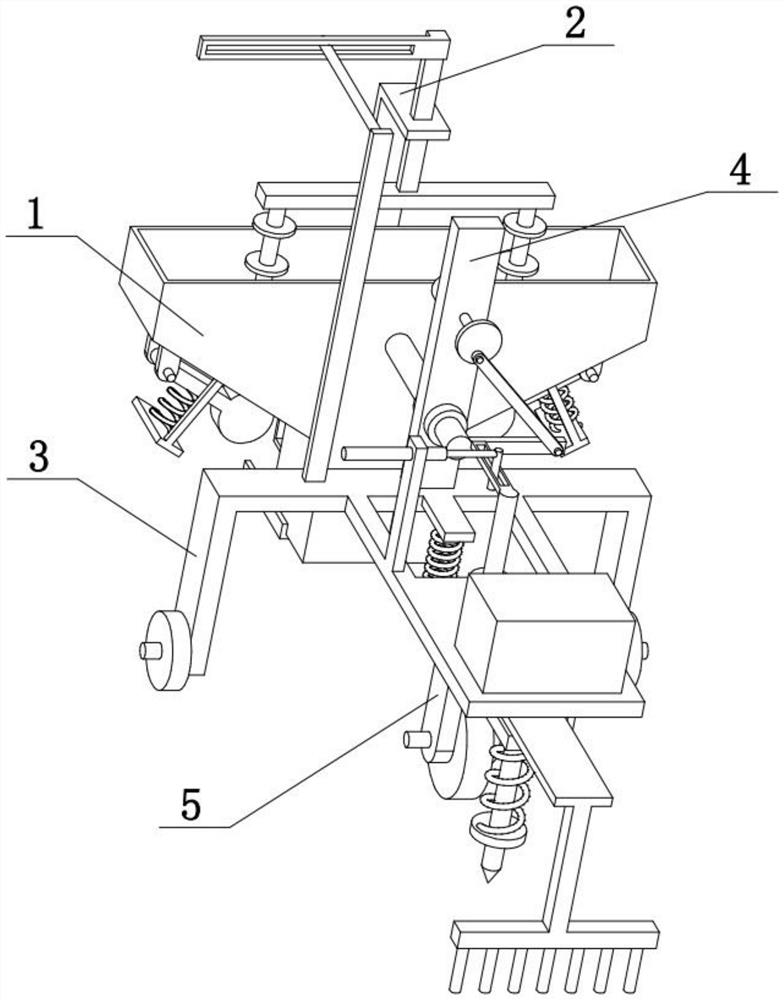

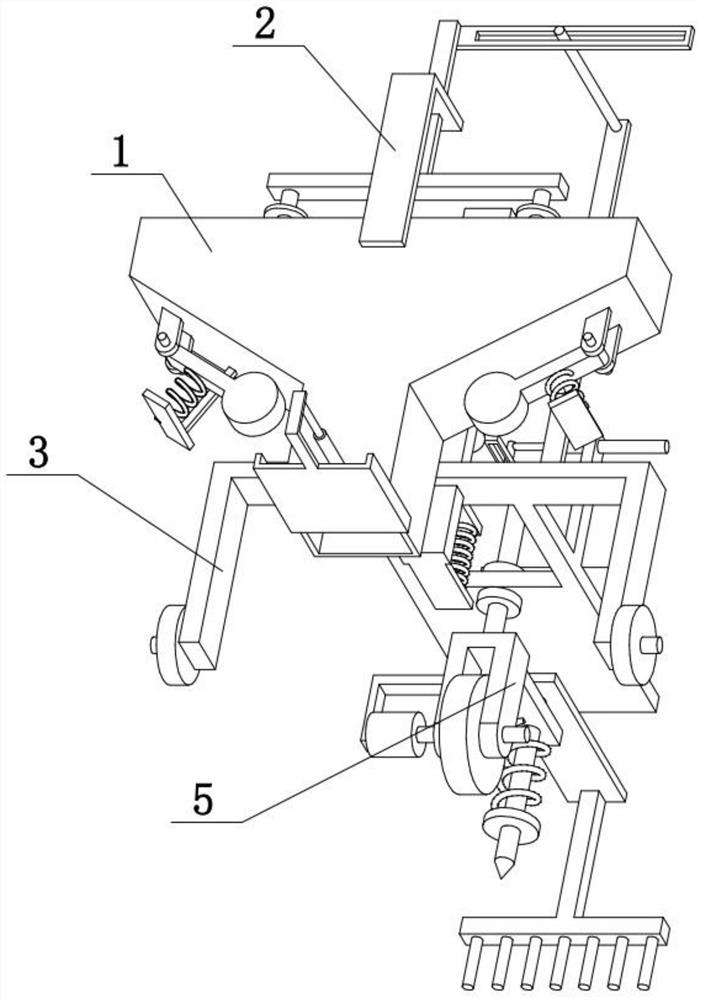

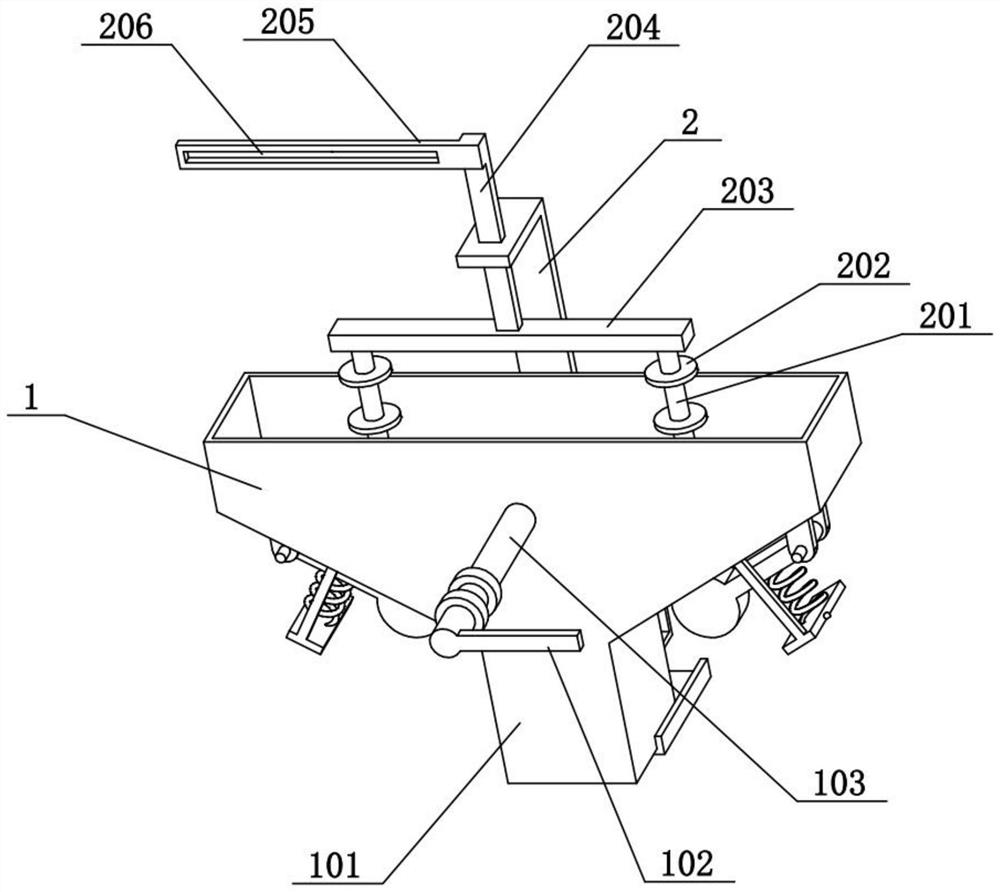

[0026] Combine below Figure 1-8 Illustrating this embodiment, the present invention relates to the field of sports, more specifically, a track and field line drawing machine, comprising a storage box 1, a discharge cylinder 101, a bottom cover 104, an oil cylinder I105, a hammer head 106, a spring frame 107 and a hammer With rod 108, the present invention can temporarily draw a track and field track.

[0027] The storage box 1 is wide at the top and narrow at the bottom, the lower part of the storage box 1 is provided with a discharge cylinder 101, the rear side of the discharge cylinder 101 is fixedly connected with an oil cylinder I105, the bottom cover 104 is slidably connected to the lower part of the discharge cylinder 101, and the oil cylinder I105 The rear end of the storage box 108 is fixedly connected to the rear of the bottom cover 104, one hammer rod 108 is provided on the left and right sides, the left and right sides of the storage box 1 are inclined surfaces, an...

specific Embodiment approach 2

[0028] Combine below Figure 1-8 Illustrating this embodiment, the track and field line drawing machine further includes an L-shaped frame 2, a vertical column 201, a wafer 202, a horizontal bar 203 and a lifting column 204. The upper part of the storage box 1 is fixedly connected with the L-shaped frame 2. The L-shaped frame 2 The upper part of the frame 2 is vertically slidably connected with a lifting column 204, the lower end of the lifting column 