Bag type packaging machine

A packaging machine and bag-type technology, which is applied in the field of bag-type packaging machines, can solve the problems of automatic recycling of dust, etc., and achieve the effects of self-cleaning, reducing labor intensity and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

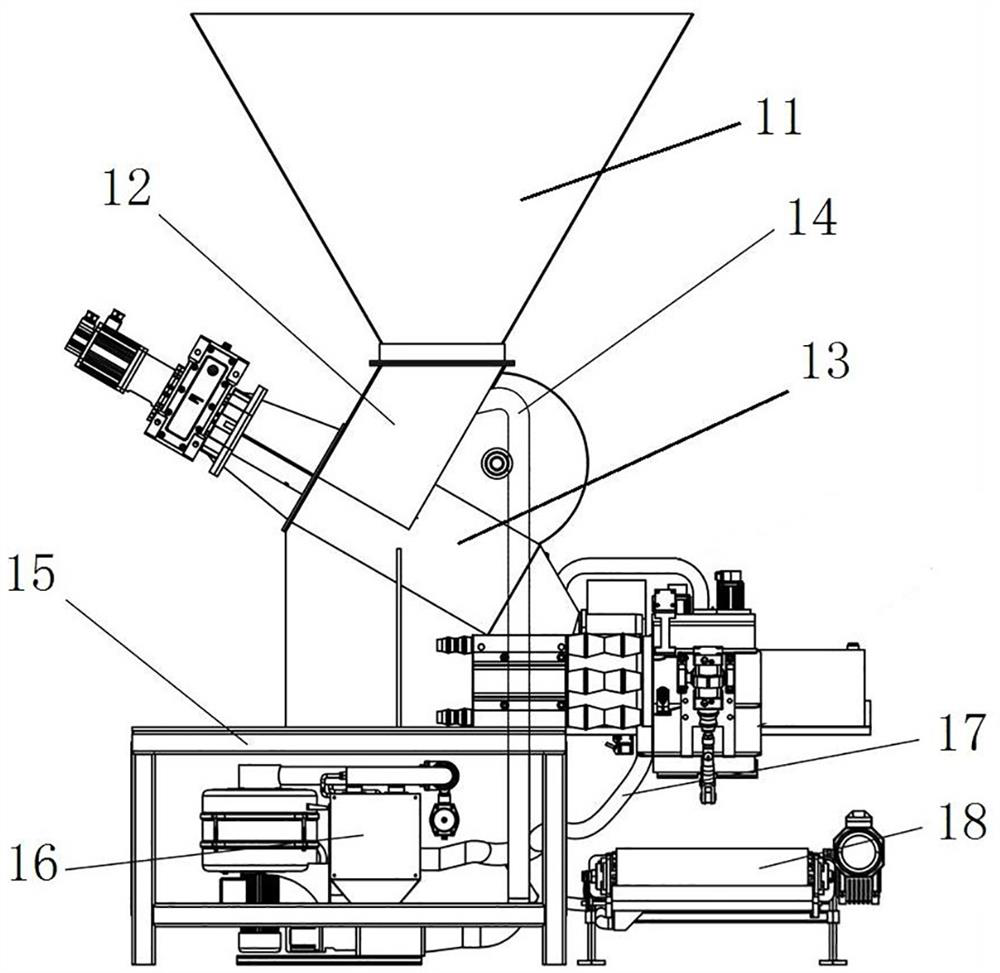

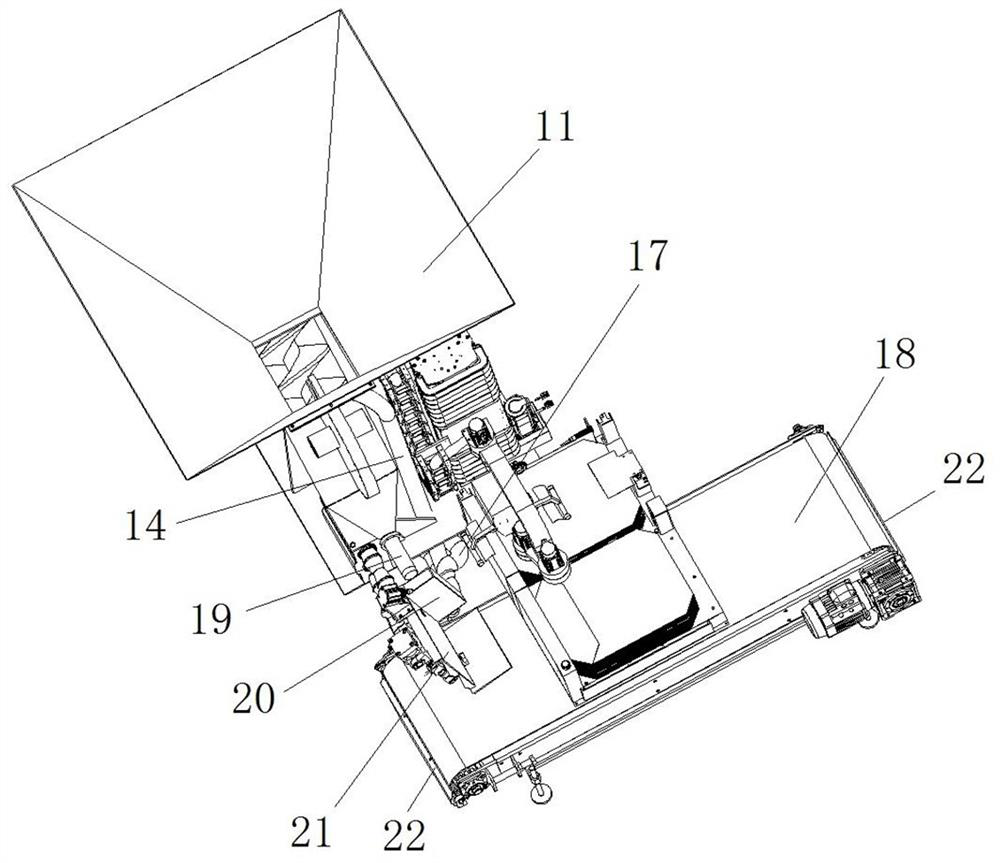

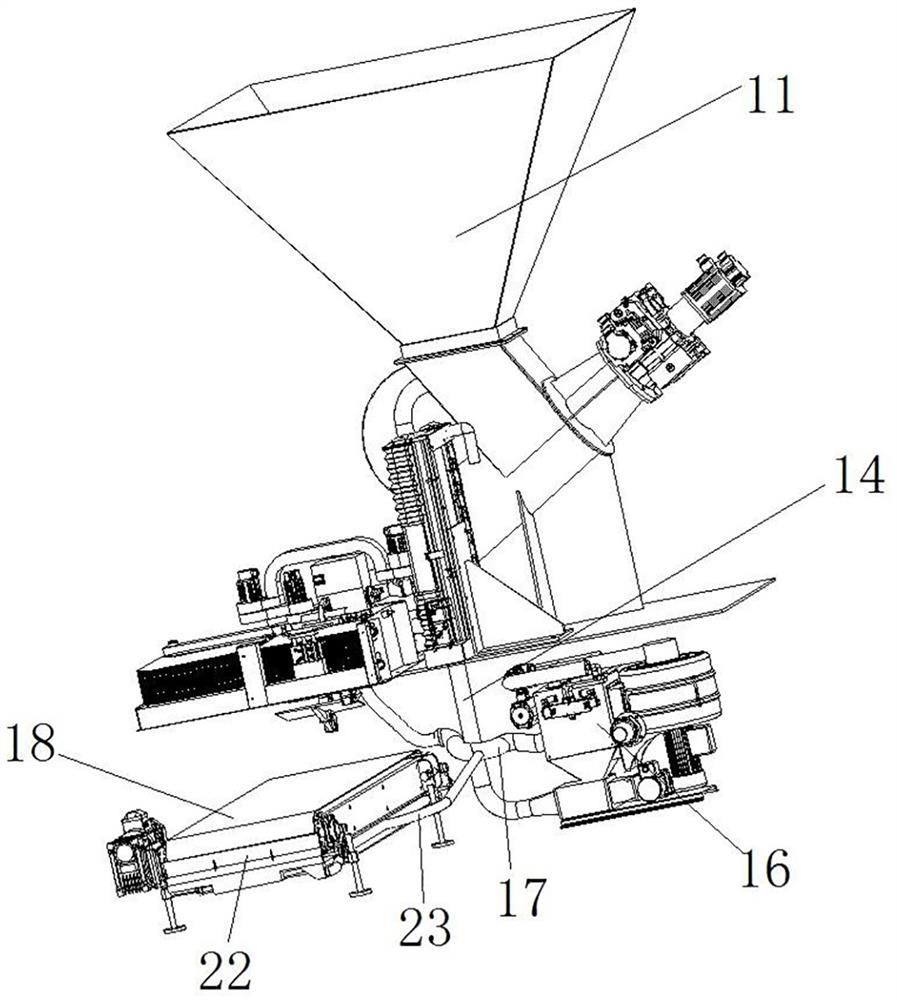

[0052] The bag packaging machine in this embodiment is a valve bag packaging machine, such as Figure 1 to Figure 4As shown, the bag packaging machine comprises a frame 15, a feed shell is provided above the frame 15, a filter cartridge dust collector 16 is provided below the frame 15, and a discharge nozzle 19 is provided at the bottom of the feed shell, and a discharge nozzle 19 is provided at the bottom of the feed shell. The powder in the shell enters the valve pocket through the discharge nozzle 19. Wherein, the valve bag constitutes a material bag. In other embodiments, the pocket is an open-mouth bag.

[0053] In this embodiment, the feeding shell includes a hopper 11, a feeding barrel 12, and a feeding barrel 13 arranged sequentially from top to bottom. the end. When working, the powder enters the feeding barrel 12 through the hopper 11, and enters the feeding barrel 13 through the feeding barrel 12. Under the action of the feeder, the powder is transported to the d...

Embodiment 2

[0073] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the end of the twin-screw near the outlet 44 of the dust conveying case is suspended. In this embodiment, a support plate is provided at the end of the twin-screw close to the outlet of the dust-conveying case in the dust-conveying case. The support plate extends along the arrangement direction of the twin-screws. The ends of the twin-screws are rotated and assembled on the support plate. , the width of the support plate is as small as possible.

Embodiment 3

[0075] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the discharge nozzle gas collection case 20 is fixed on the filling seat 21, and the air inlet pipe 17 communicates with the discharge nozzle gas collection case 20, so as to facilitate the filling with powder. The air enters in the dust removal case 35. In this embodiment, the filling seat is not provided with a discharge nozzle gas collecting shell, and the end of the air inlet pipe close to the discharge nozzle is a flared structure, and this end is fixed on the filling seat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com