Patents

Literature

91 results about "Laser velocimetry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser Doppler velocimetry (LDV), also known as laser Doppler anemometry (LDA), is the technique of using the Doppler shift in a laser beam to measure the velocity in transparent or semi-transparent fluid flows, or the linear or vibratory motion of opaque, reflecting, surfaces.

Optical imaging of blood circulation velocities

InactiveUS7113817B1Reduce the impactImprove accuracyTesting eggsDiagnostics using lightDigital imagingDetector array

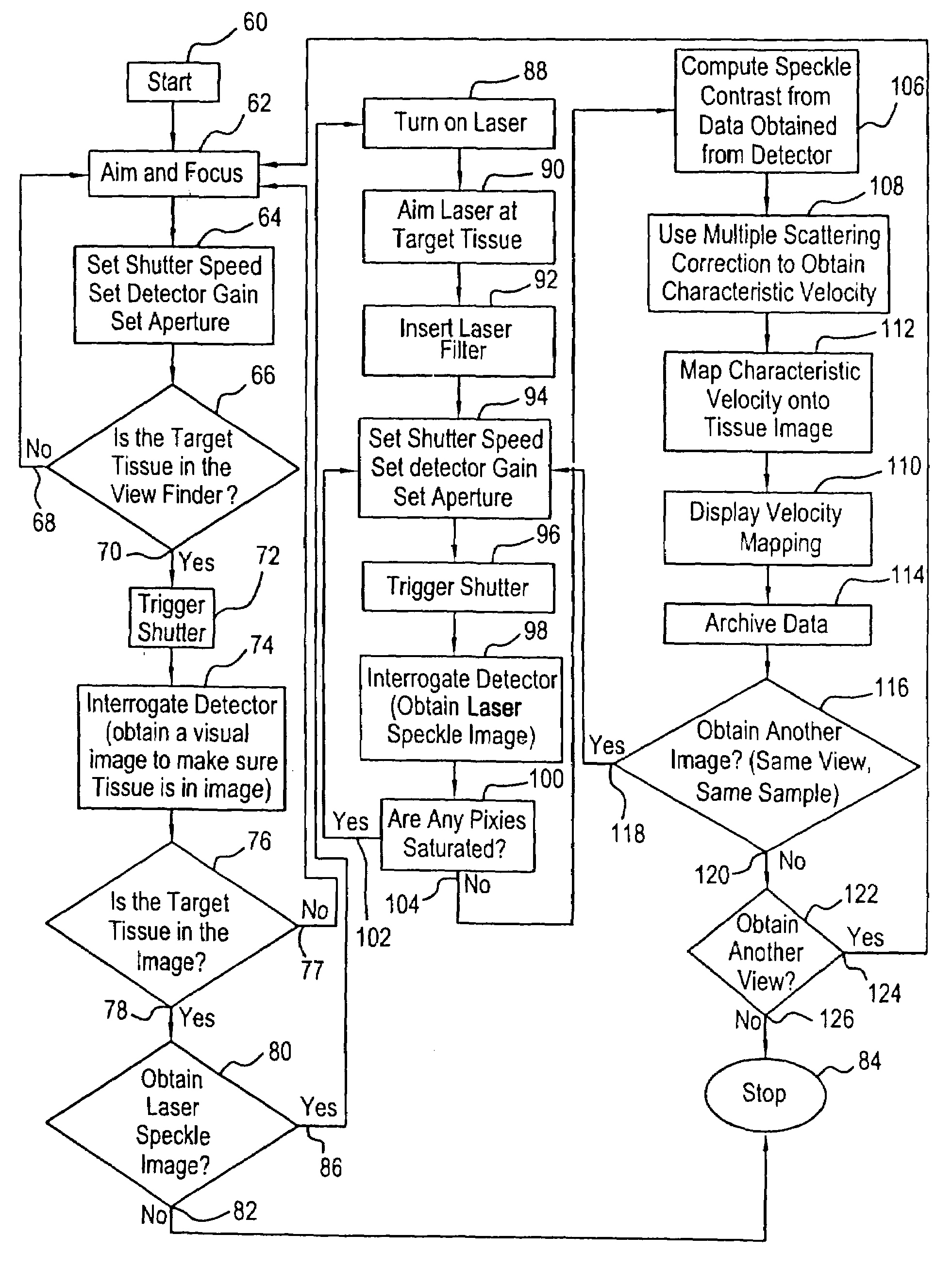

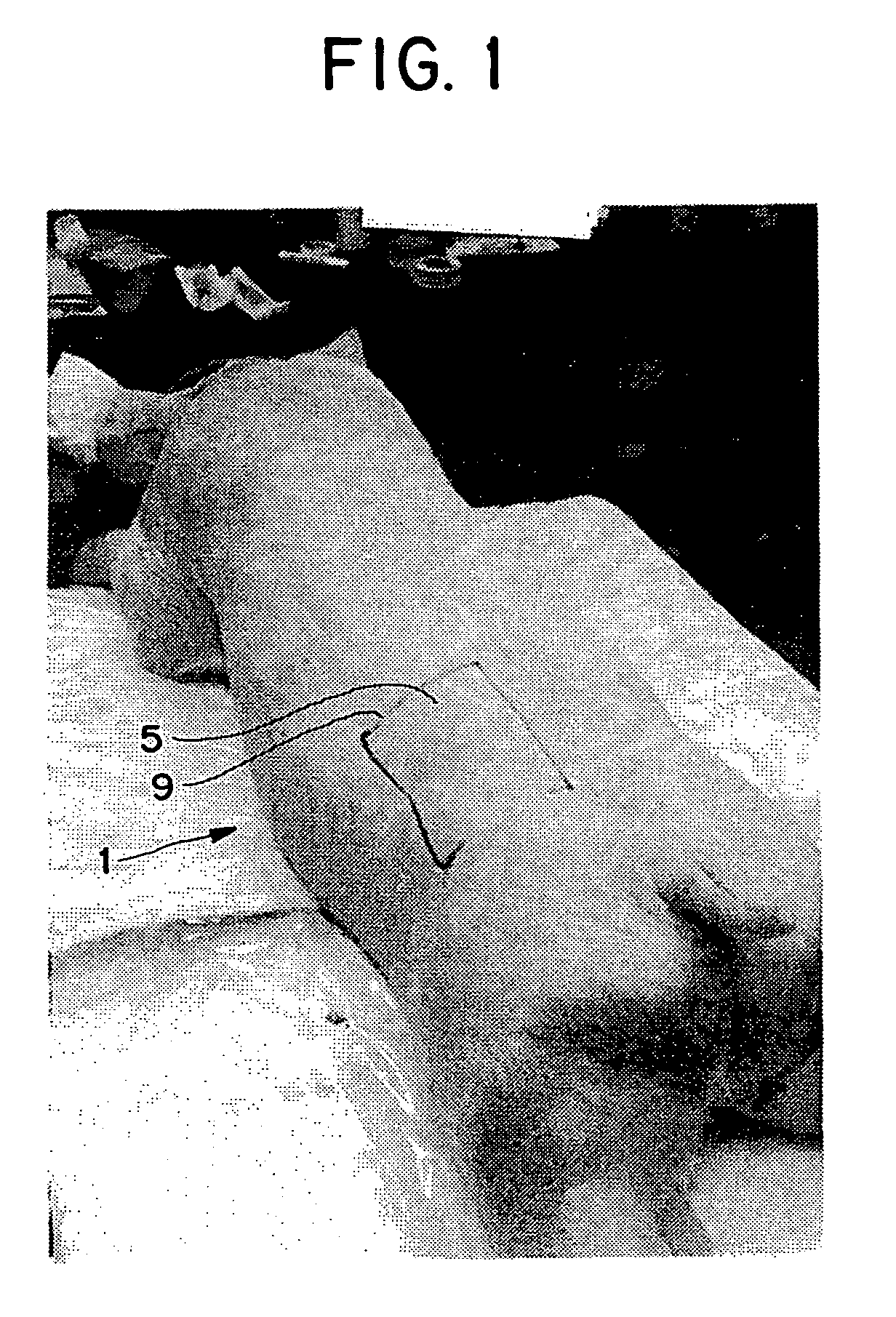

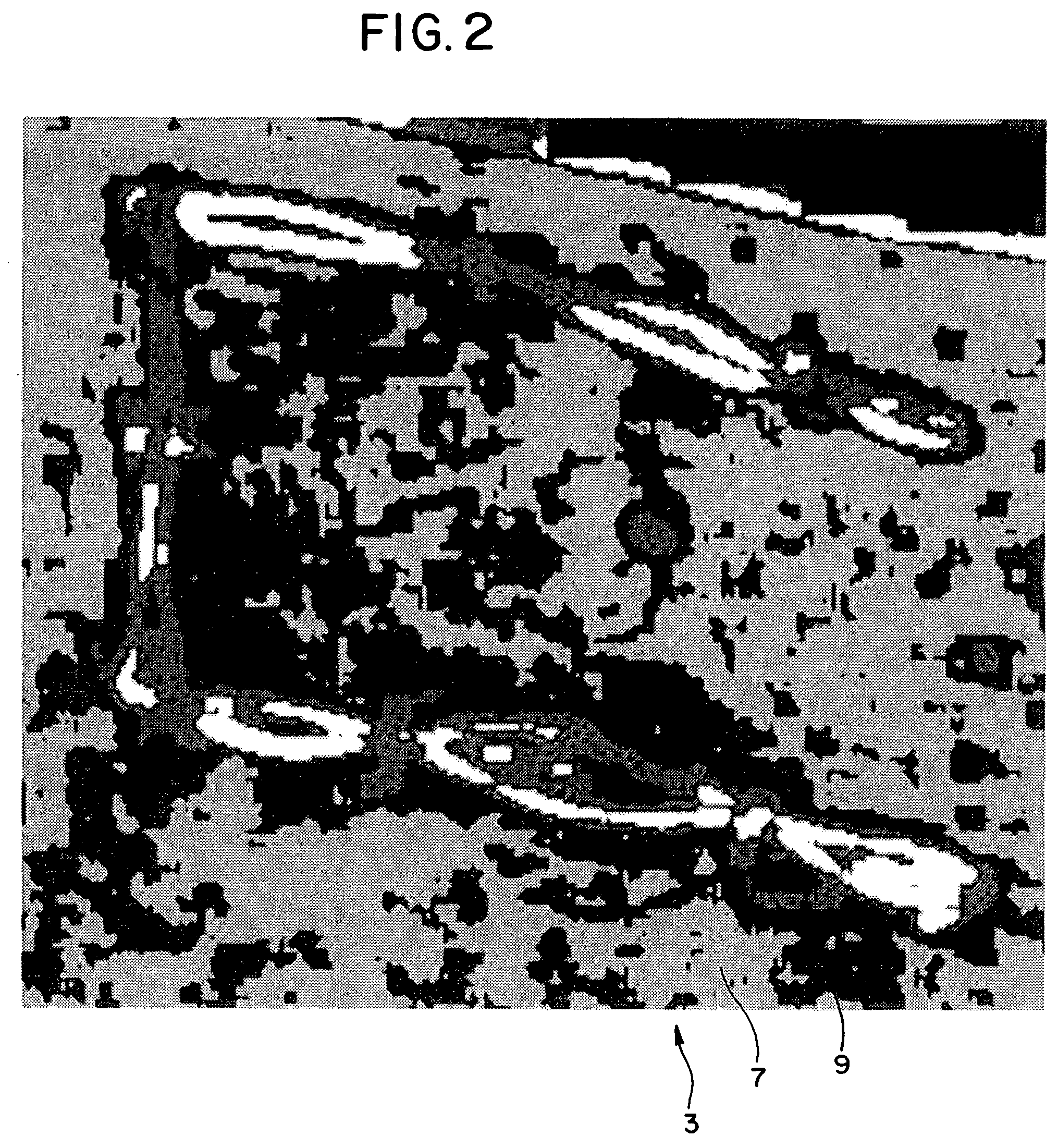

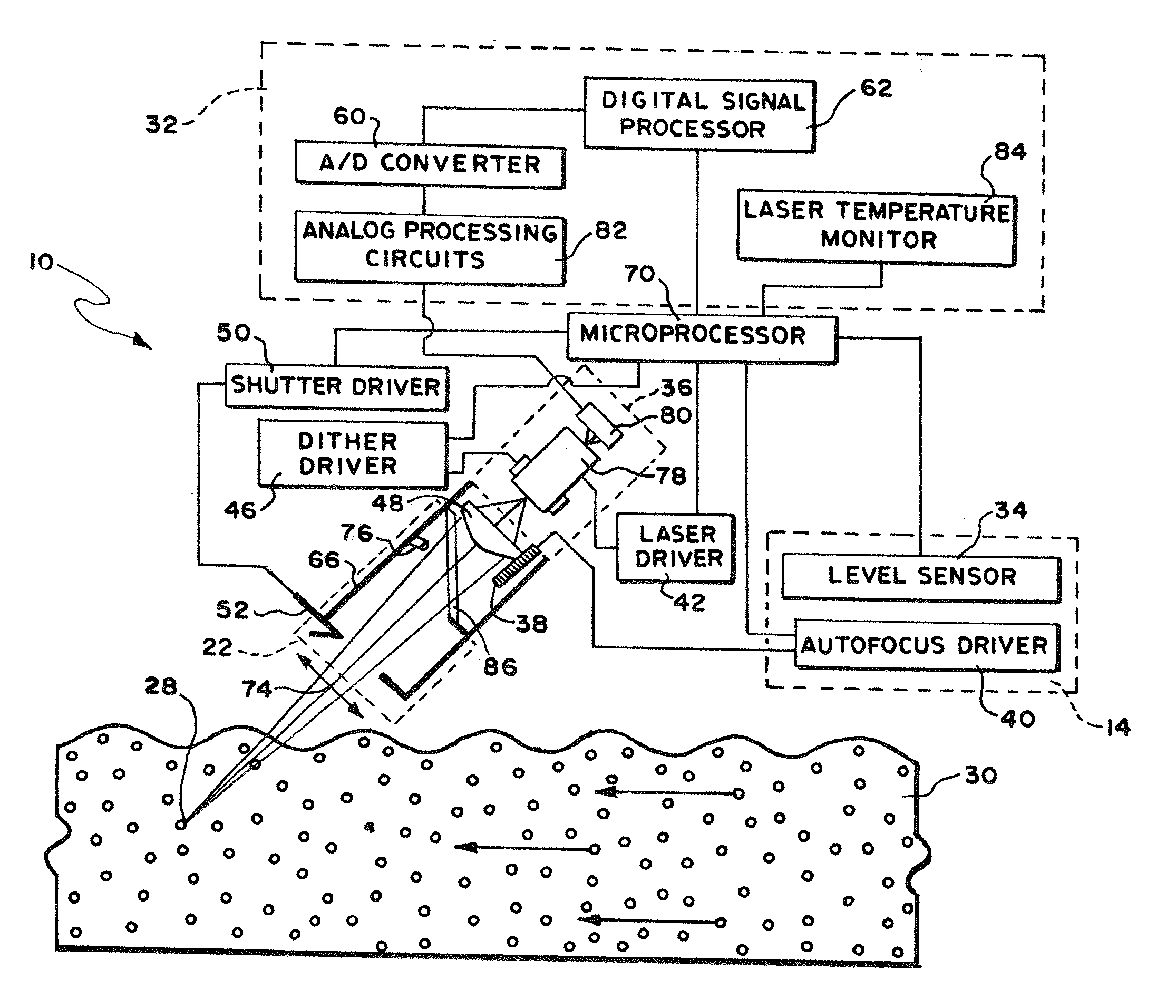

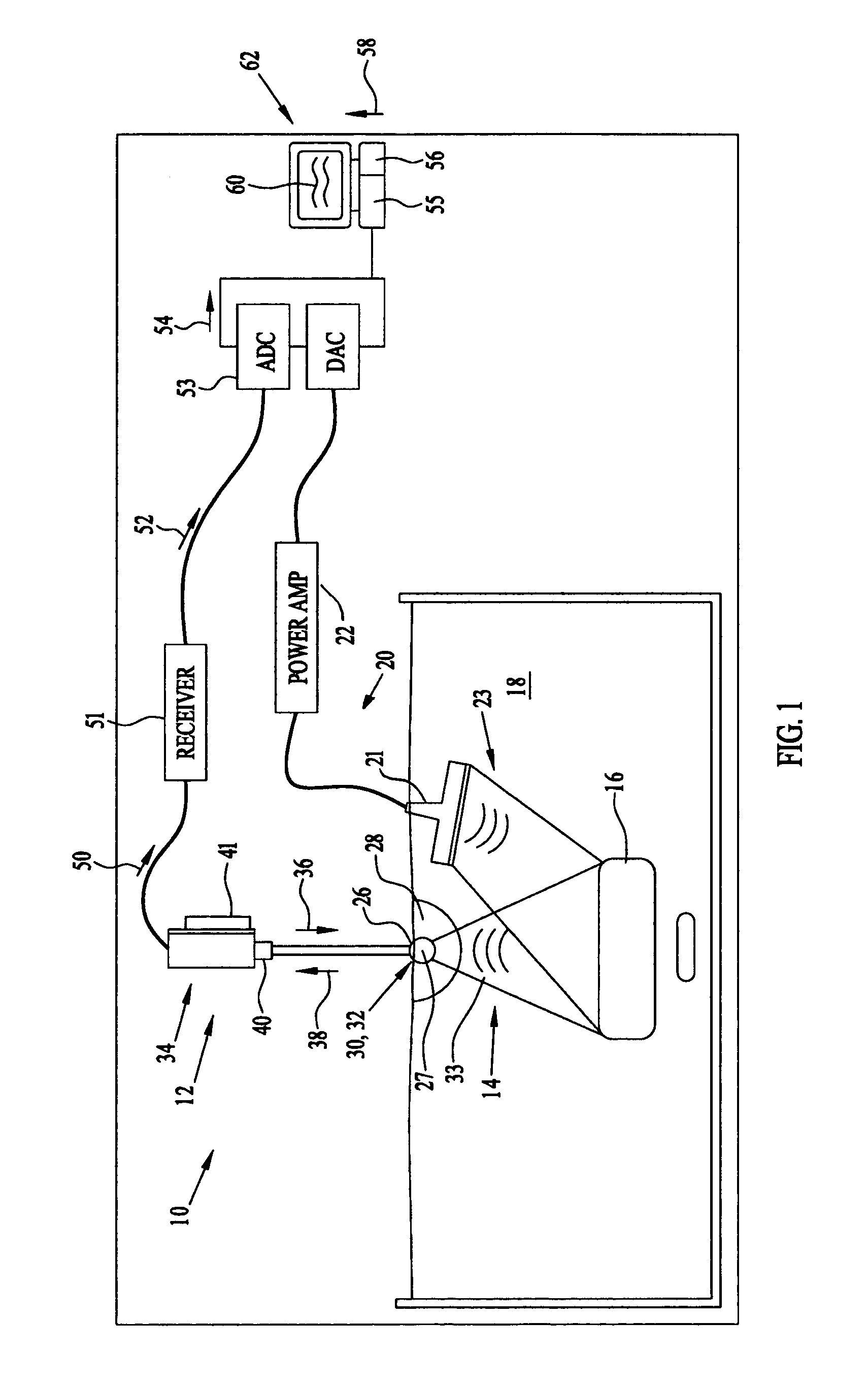

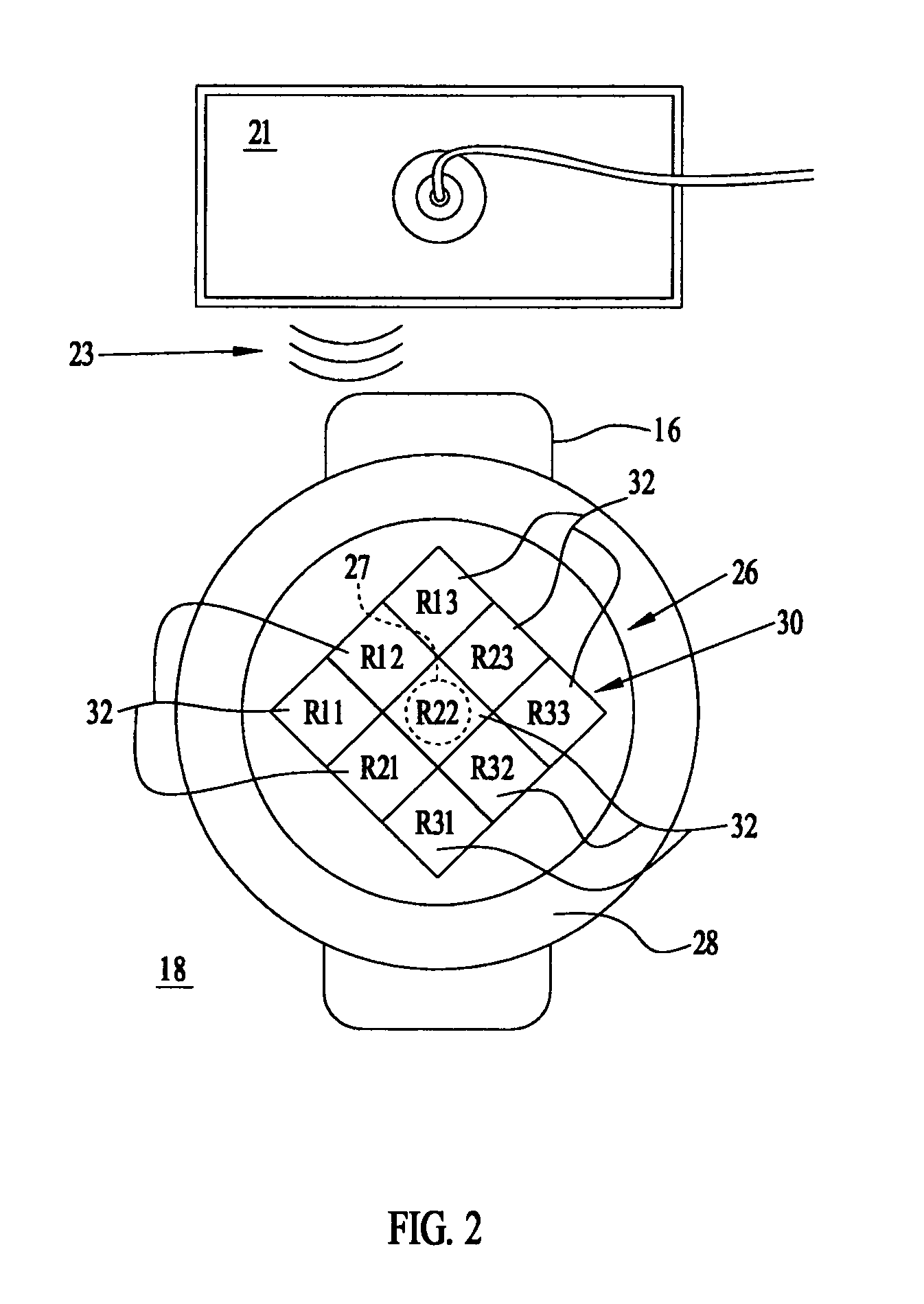

New devices and methods are provided for noninvasive and noncontact real-time measurements of tissue blood velocity. The invention uses a digital imaging device such as a detector array that allows independent intensity measurements at each pixel to capture images of laser speckle patterns on any surfaces, such as tissue surfaces. The laser speckle is generated by illuminating the surface of interest with an expanded beam from a laser source such as a laser diode or a HeNe laser as long as the detector can detect that particular laser