Paint spraying device for new energy automobile charging pile production

A technology for new energy vehicles and charging piles, which is applied in the field of sheet metal processing and can solve the problems of clamping and clamping difficult sheet metal parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

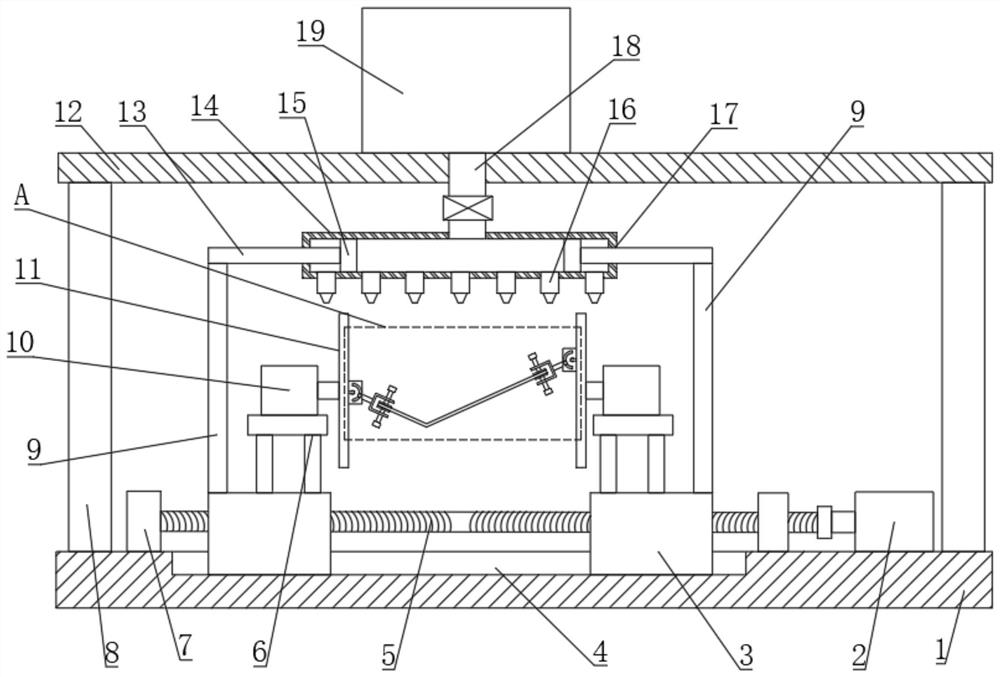

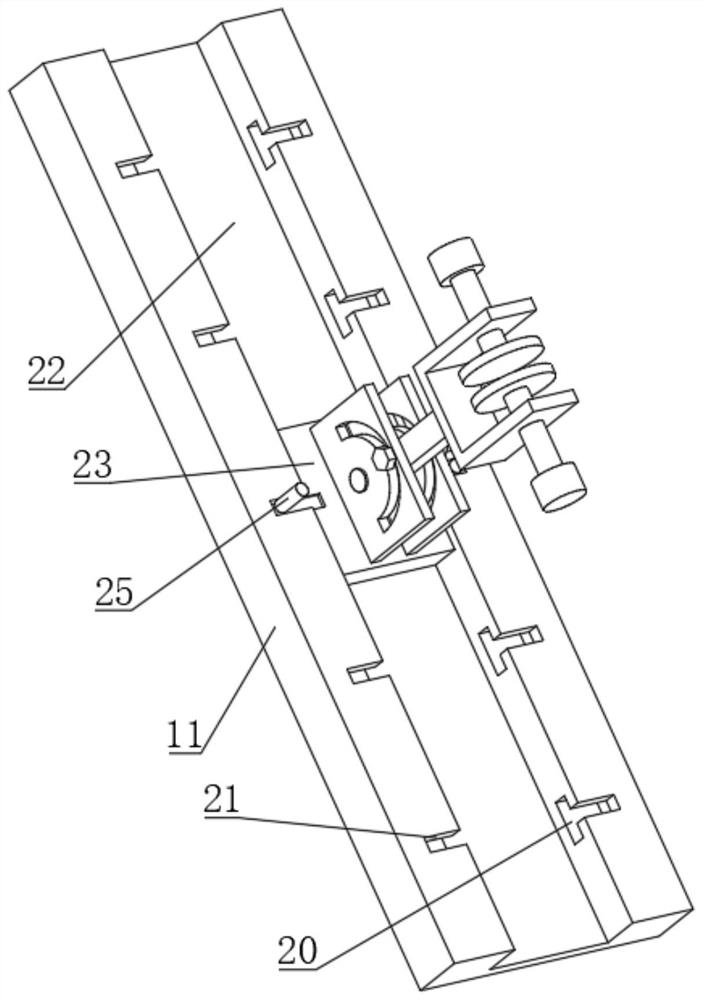

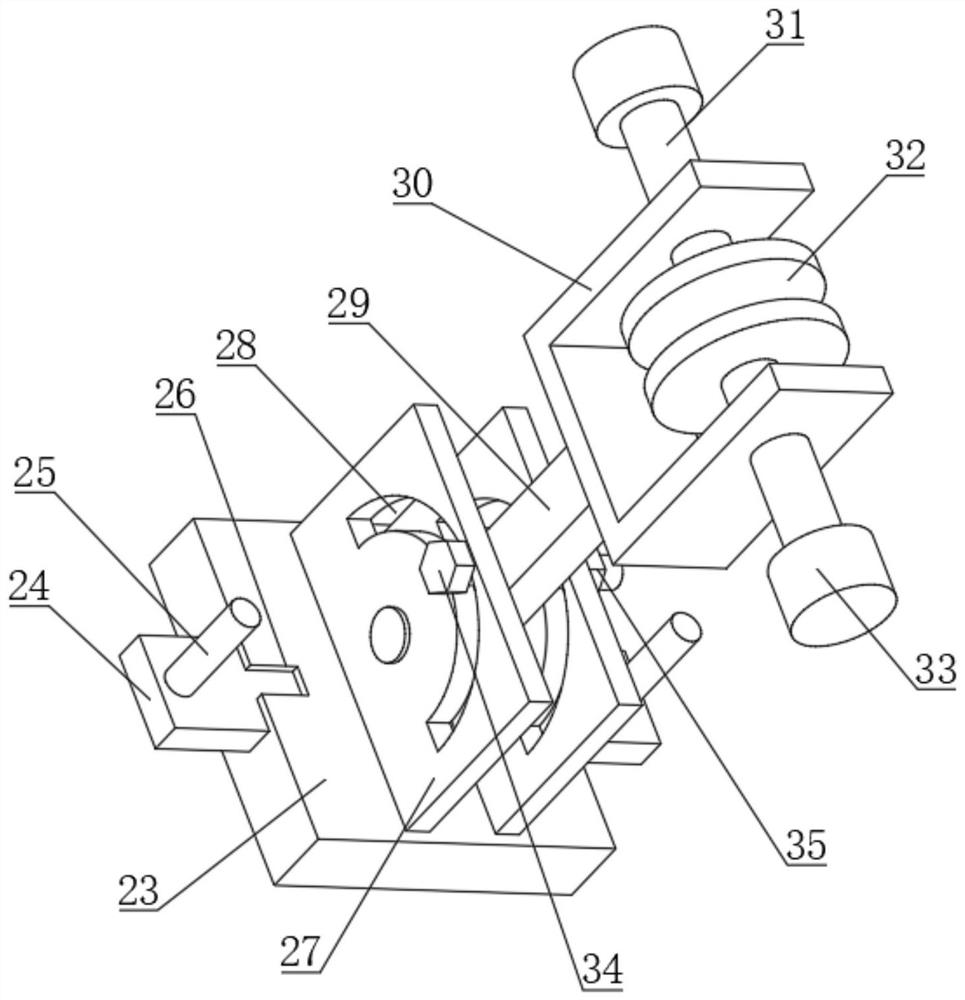

[0026] see Figure 1 to Figure 5 , a painting device for the production of new energy vehicle charging piles, comprising a base 1 and a top plate 12, the base 1 is equipped with a motor 2, the upper surface of the base 1 is provided with a chute 4, and the chute 4 is slidably connected with Two moving seats 3, the moving seat 3 is provided with a threaded through hole 1, the threaded through hole 1 is connected with a threaded shaft 5, the threaded shaft 5 is connected with the output shaft of the motor one 2, and the moving seat 3 is equipped with a motor two 10 , the output shaft of the motor two 10 is connected with a rotating plate 11, the rotating plate 11 is provided with a groove one 22, and several grooves two 20 are arranged on the left and right sides of the groove one 22, and the top of the groove two 20 Rectangular through groove one 21 is arranged on the surface, in the groove one 22 sliding fit is connected with moving plate 23, and the left and right side of mov...

Embodiment 2

[0031] see Figure 1 to Figure 5 , this embodiment is a further description of the painting device for the production of a new energy vehicle charging pile described in specific example 1. In this embodiment, two pistons 15 are arranged inside the shunt pipe 14, and two pistons 15 are arranged on the piston 15. Fixedly connected with a piston rod 13, the left end surface and the right end surface of the shunt pipe 14 are all provided with a through hole 17, the piston rod 13 runs through the through hole 17, and the side of the piston rod 13 slides with the inner wall of the through hole 17 Mate connection.

[0032] The upper surface of the moving base 3 is fixedly connected with a support column 9, and the upper end of the support column 9 is fixedly connected with the piston rod 13. The number of the piston 15, the piston rod 13 and the support column 9 are two and are all about the shunt tube. The symmetry plane of 14 is symmetrically arranged left and right, and the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com