Waste gas separation type treatment equipment for recycled plastic particle recovery production

A technology of recycled plastic particles and processing equipment, which is applied in the direction of dispersed particle separation, dispersed particle filtration, separation methods, etc., which can solve the problem that the filter structure cannot be fully contacted, cannot be linked to clean the residue on the filter box, and the contact effect between the exhaust gas and the filter structure is not good. Good and other problems, to achieve the effect of improving the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

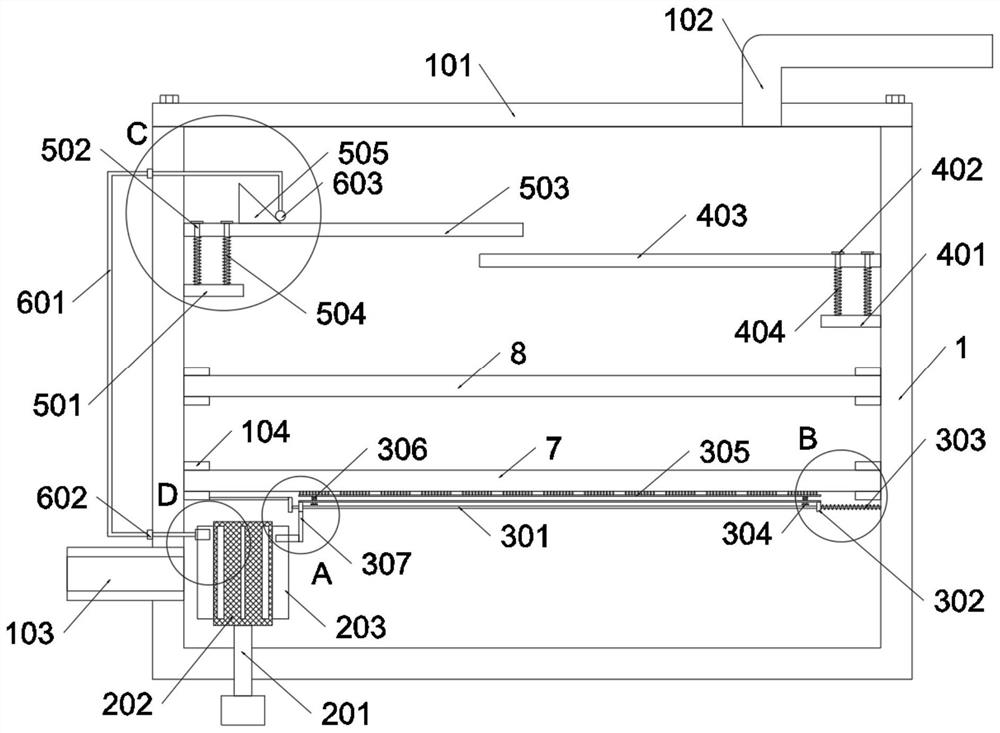

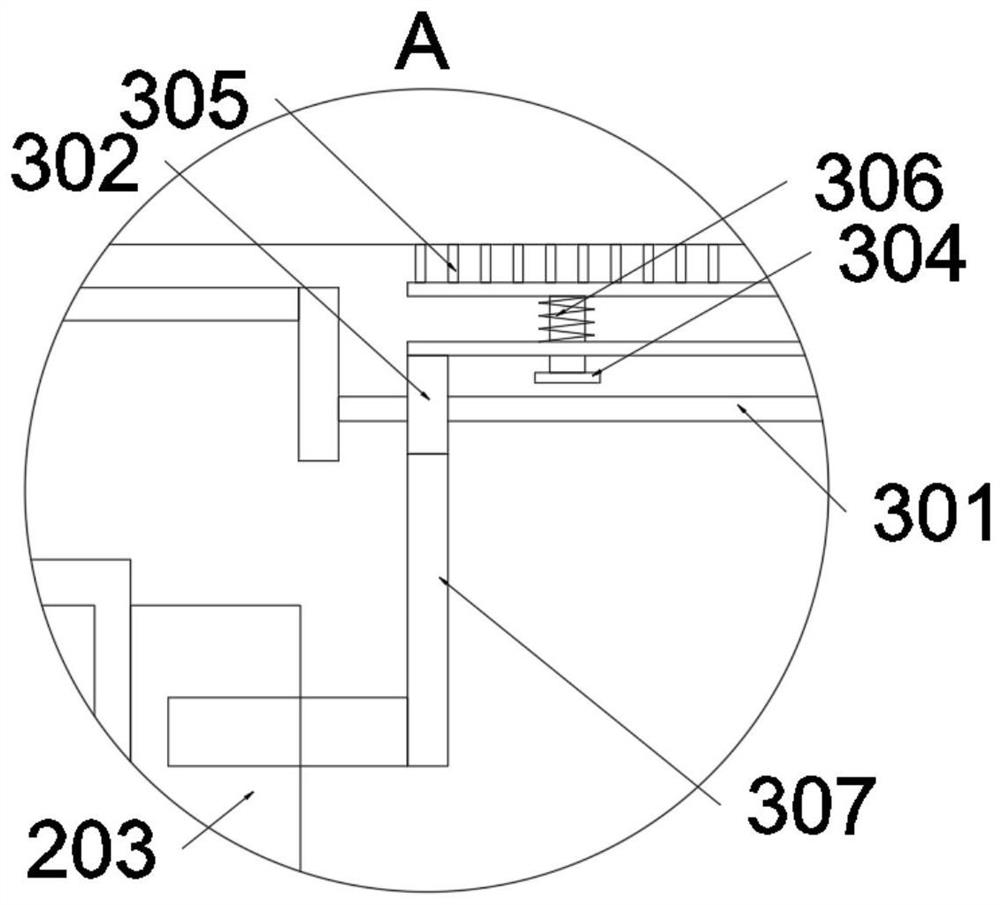

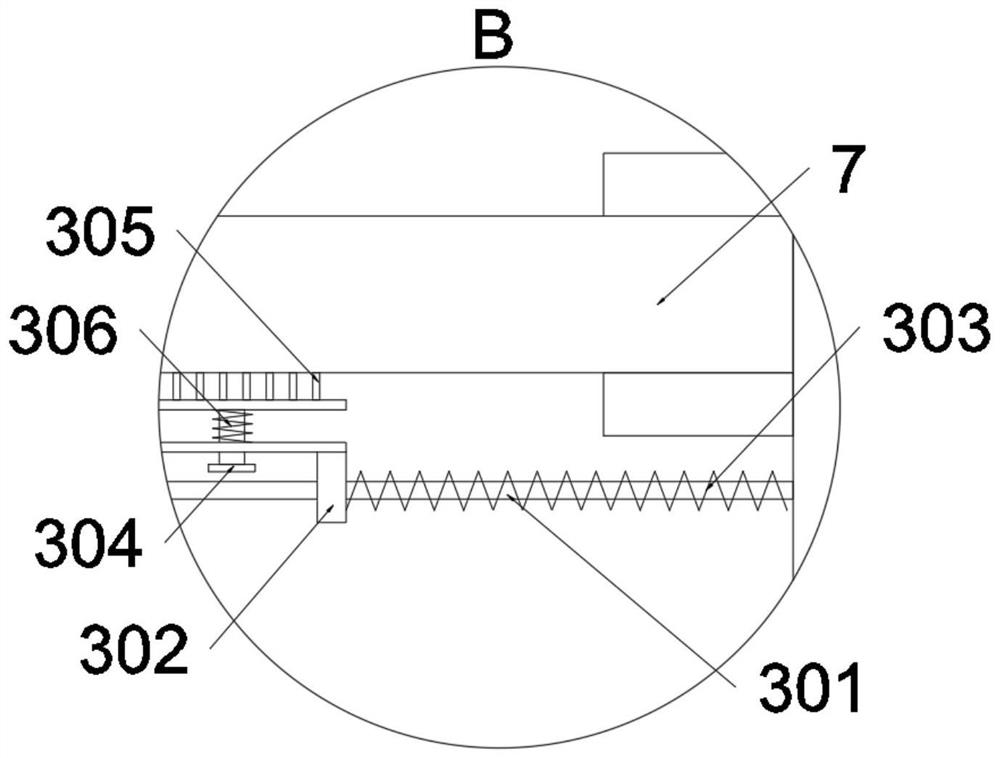

[0030] as attached figure 1 To attach Figure 8 Shown:

[0031] The present invention provides a waste gas separated processing equipment for recycled plastic particle recycling production, which includes a box body 1; a drive structure 2 is installed in the box body 1, and a cleaning structure 3 is also installed in the box body 1; the box body 1 is installed with a second A shielding structure 4 and a second shielding structure 5, and a toggle structure 6 is also installed in the box body 1; refer to as figure 1 and Figure 4, the second shielding structure 5 includes a mounting base B501, a sliding rod D502, a baffle B503 and an elastic member D504, the mounting base B501 is welded on the left end surface of the inner wall of the box body 1, and two sliding rods D502 are symmetrically welded on the top surface of the mounting base B501 , and a baffle B503 is slidably connected to the two sliding rods D502; an elastic member D504 is sleeved on the two sliding rods D502, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com