radiation. Digitized speckle images are analyzed using new algorithms for tissue optics and blood optics employing multiple scattering analysis and laser Doppler velocimetry analysis. The resultant two-dimensional images can be displayed on a color monitor and superimposed on images of the tissues.

Owner:WINTEC LLC

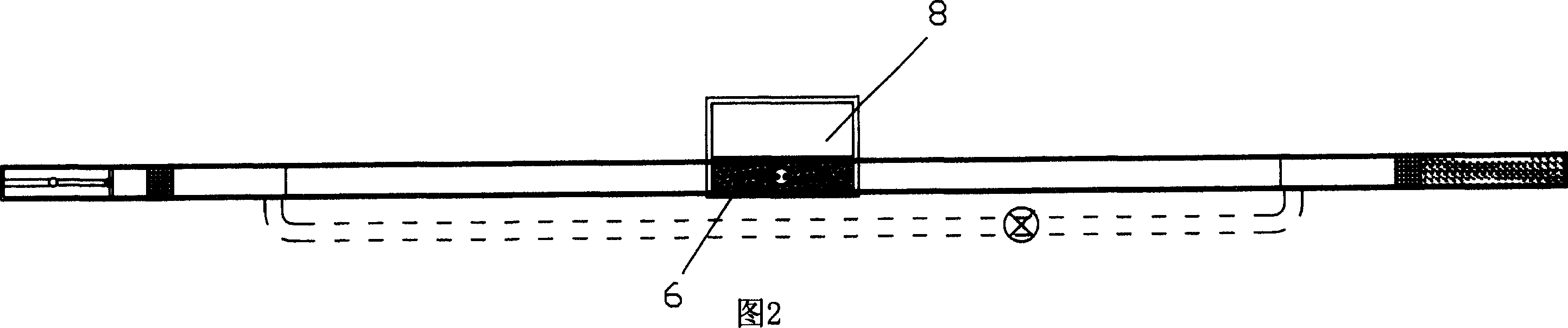

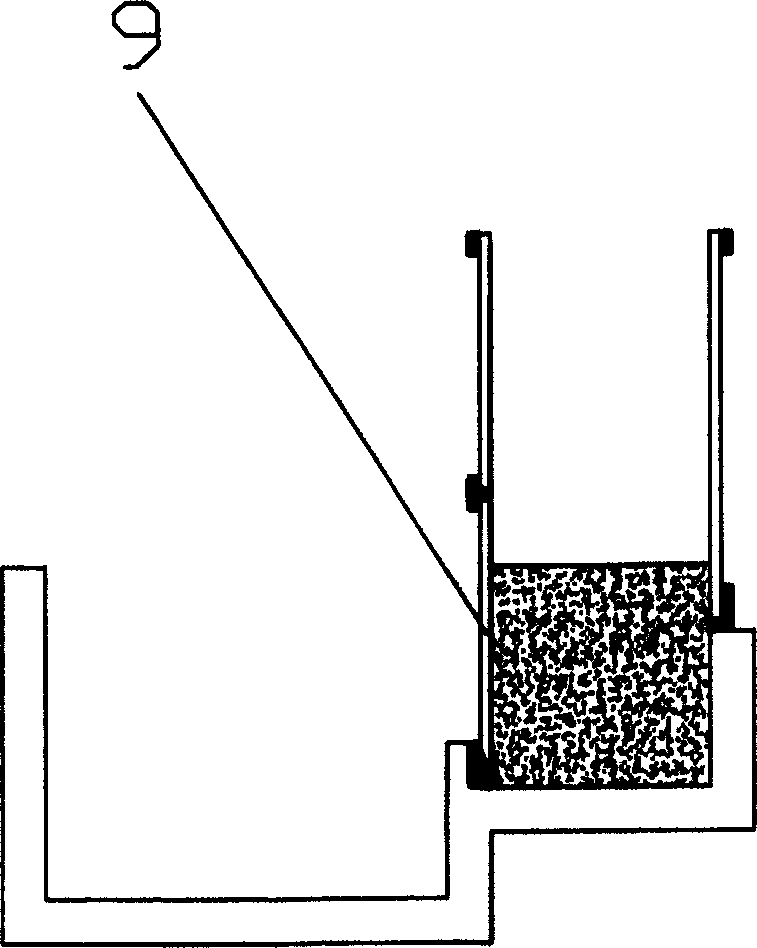

Wave flow-structural object-seabed power coupling experimental simulating method and appts. thereof

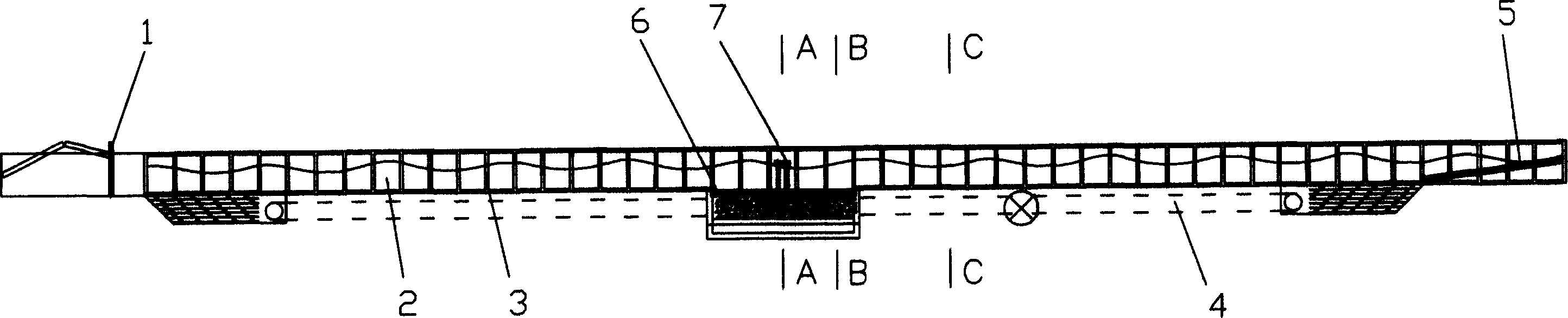

Simulated structure is sank to simulated seabed in simulated experimental flume, detecting is carried out for dynamic load borne by structure, dynamic response of key position and change of dynamic shift by using sensor. Height of wave, speed of flowfield around structure is detected through wave gage, velocimete for particle image and Doppler laser velocimeter. Dynamic response of soil mass is detected by using pore water pressure sensor and earth-pressure cell. Detected data are collected and processed synchronistically through multichannel data acquisition system in order to reproduce actual stress state of the structure. The invention also discloses simulated experimental flume, where there is simulated seabed soil mass filled.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

