Surface cleaning equipment for new energy automobile processing

A new energy vehicle, surface cleaning technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems that the distance between two fixtures cannot be changed, and the cleaning of parts of different sizes cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

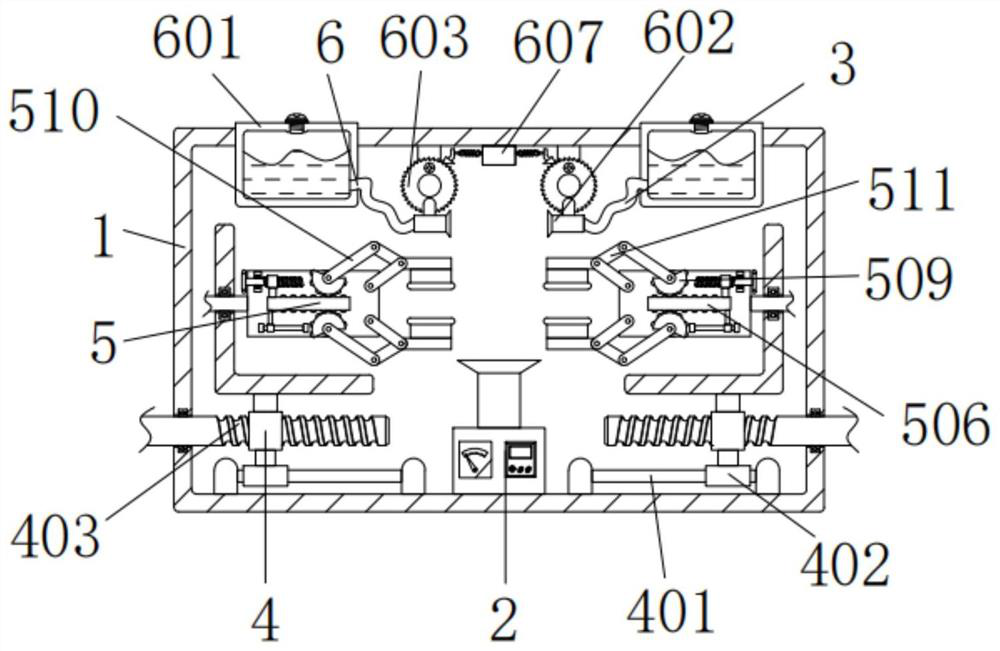

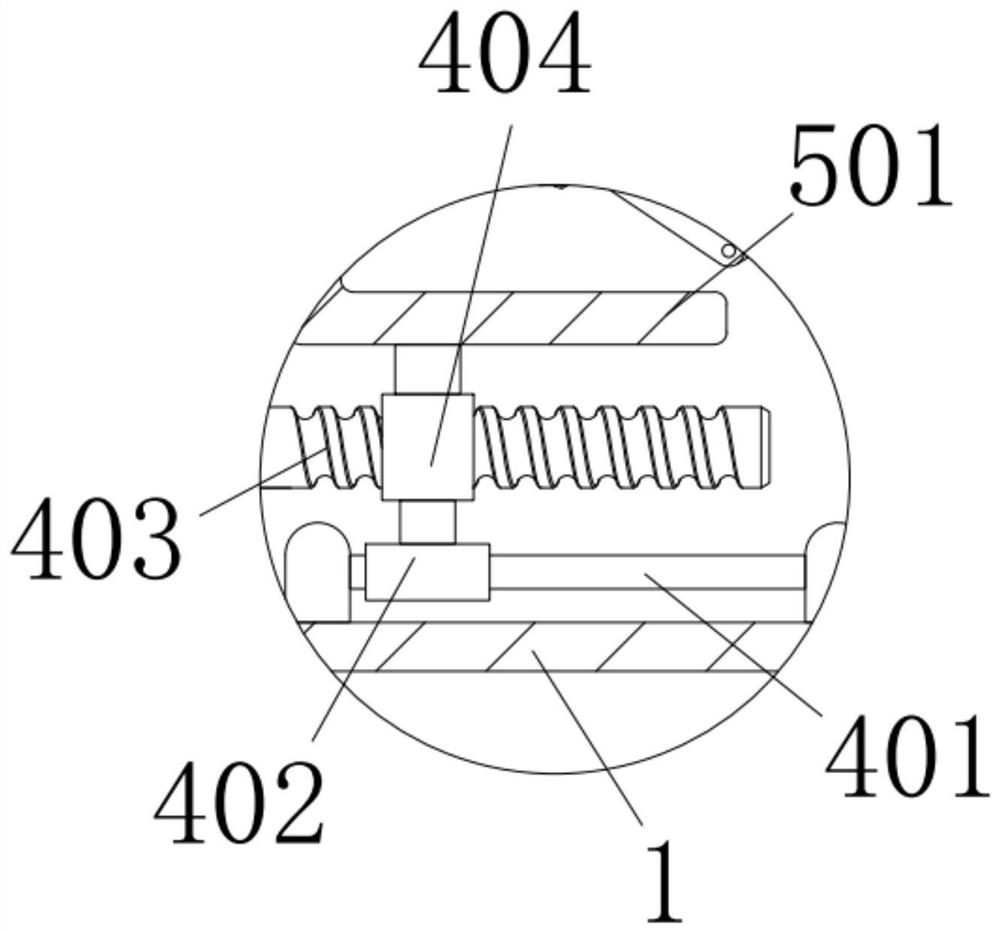

[0032] A surface cleaning device for new energy automobile processing, including a shell 1 and a hot air blower 2, the model of the hot air blower 2 is HAG-HP3A-21, the hot air blower 2 dries the cleaned parts, and the inner wall of the shell 1 is set There is a hot air blower 2, the bottom of the hot air blower 2 is fixedly connected with the bottom of the inner wall of the casing 1, and the left and right sides of the inside of the casing 1 are provided with a moving device 4, and the moving device 4 includes a first slide rail 401 and a first sliding sleeve 402 , the first screw rod 403 and the first sleeve 404, the bottom of the first slide rail 401 is fixedly connected with the bottom of the inner wall of the housing 1, the outer wall of the first slide rail 401 is provided with a first sliding sleeve 402, the first sliding sleeve 402 The inner wall is slidingly engaged with the outer wall of the first slide rail 401, the first sliding sleeve 402 can move on the outer wall...

