Water-based paint spray booth dry-type filtering device and maintenance and replacement method thereof

A filter device and spray booth technology, applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., to achieve good effect, convenient operation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

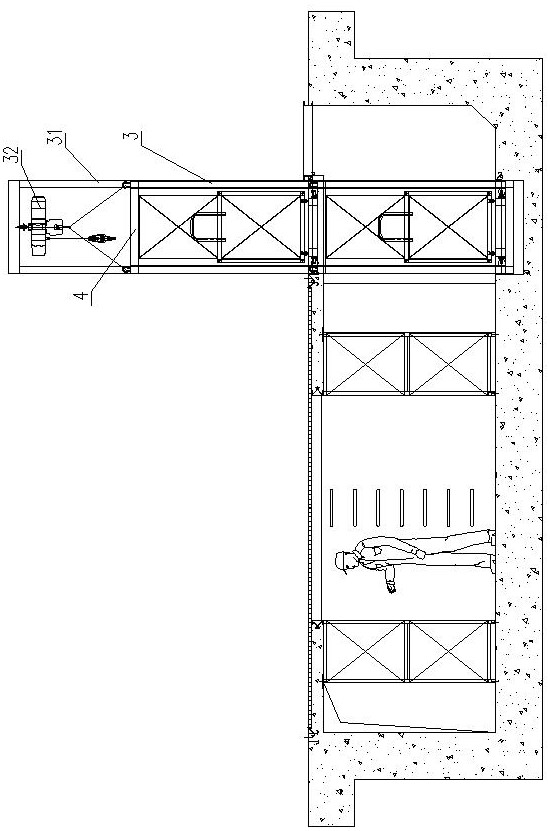

[0041] Take the famous construction machinery water-based paint spray booth as an example.

[0042] Working conditions: 288 days / year, 20 hours / day.

[0043] Workpiece parameters: 1100 sets / month about 2400 sets / month

[0044] The largest workpiece size of a single workpiece: 1485*1460*280mm

[0045] Taking the new system put into use as an example, the usage method is as follows:

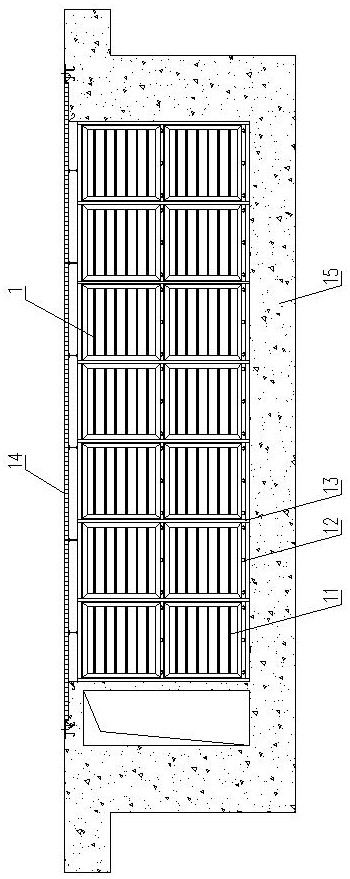

[0046] 1. In the dry carton filter system 1, the carton filter 11 has a specification of 820x665x840 and a quantity of 28. The air volume of the spray booth is 60000m3 / h, the replacement cycle is not less than 30 days, and the paint mist purification rate is greater than 98%;

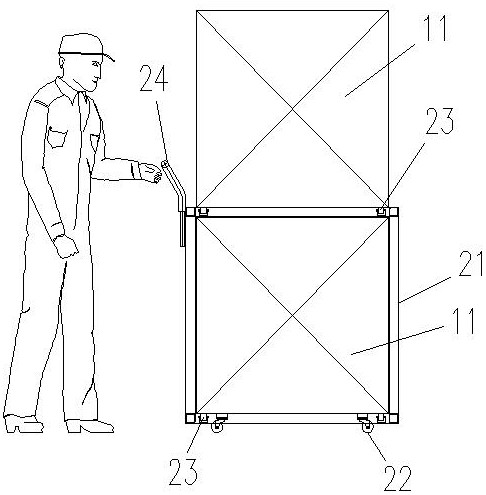

[0047] 2. When performing maintenance and replacement, follow the above operation steps. The time for each group is about 8 minutes, and all the above replacement work can be completed in 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com