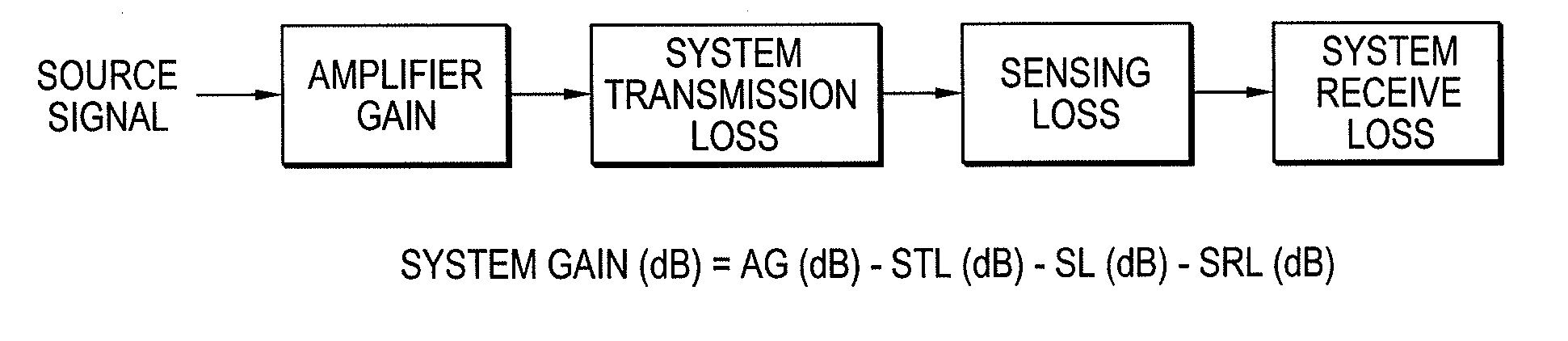

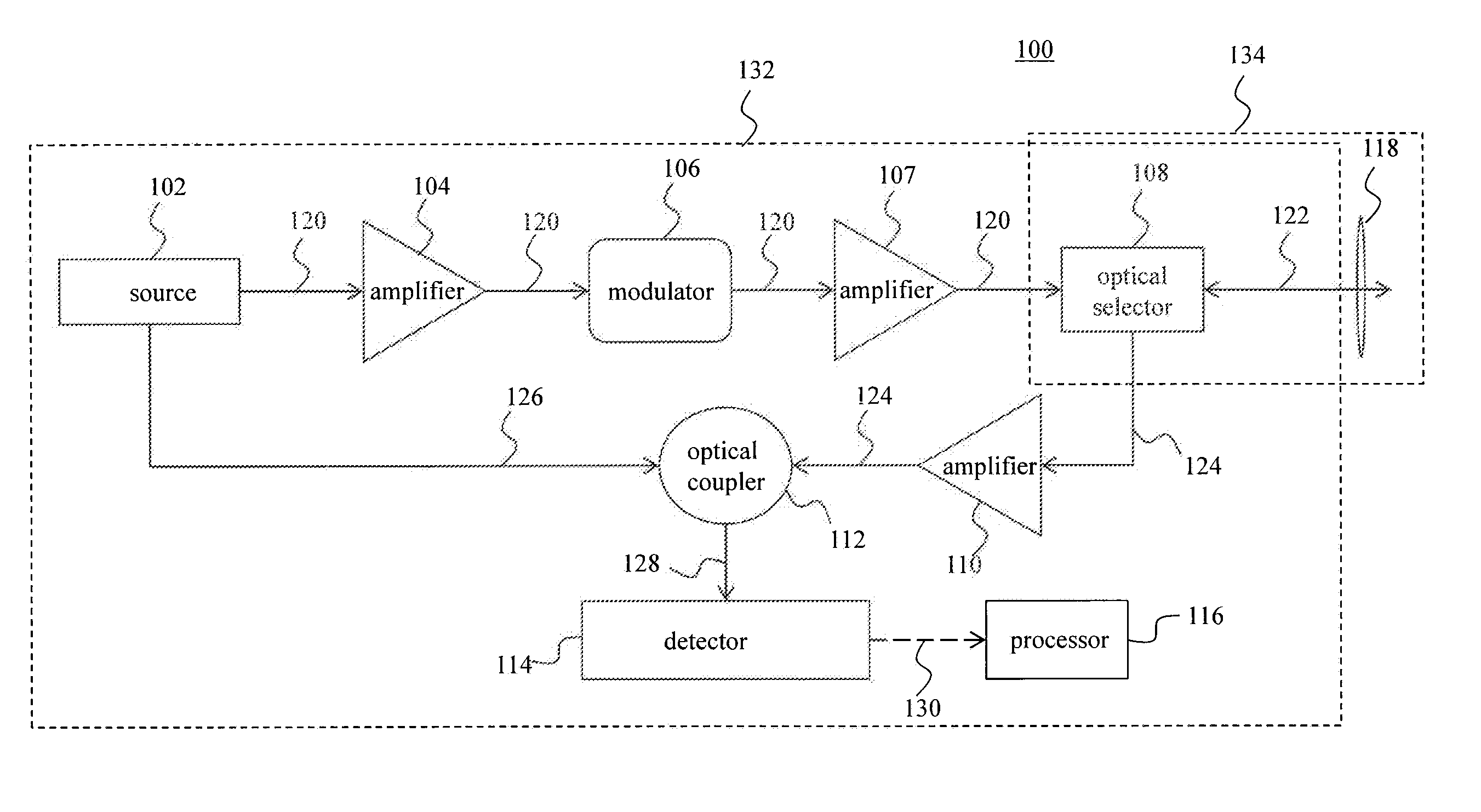

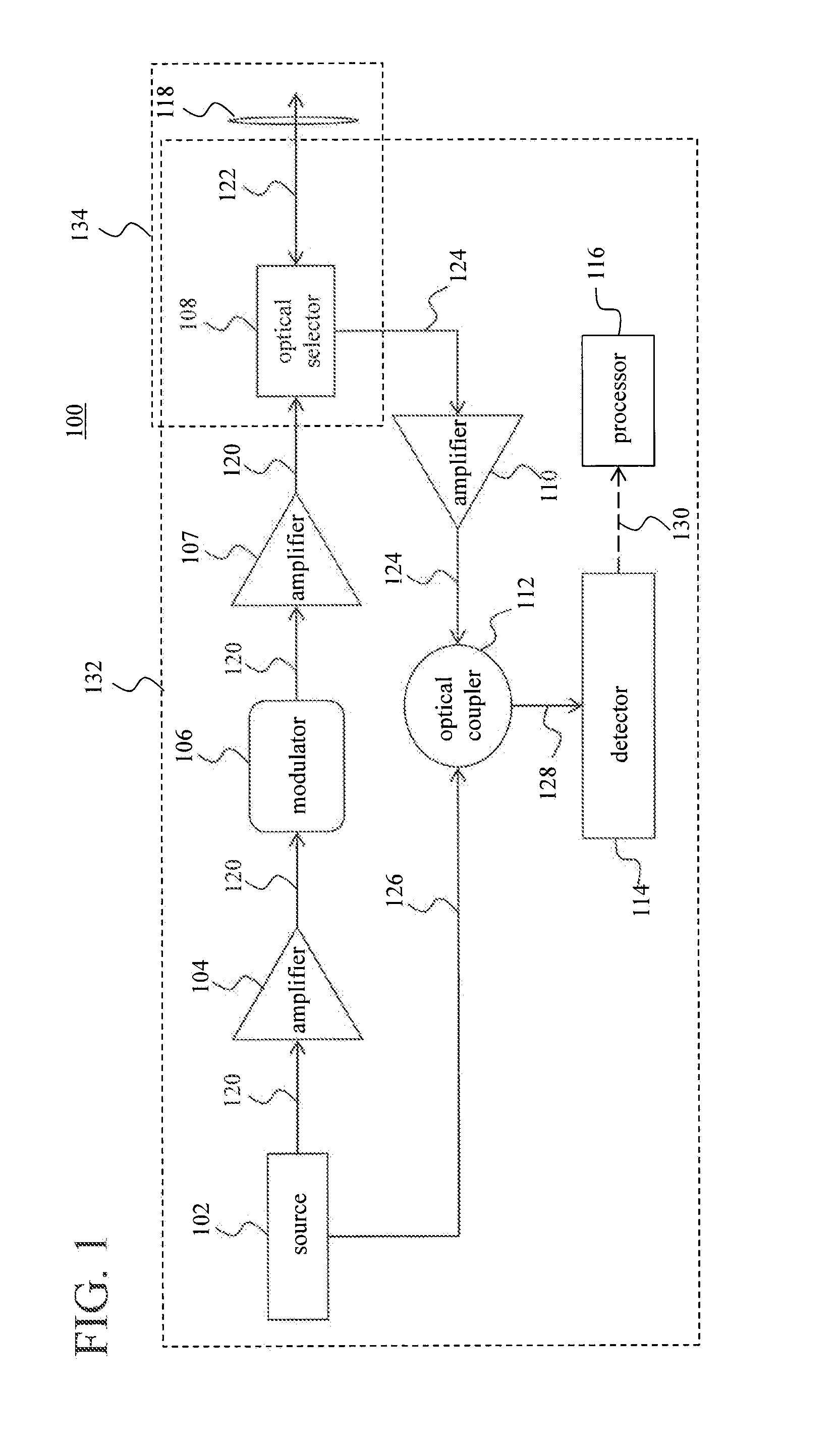

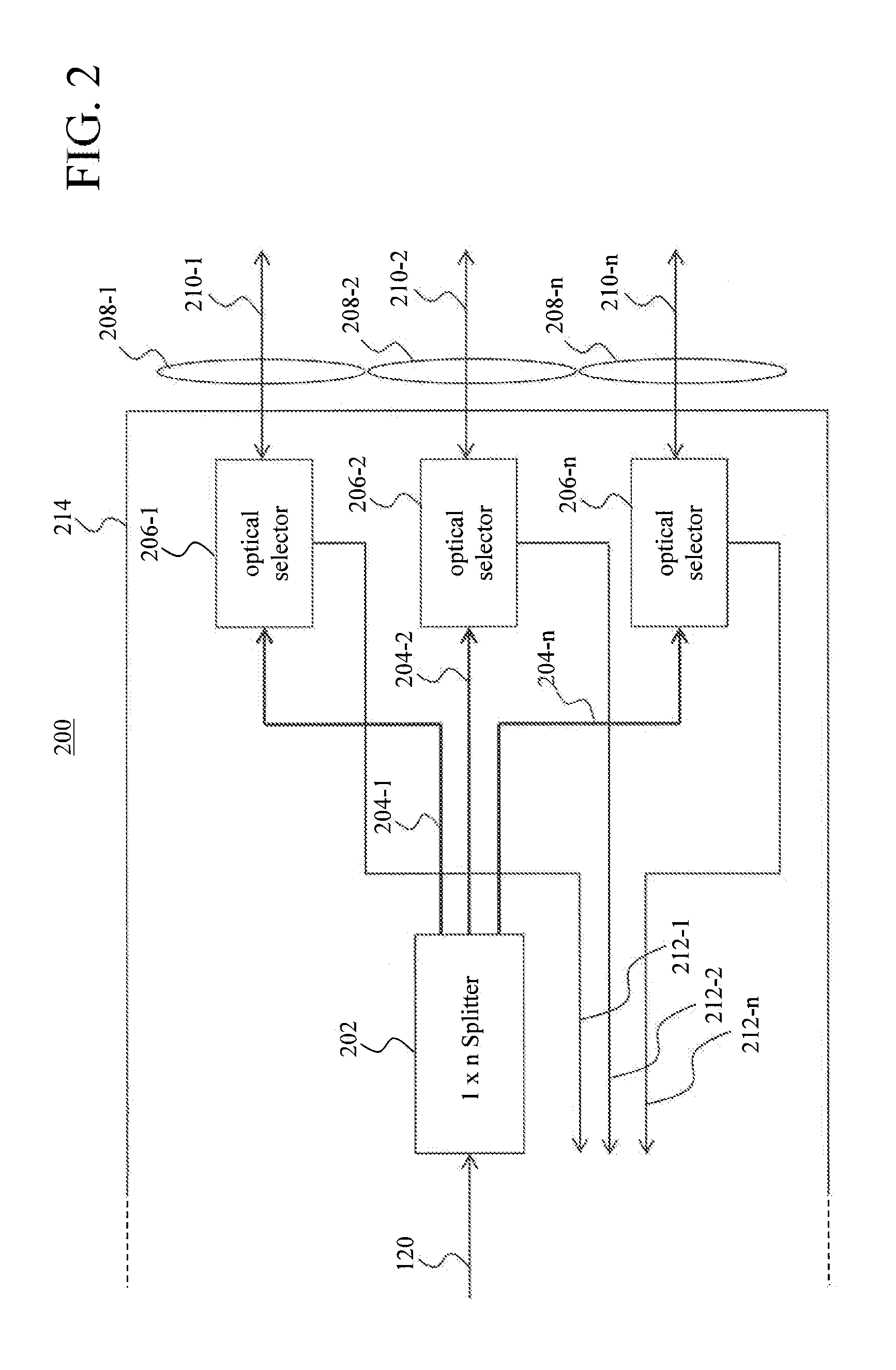

Amplified optical circuit

InactiveUS20150109605A1Certain costLower energy levelFibre transmissionActive medium shape and constructionMultiplexingAudio power amplifier

An optical circuit can include a bidirectional amplifier connected so as to amplify source light prior to emission through an output device such as a telescope as well as amplification of reflected light received by the telescope. Such an optical circuit can be used in laser doppler velocimeter applications as well as other applications. The optical circuit can also include passive splitters or active switches to provide for advantageous multiplexing.

Owner:SENSTHYS INC

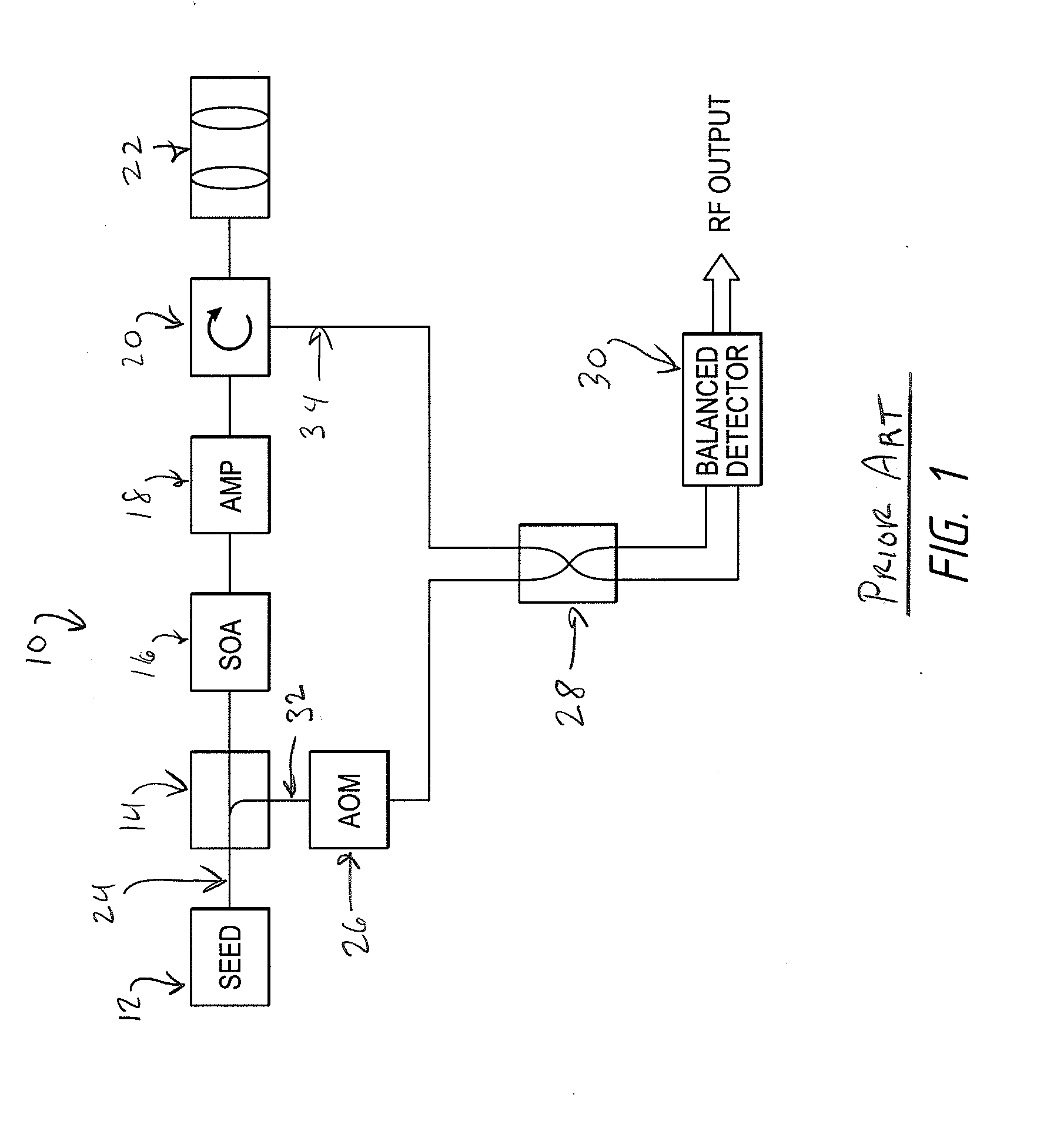

Laser Doppler Velocimeter Optical Electrical Integrated Circuits

InactiveUS20130083389A1Increase optical powerFibre transmissionActive medium shape and constructionTransceiverAudio power amplifier

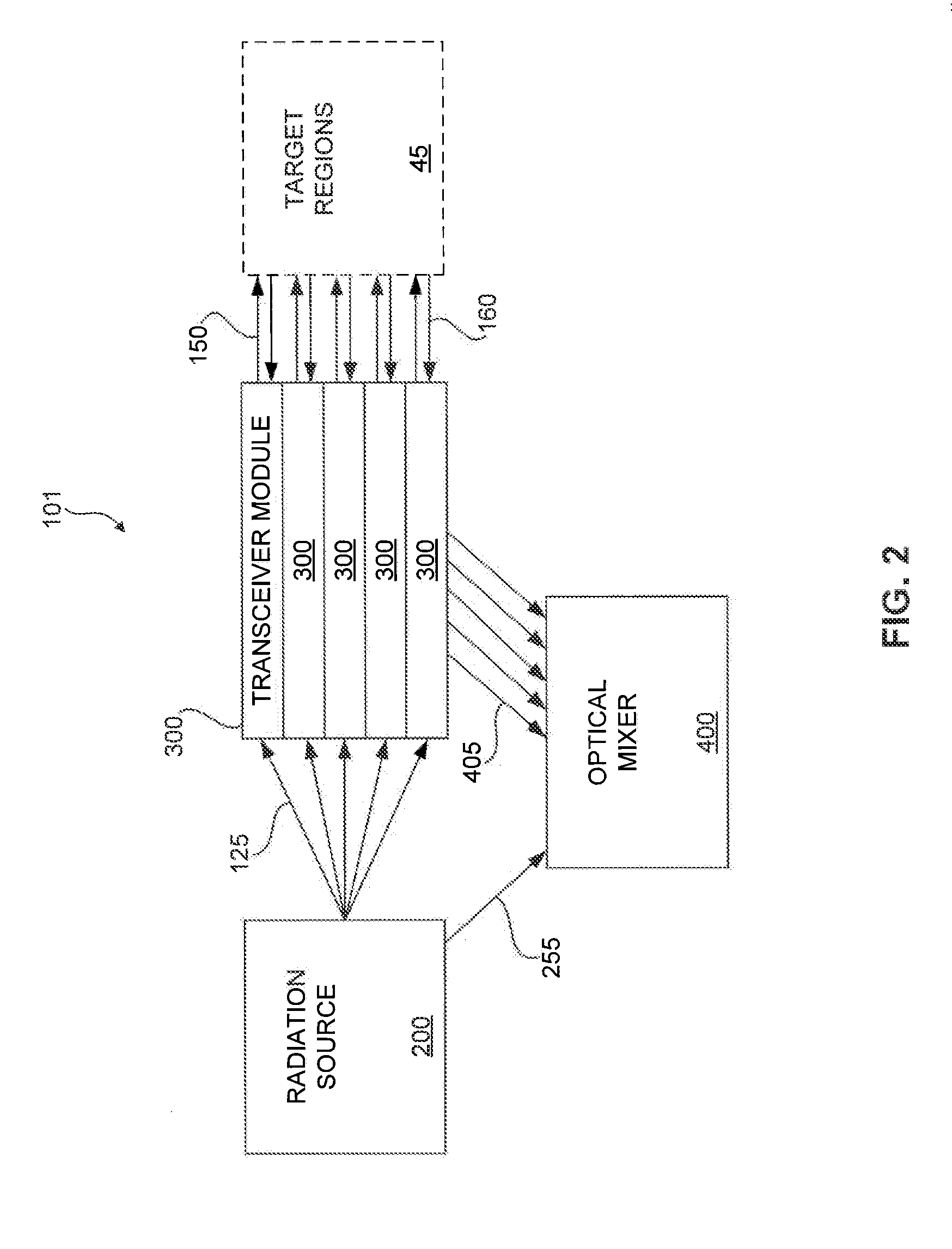

A photonic integrated circuit and related method are presented. A photonic integrated circuit comprises a source of radiation, one or more optical amplifiers, a transceiver, and optical waveguides. The optical waveguides couple light between the source of radiation, the one or more optical amplifiers, and the transceiver. The one or more optical amplifiers are configured to increase an optical power of the light up to at least 10 mW. The photonic integrated circuit may be used to perform laser Doppler velocimeter type measurements.

Owner:OPTICAL AIR DATA SYST

Laser Doppler Velocimeter With Intelligent Optical Device

InactiveUS20150185246A1Provide controlDevices using optical meansFluid speed measurementTransceiverLaser Doppler vibrometer