Embodiment 2

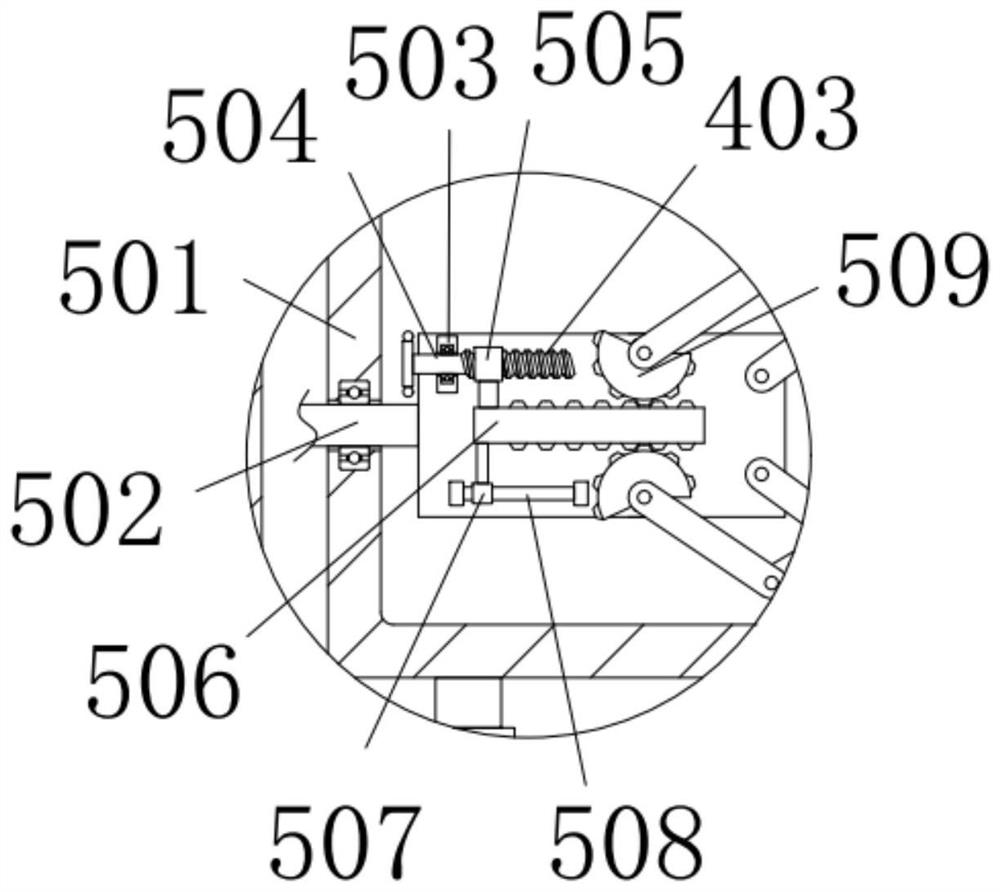

[0034] As an option, see figure 1 , 3And 4, the surface cleaning equipment for new energy automobile processing, the interior of the housing 1 is provided with two fixing devices 5, the fixing device 5 includes a housing 501, a square plate 502, a thin plate 503, a second screw 504, a second sleeve 505, Rack 506, second sliding sleeve 507, second slide bar 508, gear 509, inclined plate 510, curved plate 511 and inclined bar 512, the bottom of shell 501 is fixedly connected with the top of first sleeve 404, the left side of shell 501 The upper side is connected to the left side of the outer wall of the square plate 502 through bearings, the housing 501 can rotate through the bearings, the upper side of the square plate 502 is fixedly connected with the back side of the thin plate 503, and the inner wall of the thin plate 503 rotates with the outer wall of the second screw rod 504 through the bearing. The right side of the outer wall of the second screw rod 504 is threadedly co...

Embodiment 3

[0037] As an option, see figure 1 , 5 And 6, surface cleaning equipment for new energy vehicle processing, the inside of the housing 1 is provided with two flushing devices 6, the flushing device 6 includes a water tank 601, a water gun 602, a ratchet 603, a wide plate 604, a pawl 605, a spring 606 and a thick The plate 607, the outer wall of the water tank 601 is fixedly connected with the top of the housing 1, and the right side of the water tank 601 is fixedly connected with a water gun 602 through a hose 3. The model of the water gun 602 is determined according to the user's needs. The front side of the ratchet wheel 603 is fixedly connected, the back side of the ratchet wheel 603 is connected with a wide plate 604 through the rotation of the pin shaft, the top of the wide plate 604 is fixedly connected with the top of the inner wall of the housing 1, and the right side of the ratchet wheel 603 is unidirectionally connected with a pawl 605, the pawl 605 can fix the ratche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com