204 is fixedly connected with a horizontal bar 203, and the left and right ends of the lower side of the horizontal bar 203 are fixedly connected with vertical columns 201. A plurality of discs 202 are fixedly connected to the bottom, and the two vertical columns 201 are respectively located above the two storage boxes 1 . The lifting column 204 can slide vertically on the L-shaped frame 2 to drive the horizontal bar 203, the two vertical columns 201 and the plurality of wafers 202 on the two vertical columns 201 to move up and d...

specific Embodiment approach 3

[0029] Combine below Figure 1-8Illustrating this embodiment, the track and field line drawing machine further includes a circumferential rod 102, a fixed shaft 103, a rectangular column 4, a disc 401 and a hinge rod 402. The front side of the storage box 1 is fixedly connected with the fixed shaft 103, and the fixed shaft 103 Circumferential rod 102 is fixedly connected to the front end of the fixed shaft 103, and the front end of the fixed shaft 103 is rotatably connected to the middle of the rectangular column 4. The upper part of the rectangular column 4 is provided with a circular disc 401 driven by a motor, and the eccentric position of the circular disc 401 is hinged with a hinge rod 402. The lower end of the hinge rod 402 is hinged to the outer end of the circumferential rod 102 . When the disc 401 rotates, the circular rod 102 is driven to swing up and down by the hinge rod 402, which in turn drives the fixed shaft 103 to rotate in the positive and reverse direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com