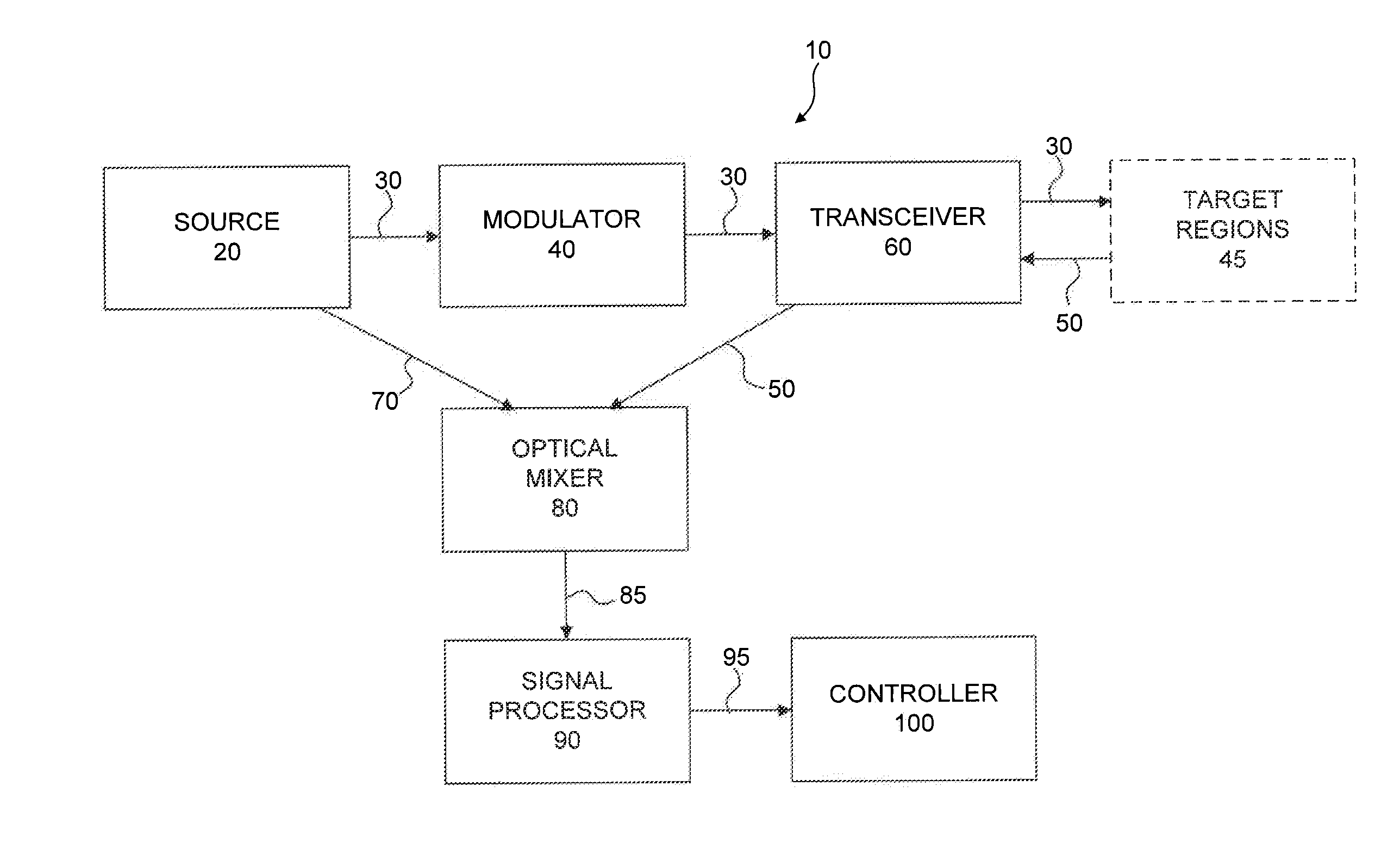

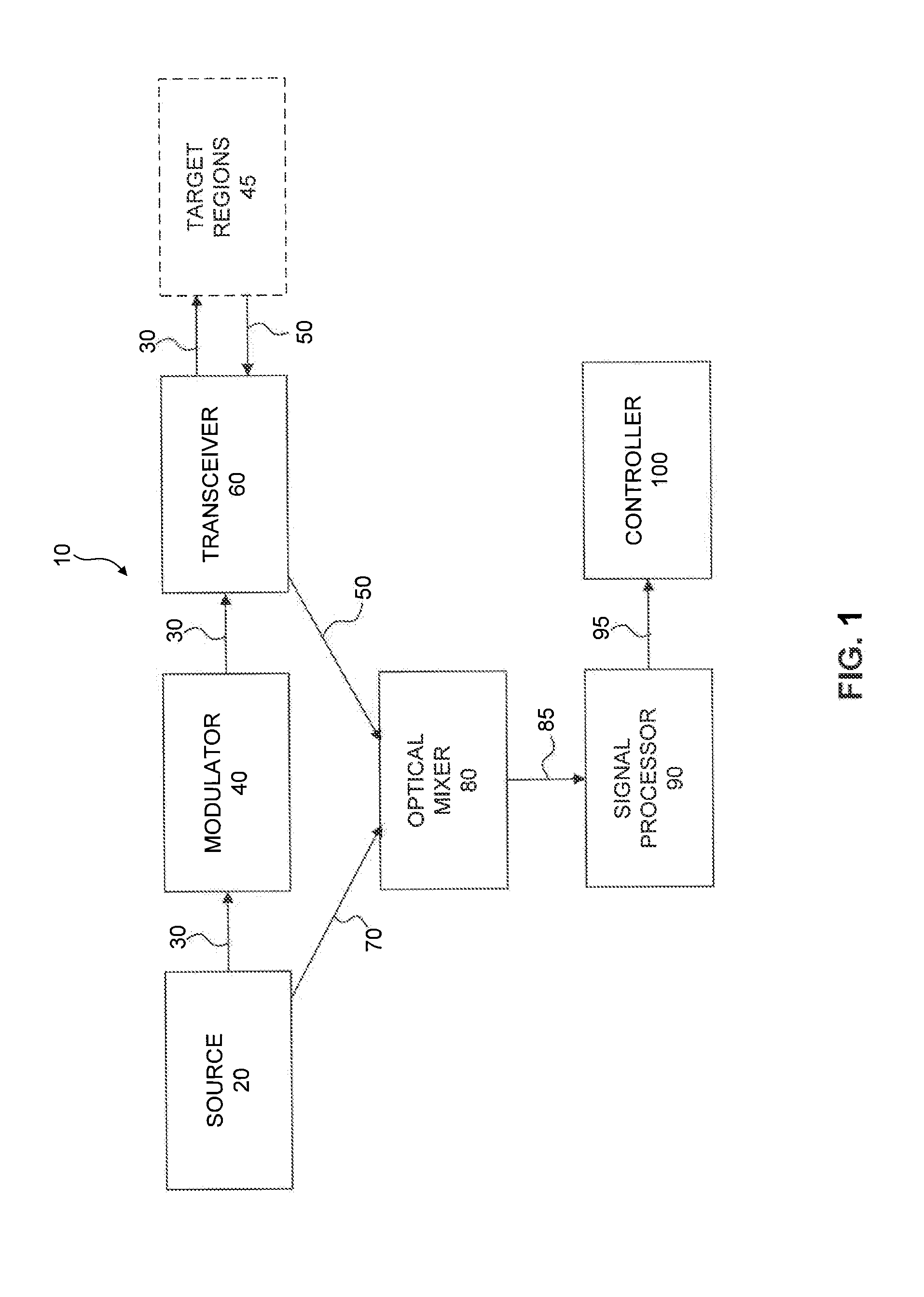

Systems and methods for laser based measurement of air parameters are disclosed. An example system includes a coherent source of radiation, a transceiver, an optical mixer, and an intelligent optical device. The coherent source produces a coherent radiation beam that is then transmitted to a target region by the transceiver. The transceiver is further configured to receive a scattered radiation signal from the target region. The optical mixer is configured to receive the scattered radiation signal from the transceiver, receive a reference radiation beam from the coherent source, and to determine a difference between the scattered radiation signal and the reference radiation beam. In certain embodiments, the intelligent optical device is configured to steer, modulate, or condition, at least one of the coherent radiation beam, the scattered radiation signal, and the reference radiation beam.

Owner:OPTICAL AIR DATA SYST

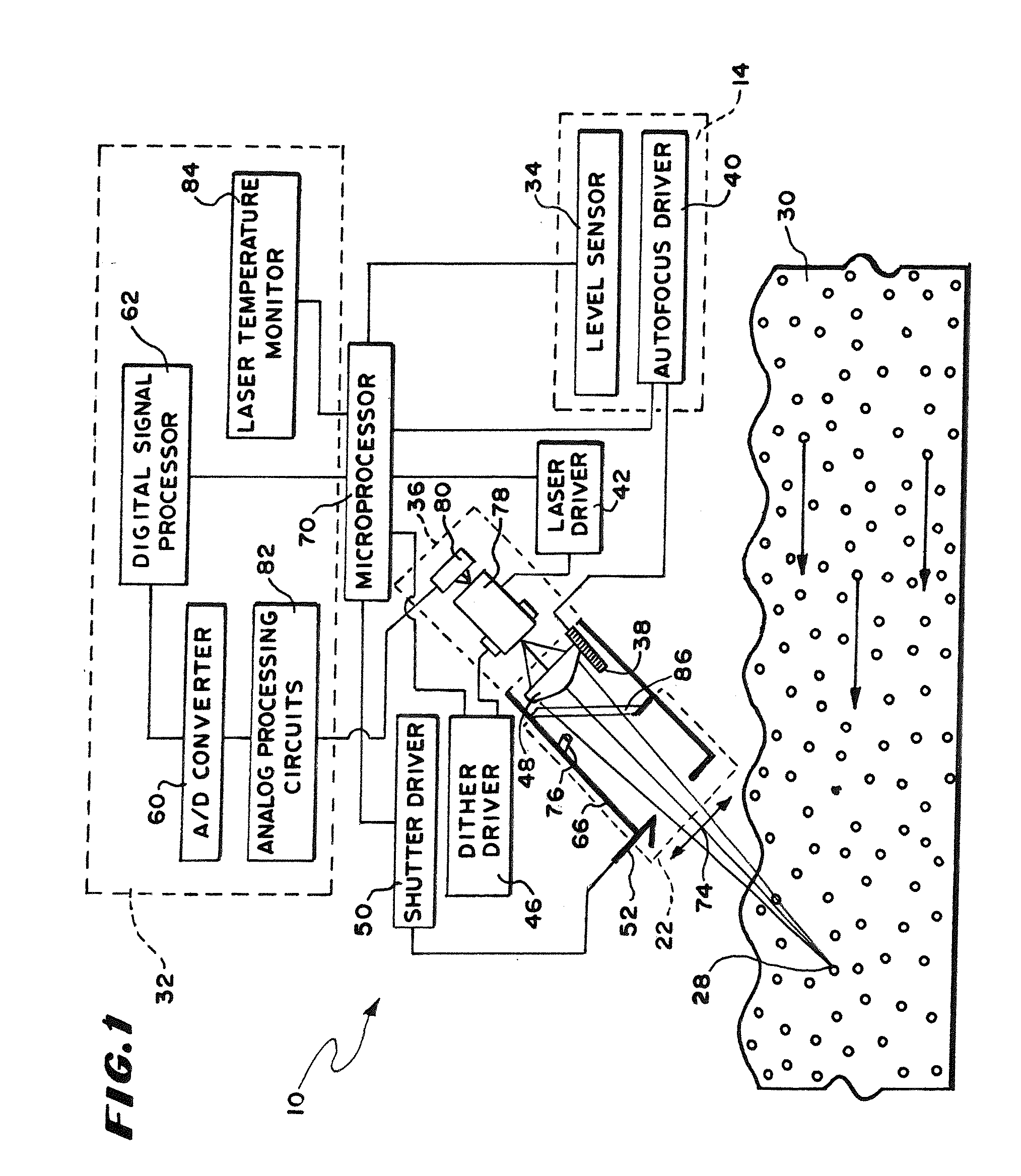

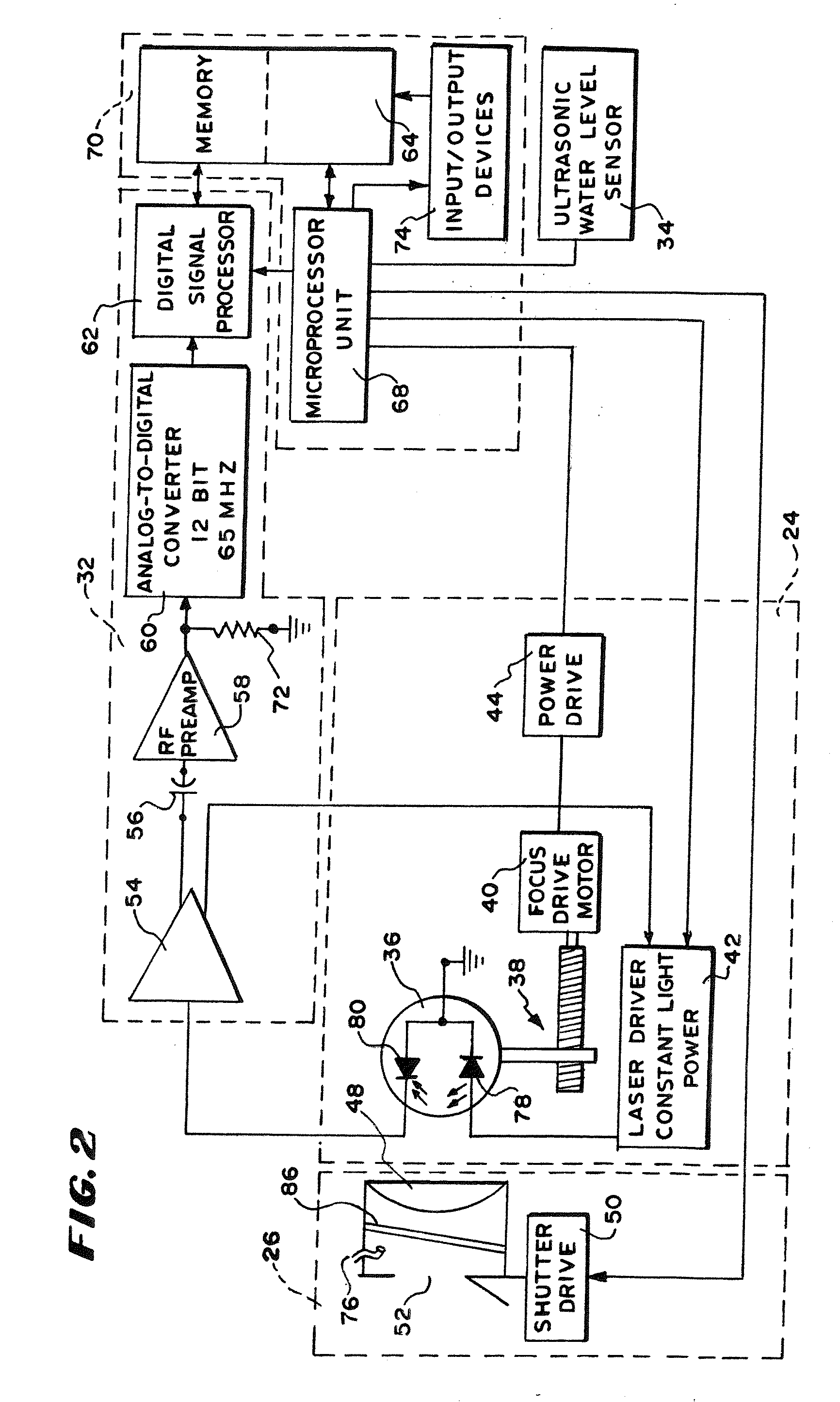

Velocity measuring system

ActiveUS20110285984A1High resolutionHigh precisionVolume/mass flow measurementFluid speed measurementData segmentSignal-to-quantization-noise ratio

A laser Doppler velocimeter uses self-mixing amplification of backreflections from scatterers below the surface of a flow.A time domain signal is divided into segments that are roughly equal to a transit time of particles through a focus of a laser beam. The segments are connected to a frequency domain through the use of an FFT algorithm to produce frequency domain data segments. Signal-to-noise ratio is enhanced through signal processing techniques using the segments to produce a final enhanced signal spectrum.

