Air exhaust device for starch packaging machine

A technology of air extraction device and packaging machine, which is applied in the direction of pressurized/gasification packaging, etc., which can solve the problems of affecting the product warranty period, insufficient net weight of materials, troublesome storage of materials, etc., and achieve good economic benefits and environmental protection effects. It is not easy The effect of loose stacking and stacking is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner.

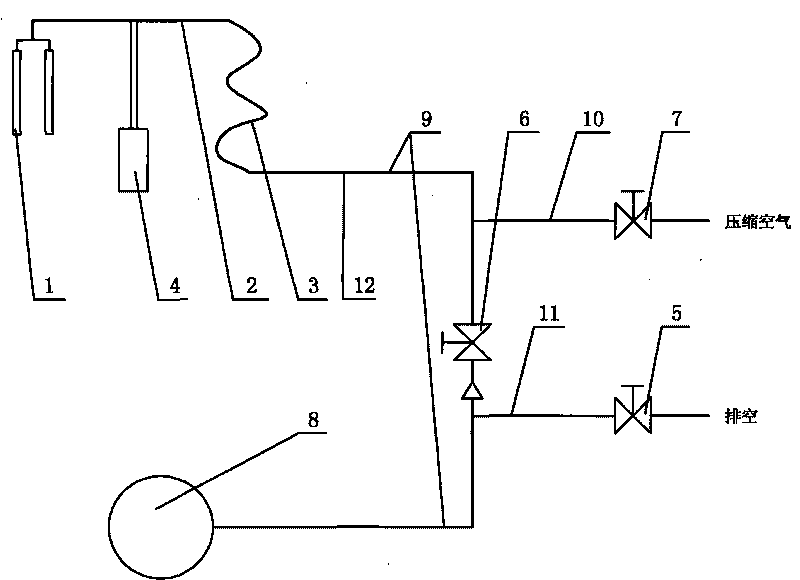

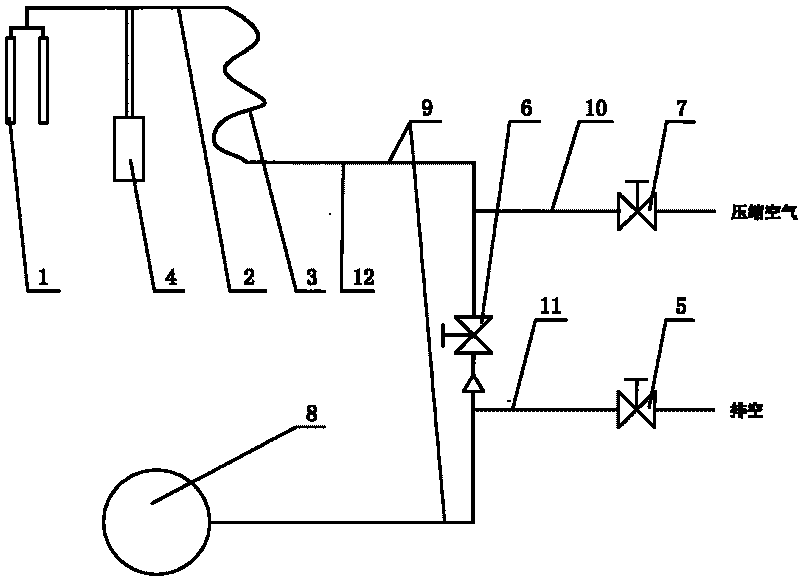

[0014] Such as figure 1 As shown, the present invention is an air extraction device for a starch packaging machine, which includes a filter element 1, the filter element 1 adopts ultra-high molecular polyethylene as the main raw material, and is sintered at high temperature and high pressure. The filter element does not use any adhesive and has no medium shedding phenomenon. , The material complies with GMP / FDA requirements. The filter element 1 is connected with the lifting mechanism, and the inner cavity of the filter element 1 is connected with the vacuum extraction device through the main pipeline 10 , and the valve 6 is arranged on the main pipeline 10 . A branch pipeline 10 connected with compressed air and an empty secondary branch pipeline 11 are arranged on the main pipeline 10 , and valves are arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com