Coil conveying trolley comprehensively using laser range finder and encoder

A technology of laser range finder and rolling trolley, which is applied in the directions of instruments, motor vehicles, transportation and packaging, etc., can solve the problems of inaccurate measurement position, inability to guarantee the safety of rolling, and inaccurate positioning, so as to ensure the continuity of the products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

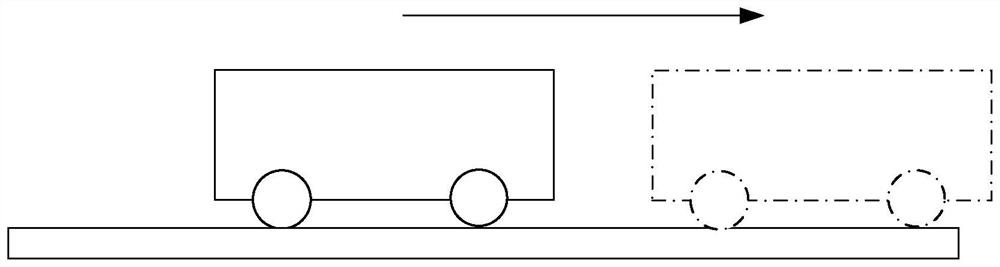

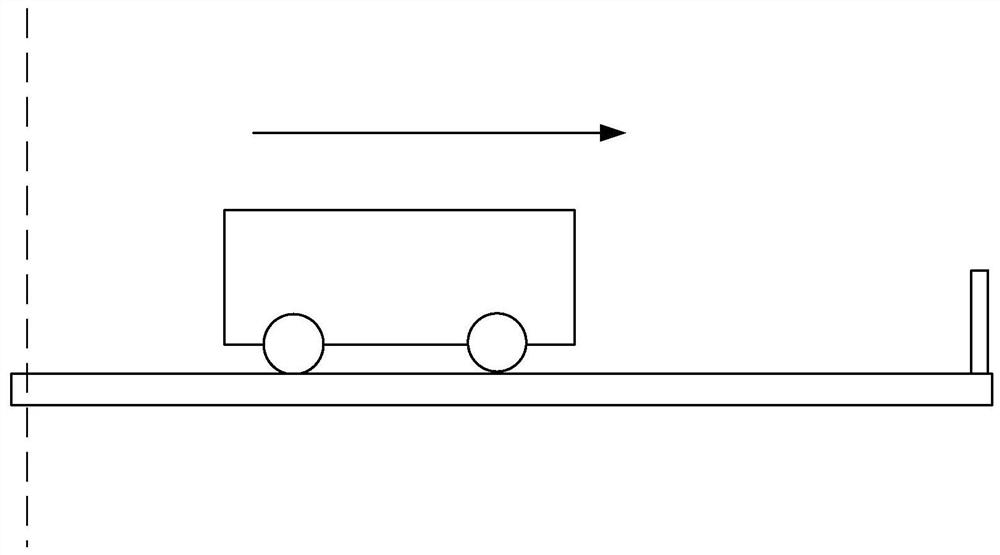

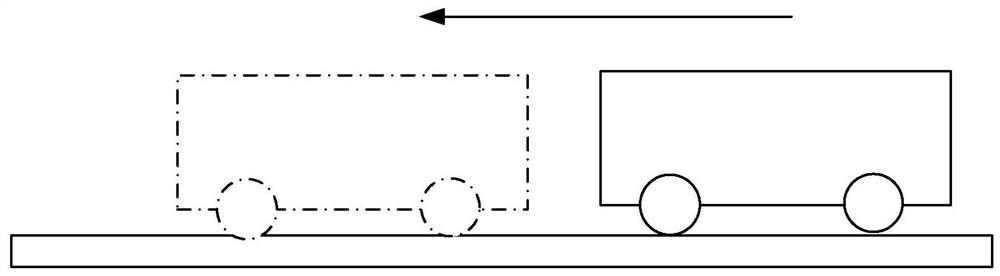

[0032] The present invention aims to comprehensively use the encoder and the laser range finder to detect the rolling process, use the programming method to overcome the respective advantages and disadvantages of the encoder and the laser range finder, and switch to the laser range finder in time when the encoder is detected to be inaccurate When the laser range finder is detected to be inaccurate, it will switch to the encoder for position tracking in time.

[0033] The specific method is as follows:

[0034] Since the principles of the laser rangefinder and the encoder are different when measuring the position, the position tracking error caused by it is also different, and different judgment methods need to be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com