Owner:TELEDYNE

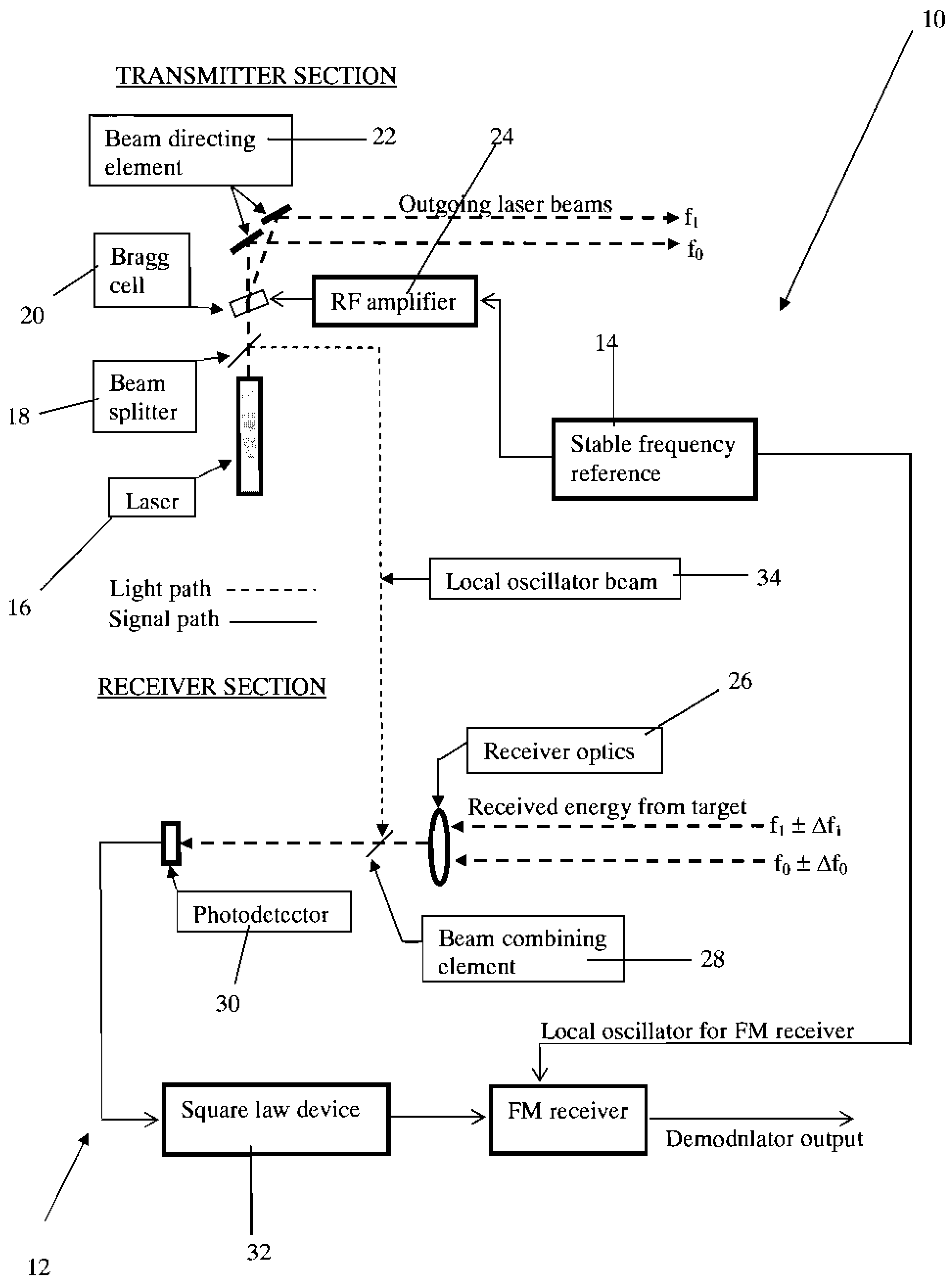

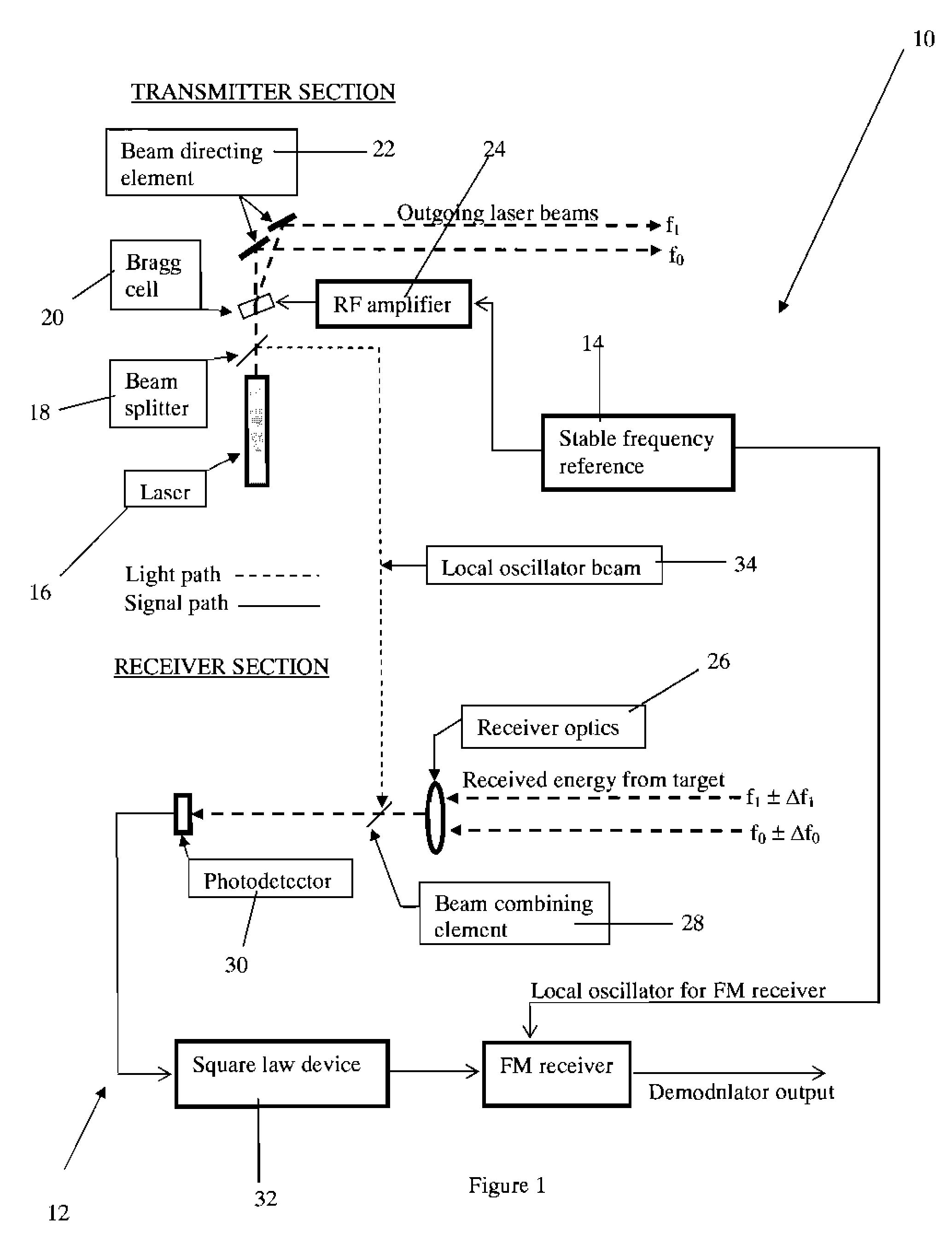

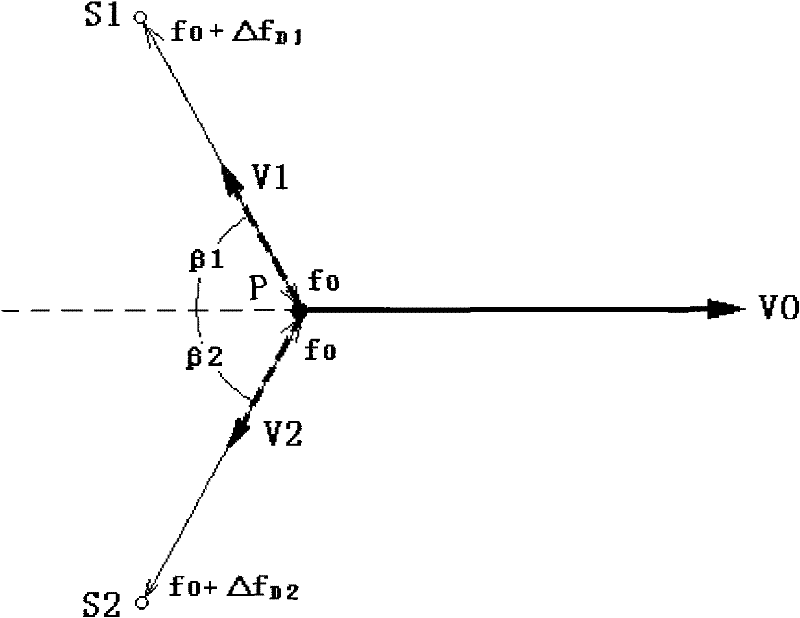

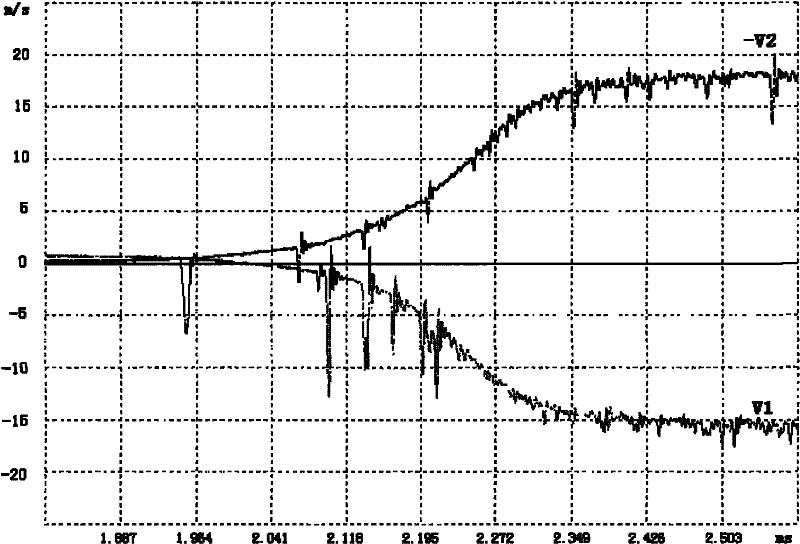

Fixed difference, dual beam laser Doppler velocimetry

A method and apparatus for laser Doppler velocity measurements with a fixed difference, dual beam receiver and using a non-laser, stable frequency reference.

Owner:KYRAZIS DEMOS T

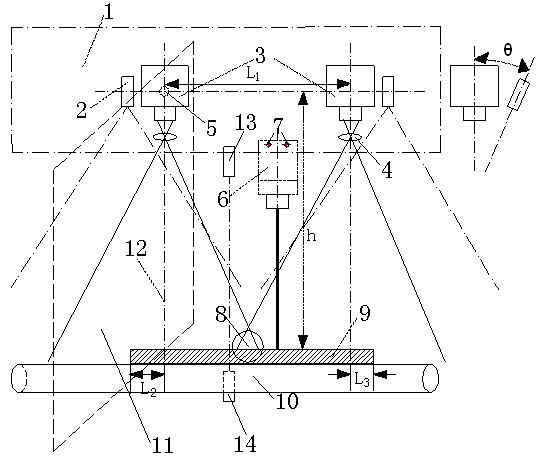

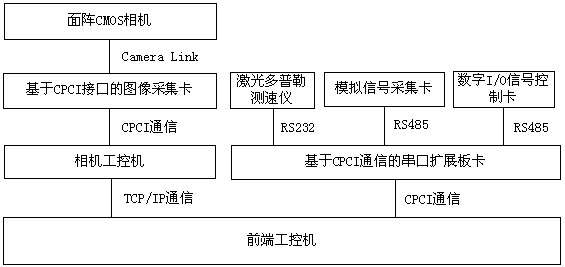

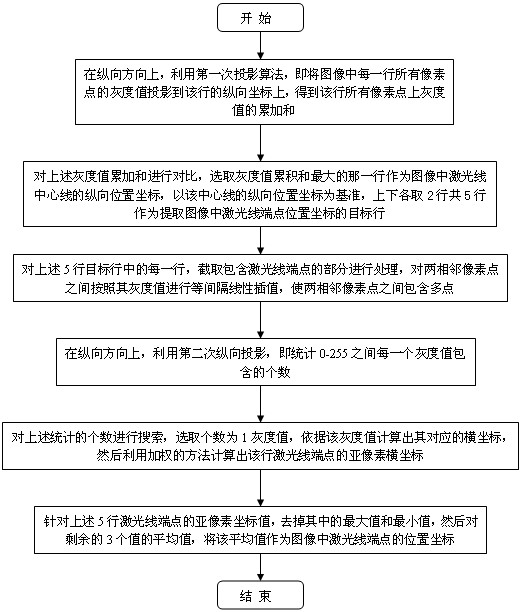

Secondary-projection-algorithm-based on-line non-contact contour detection system and method of intermediate-thick plate

The invention discloses a secondary-projection-algorithm-based on-line non-contact contour detection system and method of an intermediate-thick plate. In the system, an area array CMOS (Complementary Metal-Oxide-Semiconductor) camera is used for acquiring an image of linear laser entering a band steel surface of the intermediate-thick plate; the shot image is processed by utilizing the secondary projection algorithm to precisely extract the longitudinal position coordinate of a laser line and the end point position coordinate of the laser line from the image; height information of the surface of the intermediate-thick plate can be calculated through the longitudinal position coordinate of the laser line; the space position coordinate of the edge of a band steel to be detected can be determined according to the height information of the surface of the intermediate-thick plate and the end point position coordinate of the laser line by virtue of vision calibration of the camera; a contour curve of the band steel of the intermediate-thick plate can be obtained after the speed data of the band steel, which is measured by a laser Doppler velocimetry, is processed by a computer. Through adoption of the system and method disclosed by the invention, on-line non-contact type high-speed detection of the contours of two sides of the band steel of the intermediate-thick plate is realized and on-line non-contact type high-speed detection of the contours of the head and the tail of the band steel of the intermediate-thick plate is realized.

Owner:浙江浙大网新环境工程有限公司

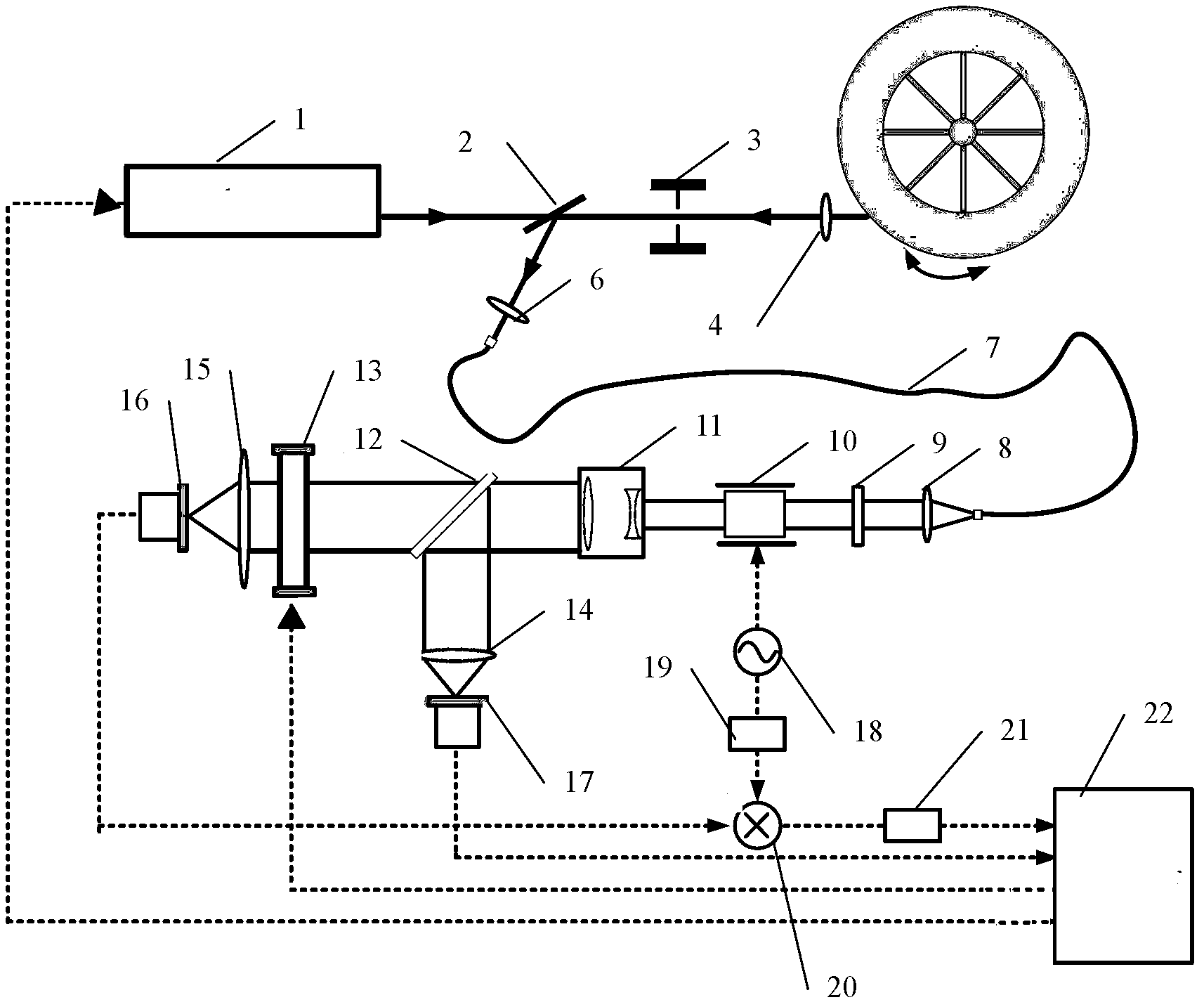

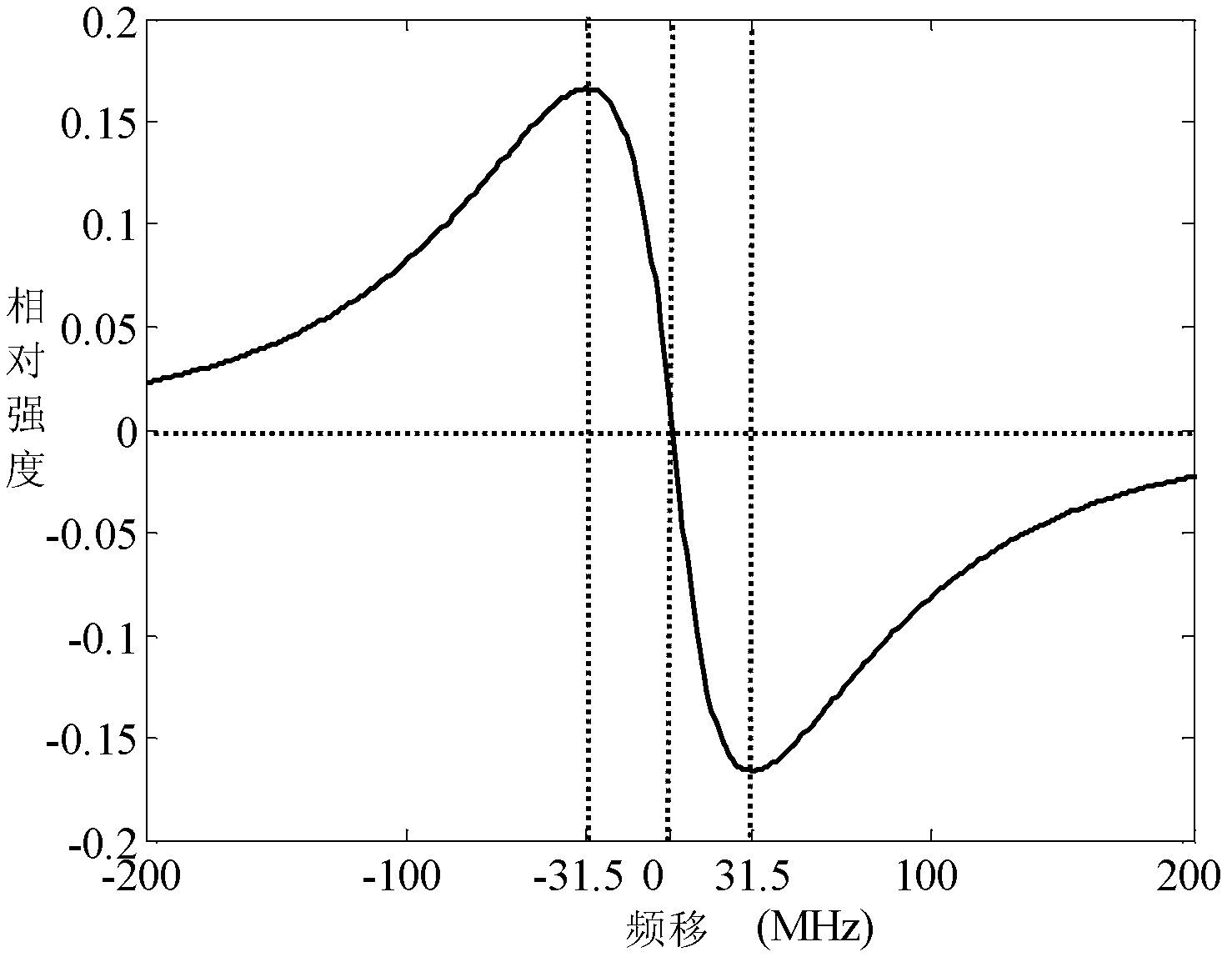

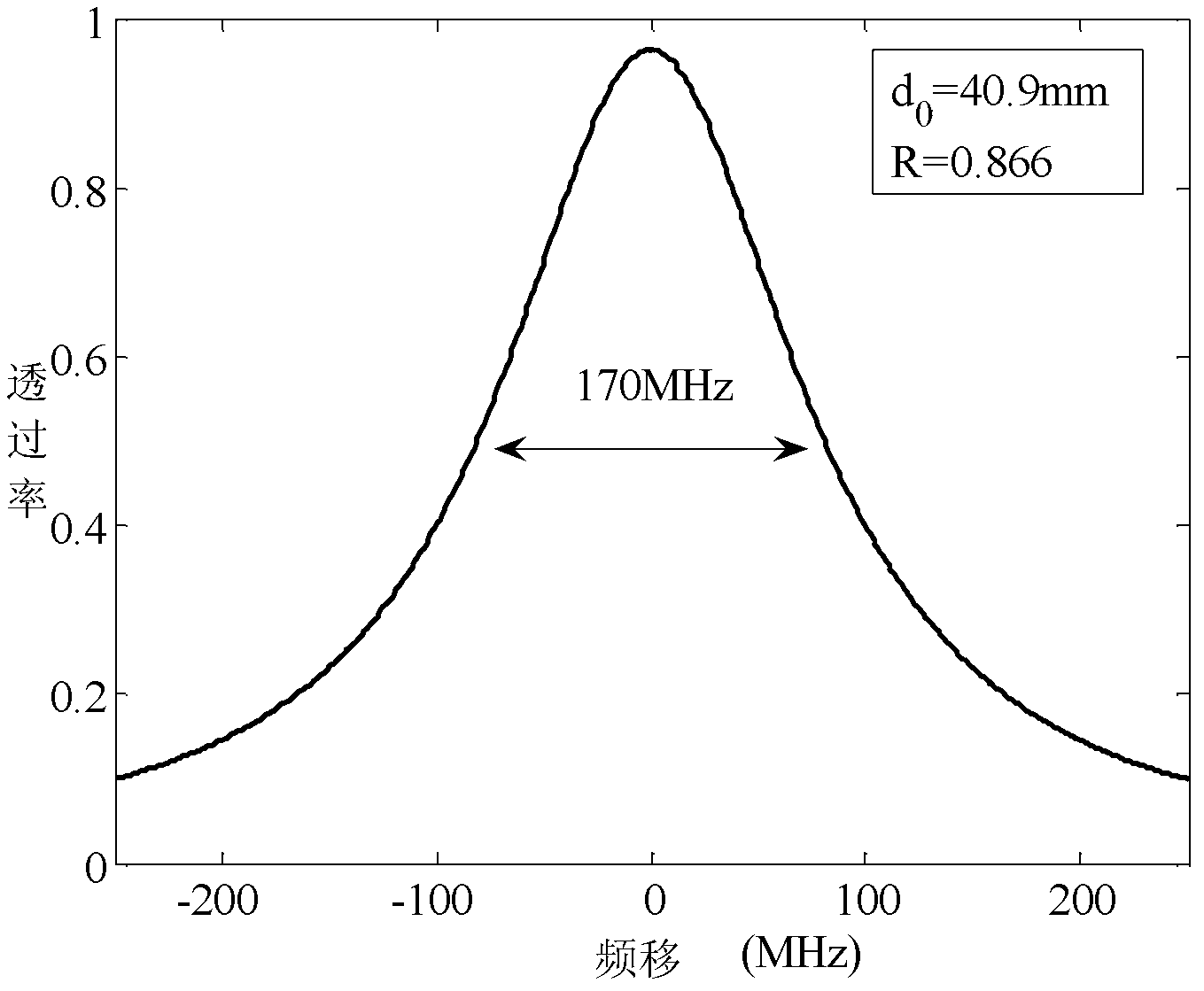

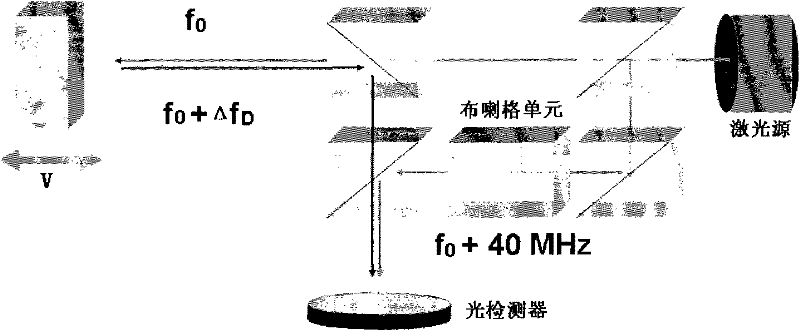

Phase modulation direct detection laser Doppler velometer and velocity measuring method thereof

InactiveCN103163530AAvoid noiseImprove signal-to-noise ratioElectromagnetic wave reradiationVibration amplitudeLow-pass filter

The invention discloses a phase modulation direct detection laser Doppler velometer and a velocity measuring method thereof, and relates to a direct detection laser Doppler velometer. In order to solve the problem that a method of converting frequency change of back scattering light into the change of transmittance by utilizing edge filters of a Fabry-Perot (F-P) interferometer in the current direct detection mode to obtain Doppler frequency shift is low in measuring accuracy relative to a coherent detection mode, the invention provides the phase modulation direct detection laser Doppler velometer and the velocity measuring method thereof. According to the method, a beat frequency signal of which the vibration amplitude is changed with the Doppler frequency shift of a moving target is generated by an electric-optical phase modulator and the FP interferometer; a vibration amplitude item is extracted by a phase shifter, a multiplying unit and a low-pass filter, and optical wave frequency information is identified by utilizing the vibration amplitude item; and the frequency of emitted laser and target back scattering light is measured by utilizing the turning-on state and turning-off state of a mechanical switch, and difference of two-time frequency measuring values is used as a measuring value of the Doppler frequency shift. According to the phase modulation direct detection laser Doppler velometer, the influence of the change of light intensity on a measuring result is removed by the energy detection of backward waves, so that the phase modulation direct detection laser Doppler velometer is used for measuring the movement velocity of targets in the field of optics.

Owner:HARBIN INST OF TECH

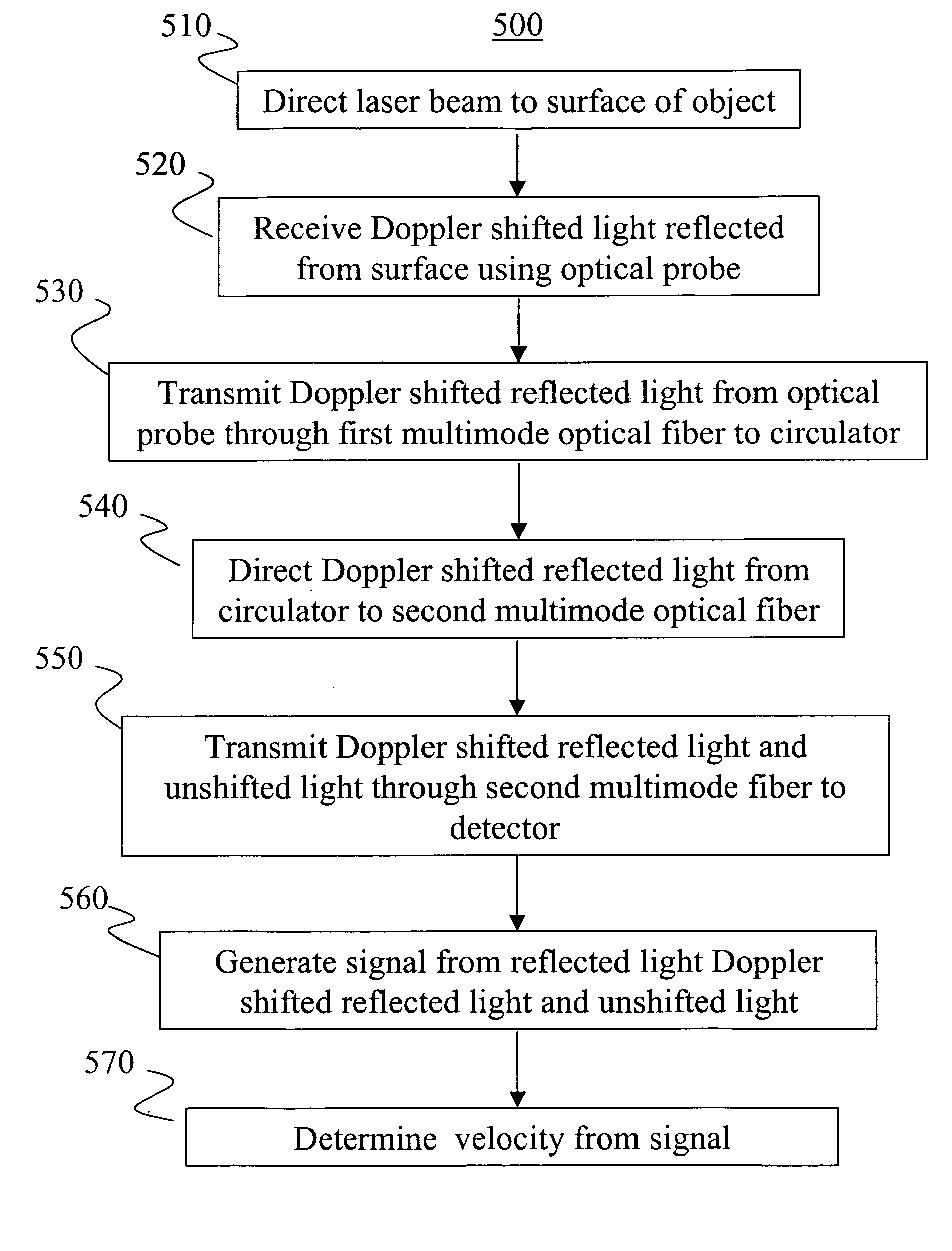

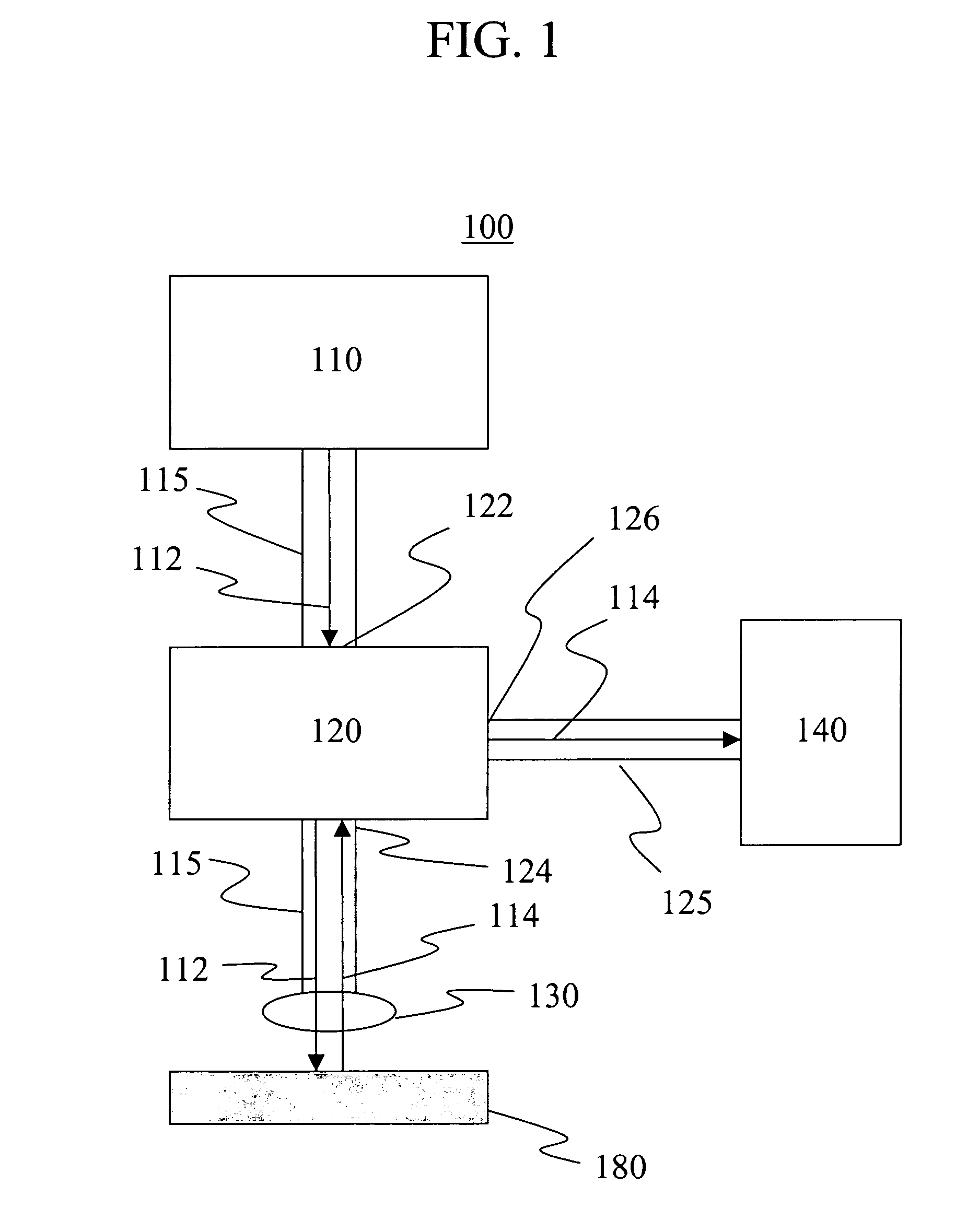

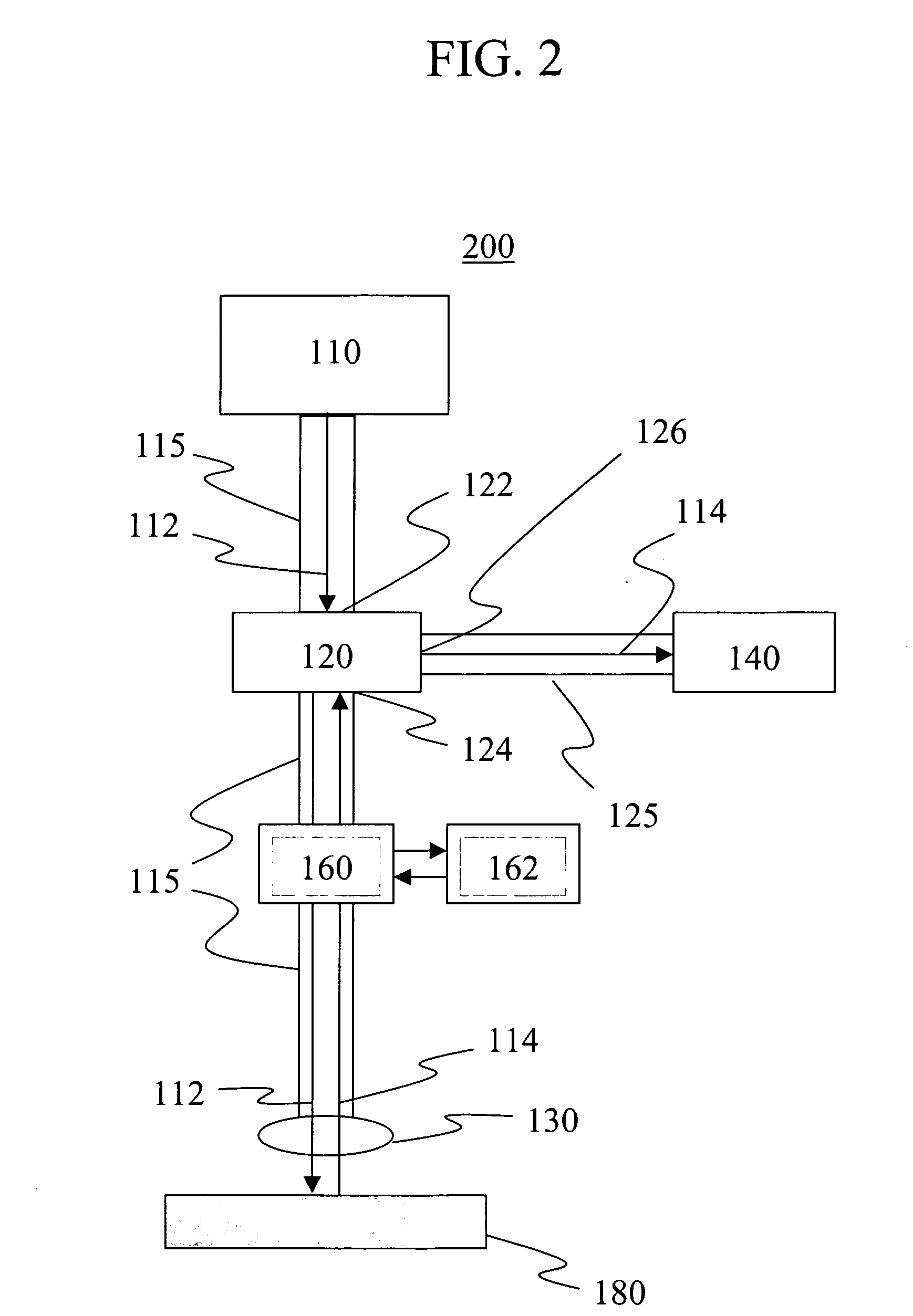

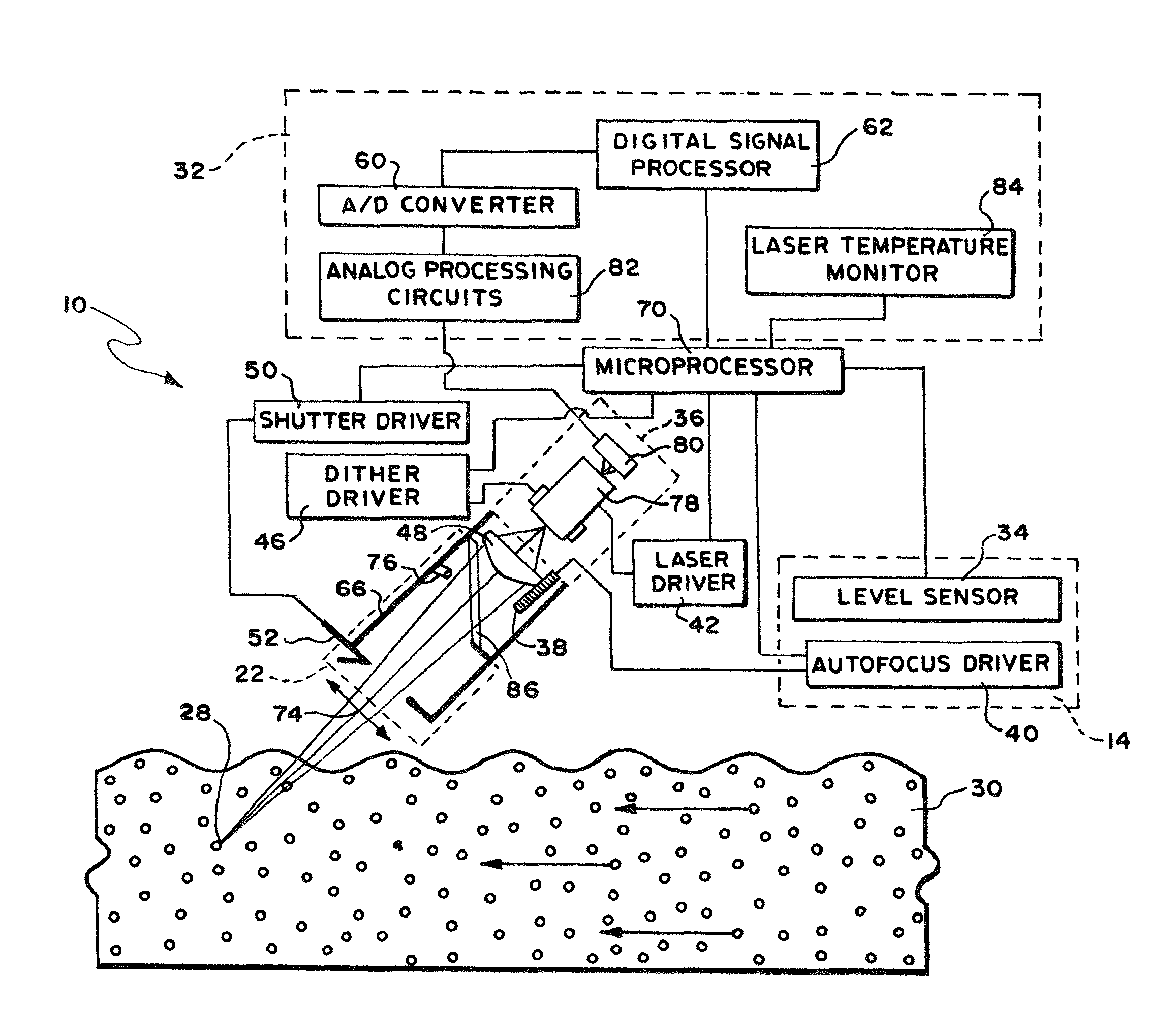

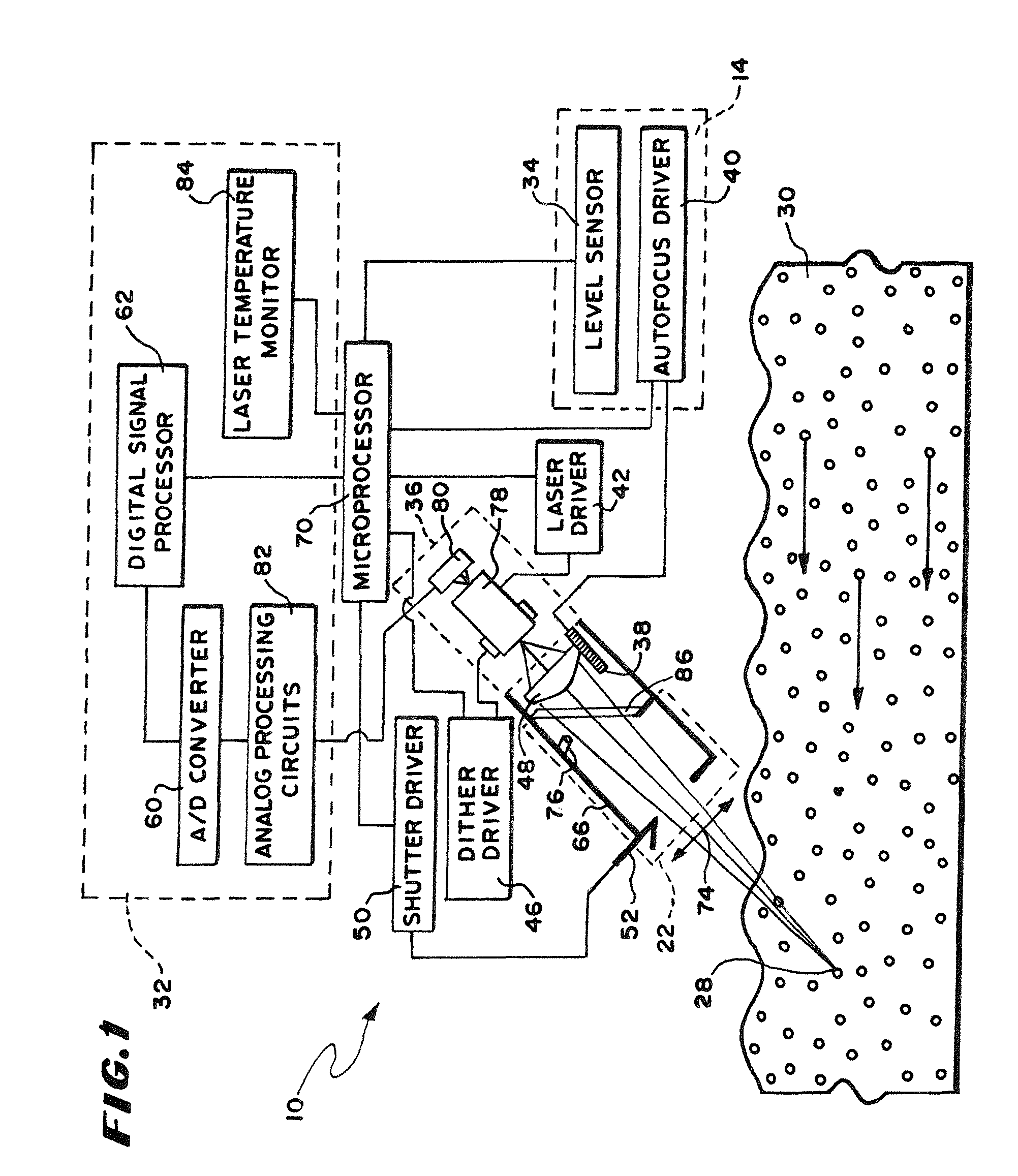

Laser velocimetry system

InactiveUS20080094608A1Low powerDevices using optical meansElectromagnetic wave reradiationElectronLaser velocimetry

A laser velocimetry system that employs a low power laser. The laser has a power of up to about 100 mW. Light from the laser, in one embodiment, is directed through a multimode optical fiber and an optical probe to a surface of a moving sample. Doppler-shifted light from the surface is reflected back through the optical probe and multimode optical fiber to a circulator, which directs the light reflected from the surface to a second multimode optical fiber. Unshifted (i.e., non-Doppler shifted) light is also introduced into the optical signal path. The Doppler shifted reflected light and the unshifted light are then transmitted through the second multimode optical fiber to a detector, which converts the reflected light into an electronic signal. The electronic signal of the “beat” between the Doppler shifted light and unshifted light may then be digitized by an analyzer and used to determine the velocity of the moving surface. A method of determining the velocity of a moving object is also described.

Owner:RGT UNIV OF CALIFORNIA

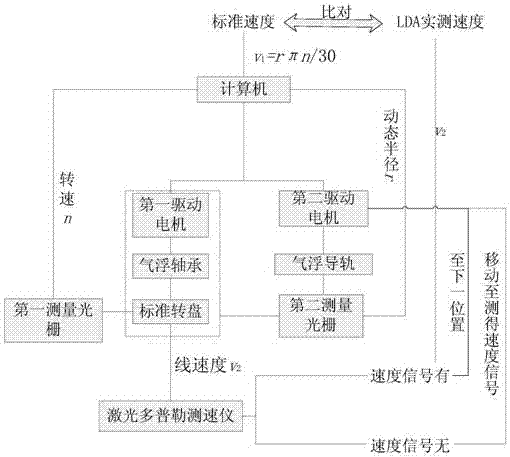

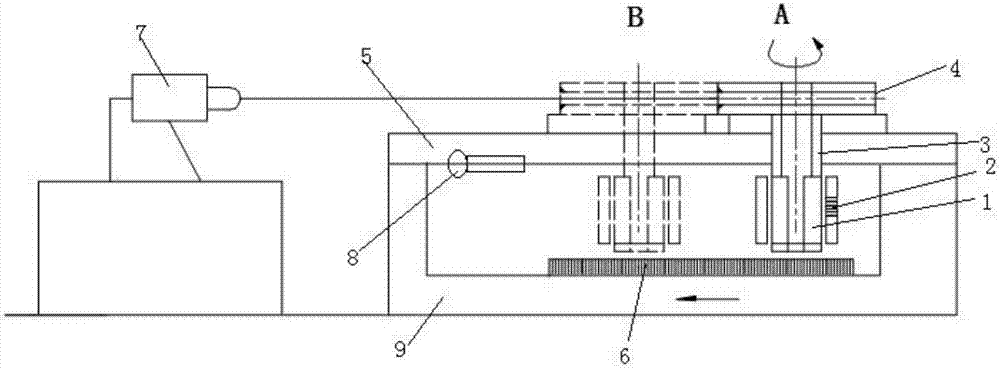

Laser Doppler speed measurement and calibration device based on dynamic radius measurement

InactiveCN107085126ARealize traceabilityRaise the level of uncertaintyTesting/calibration of speed/acceleration/shock measurement devicesGratingDrive motor

The invention particularly relates to a laser Doppler speed measurement and calibration device based on dynamic radius measurement, and belongs to the field of wind speed measurement and calibration. The device comprises a driving motor, an air floating shaft system, an air floating guide rail, a laser Doppler speed measurement device, a standard rotary disc, a measurement optical grating, a substrate and a computer. According to the invention, by taking the dynamic radius measurement of a standard rotary disc under different rotation speeds as the core technology, the dynamic radius of the standard rotary disc is obtained by use of a laser Doppler speed measurement mode; standard linear speed generated by the standard rotary disc is acquired and compared with the speed measured by the laser Doppler speed measurement device, so calibration of the laser Doppler speed measurement device is finished; traceability of flow speed parameters can be achieved; the device is superior to a traditional speed measurement and calibration method; and meanwhile, by use of the high precision driving motor, and using the grinding technology to manufacture the precise air floating shaft system and the air floating guide rail, the uncertainty level of the calibration device is increased.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

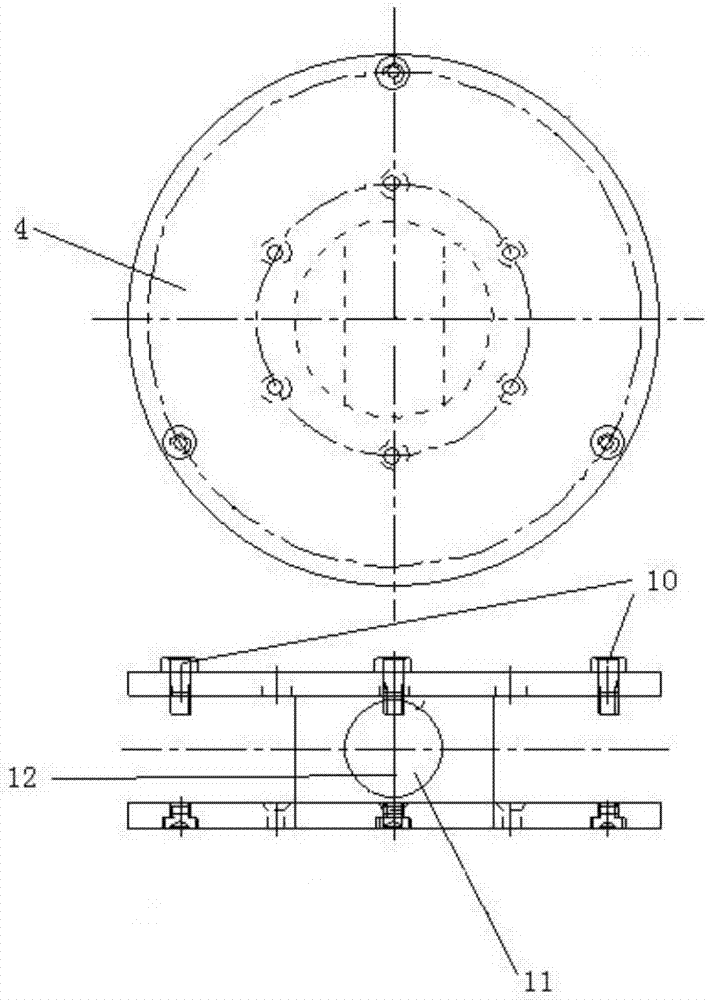

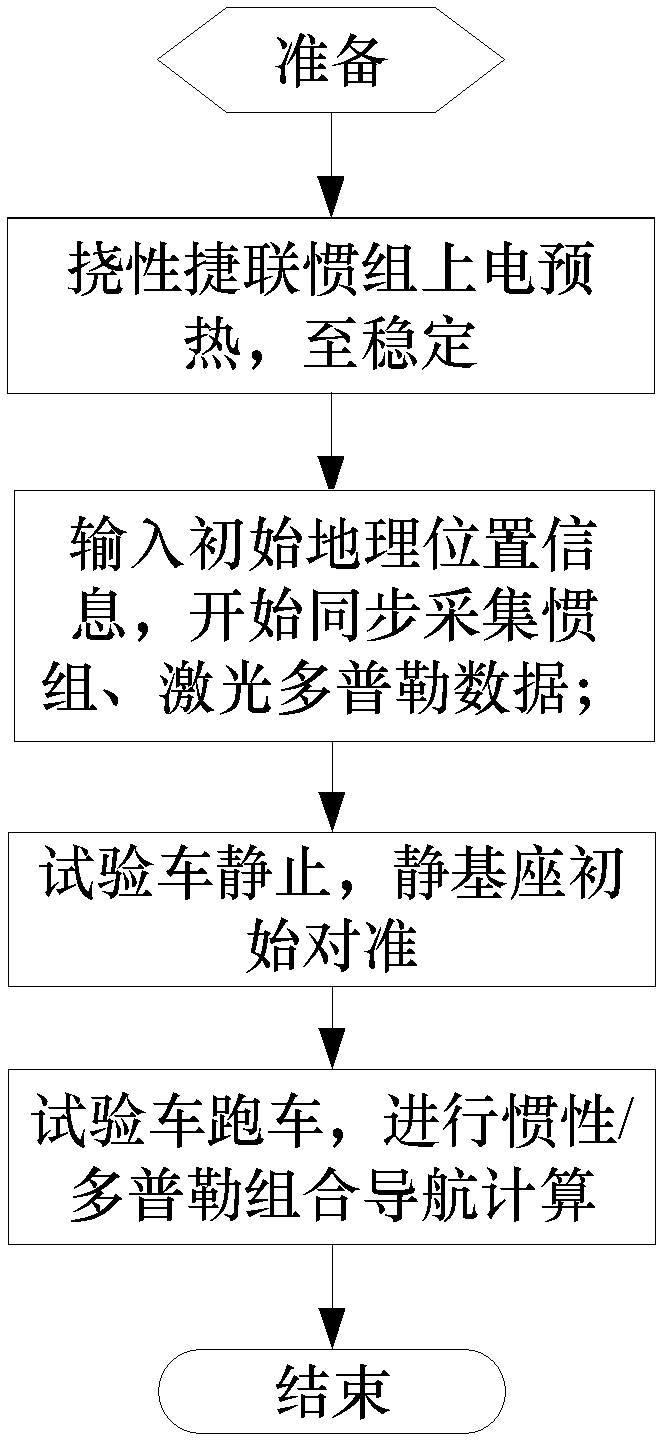

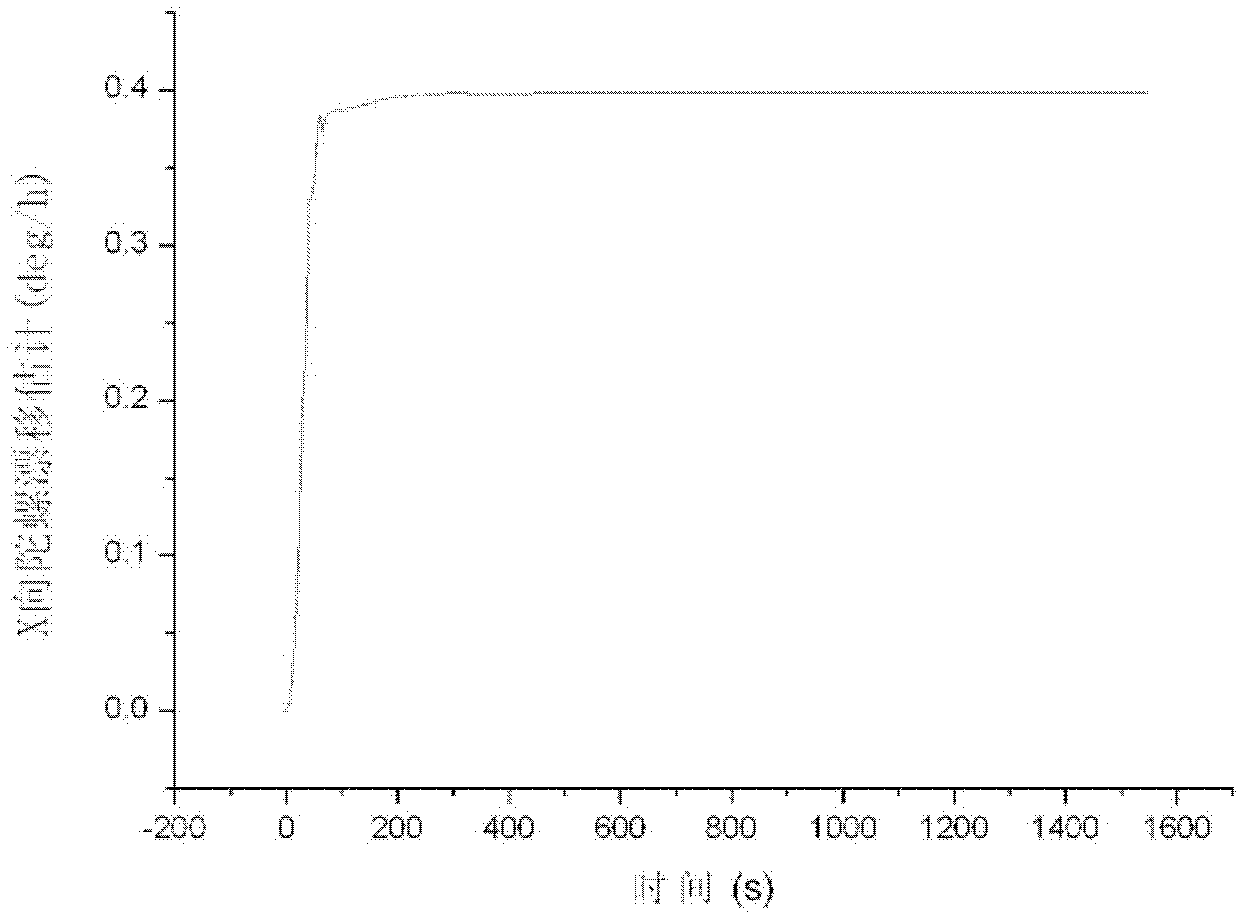

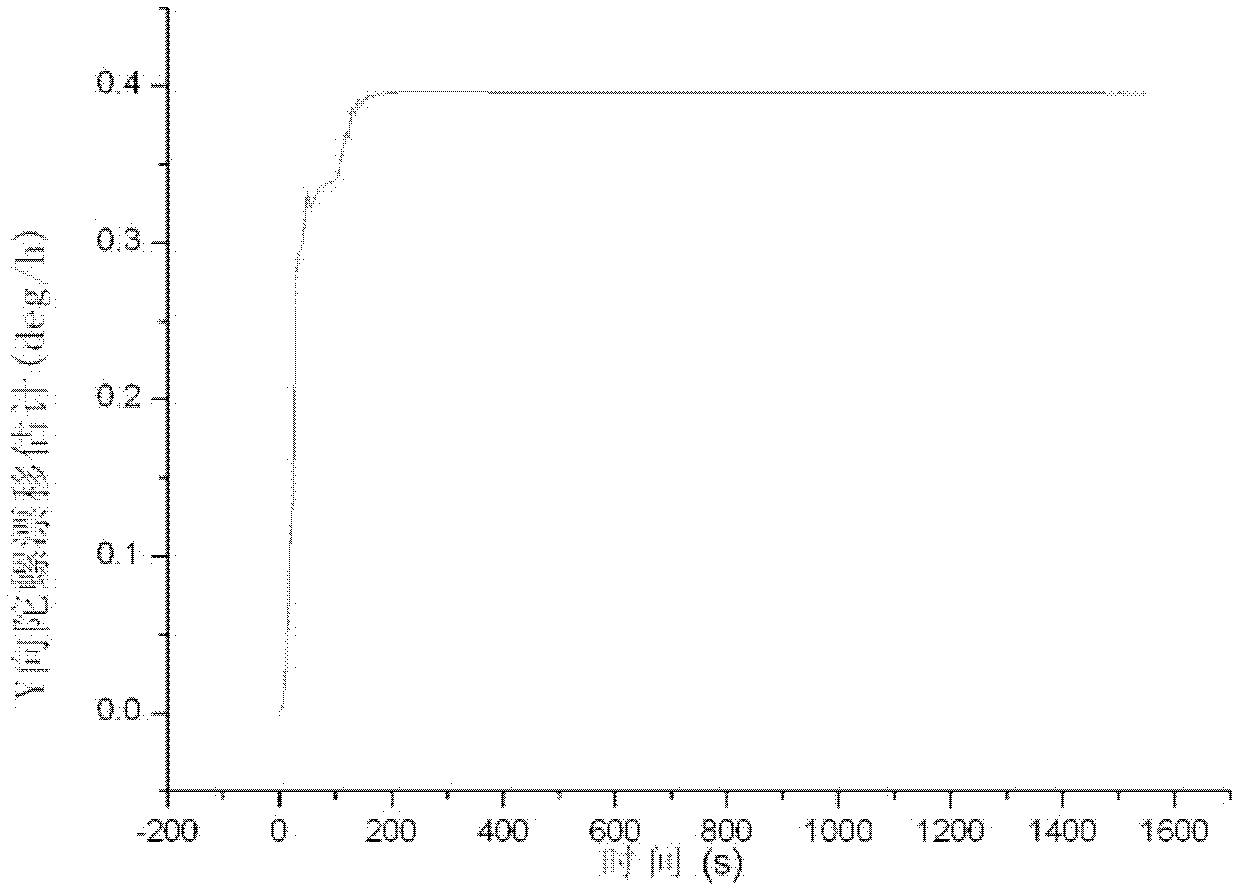

Method for testing dynamic random drifting of strap-down flexible gyroscope by aid of laser Doppler velocimeter

ActiveCN102607595ASpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesGyroscopeLaser Doppler vibrometer

The invention discloses a method for testing dynamic random drifting of a strap-down flexible gyroscope by the aid of a laser Doppler velocimeter, which belongs to the field of inertia technology. The method for testing dynamic random drifting of the strap-down flexible gyroscope by the aid of the laser Doppler velocimeter includes mounting the tested strap-down flexible gyroscope on a test car, and electrifying and preheating a flexible strap-down inertia unit until the flexible strap-down inertia unit is stable; synchronously acquiring data of the flexible strap-down inertia unit and data of the laser Doppler velocimeter; and keeping the test car fixed, and initially aligning fixed bases of two positions based on a course angle of 180 degrees by the aid of a Kalman filter; starting the test car, leading the car to start to run, and estimating for inertia / Doppler combined navigation for the full stroke. Accurate speed measurement of the laser Doppler velocimeter is used as observation information, random drifting errors of the flexible gyroscope in a vehicular dynamic environment are estimated by the Kalman filter, shortcomings that random drifting errors of a flexible gyroscope are only calibrated, tested and assessed by a multi-position method in a laboratory at present are overcome, and an auxiliary analysis means and an assessment basis for dynamic precision analysis of the flexible gyroscope and the flexible inertia unit are provided.

Owner:湖南率为控制科技有限公司

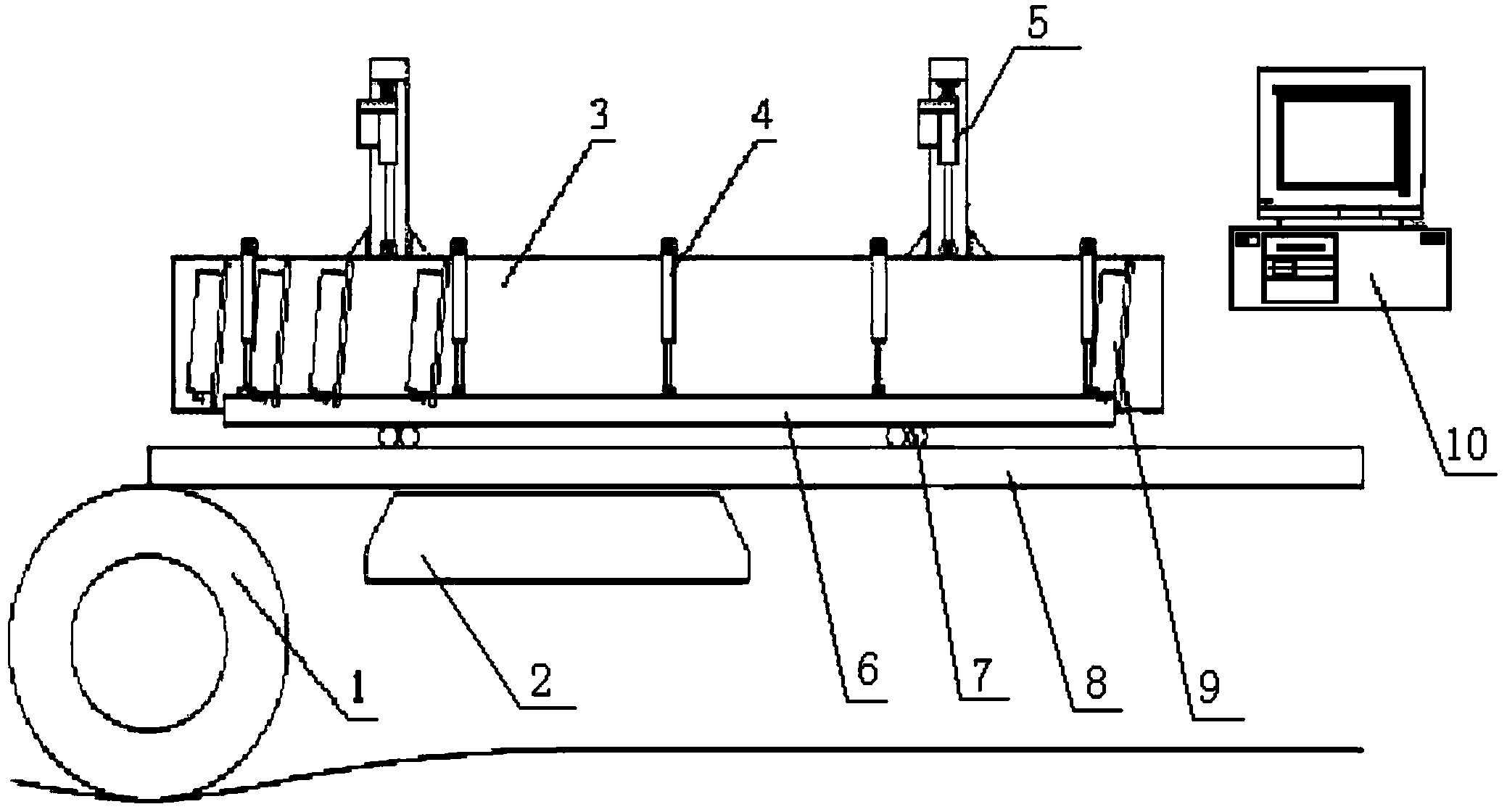

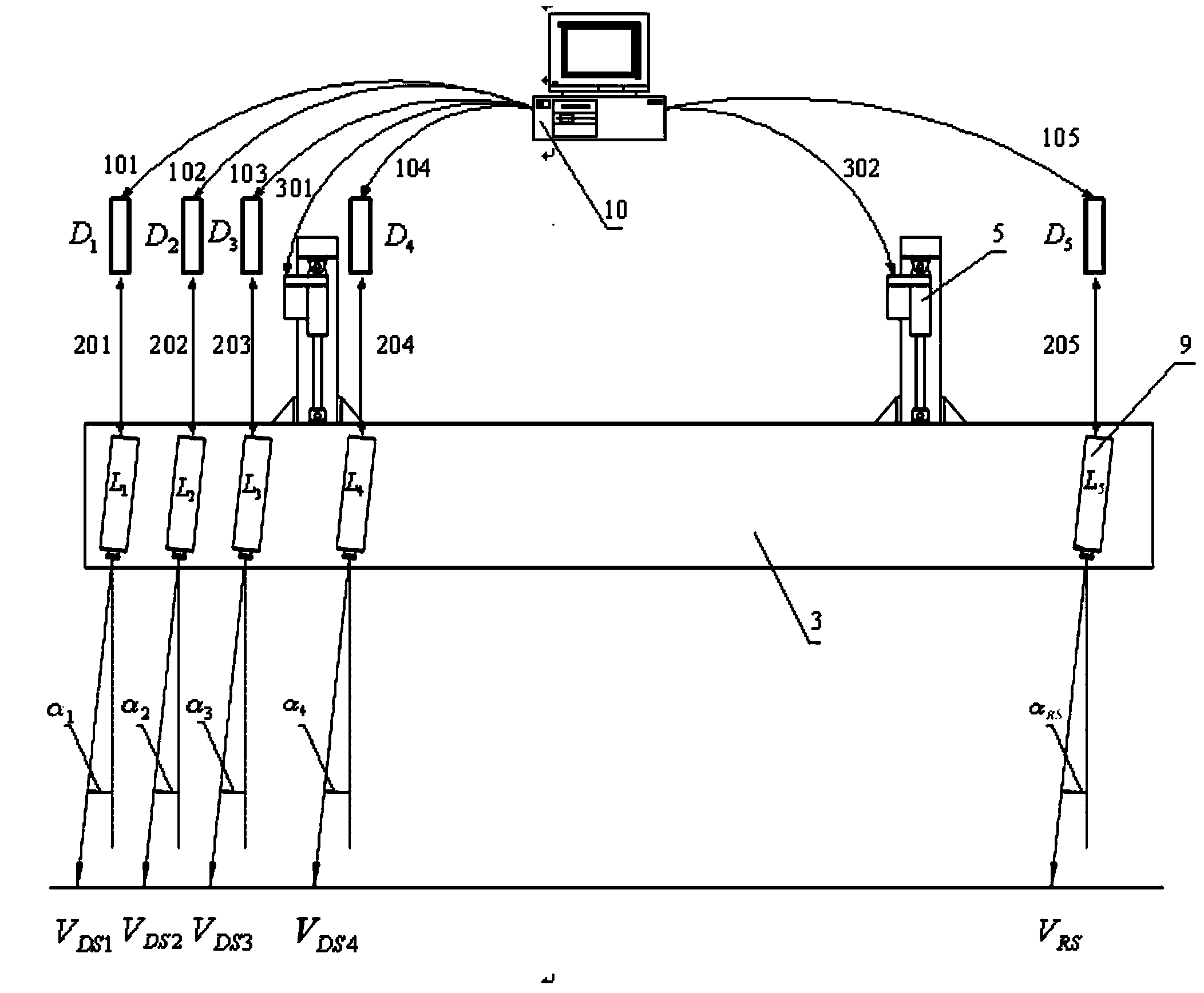

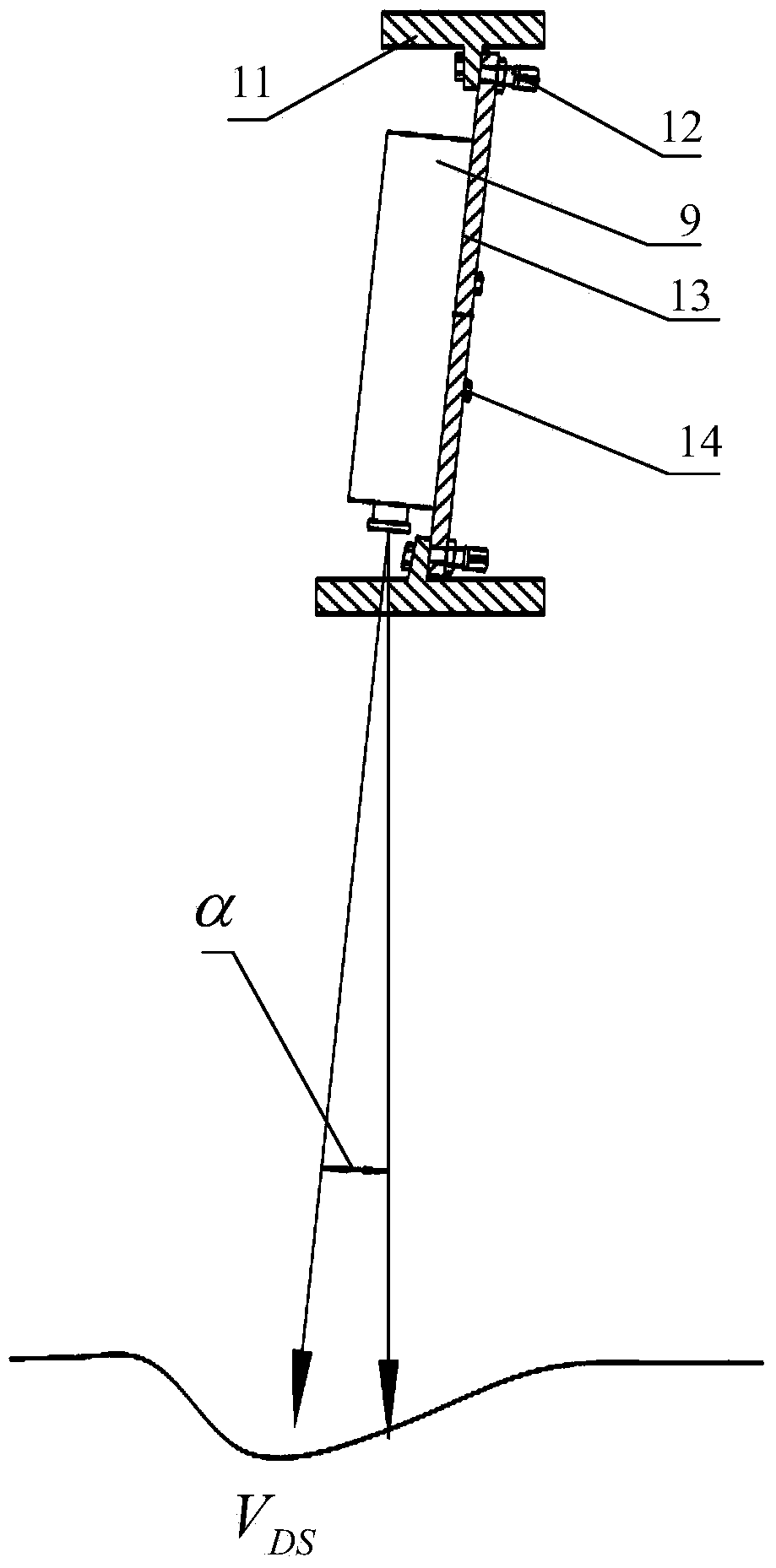

Laser beam parallelism adjustment system and laser beam parallelism adjustment method for road surface deflection measurement

The invention relates to the field of road surface deflection measurement, and in particular relates to a laser beam parallelism adjustment system and a laser beam parallelism adjustment method for the road surface deflection measurement. The system comprises a laser test common beam which is arranged on a movable steel beam frame; the movable steel beam frame is arranged on a linear guide rail platform; the laser test common beam is provided with more than three laser velocimeters; each laser velocimeter is connected with a controller by a speed signal acquisition device; and the system also comprises a servo control device used for controlling the laser test common beam to make vertical uniform motion. The system can be used for judging whether laser beams of the laser velocimeters are parallel or not. The system also comprises a laser beam included angle adjustment device, so that the included angles between the laser velocimeters and the vertical direction can be adjusted by the laser beam included angle adjustment device. After the system is adopted, the actual installation angle value of a reference laser velocimeter can be rapidly and accurately obtained when a deflection test vehicle travels at the normal speed.

Owner:BEIJING LUXING NEW ROAD TECH

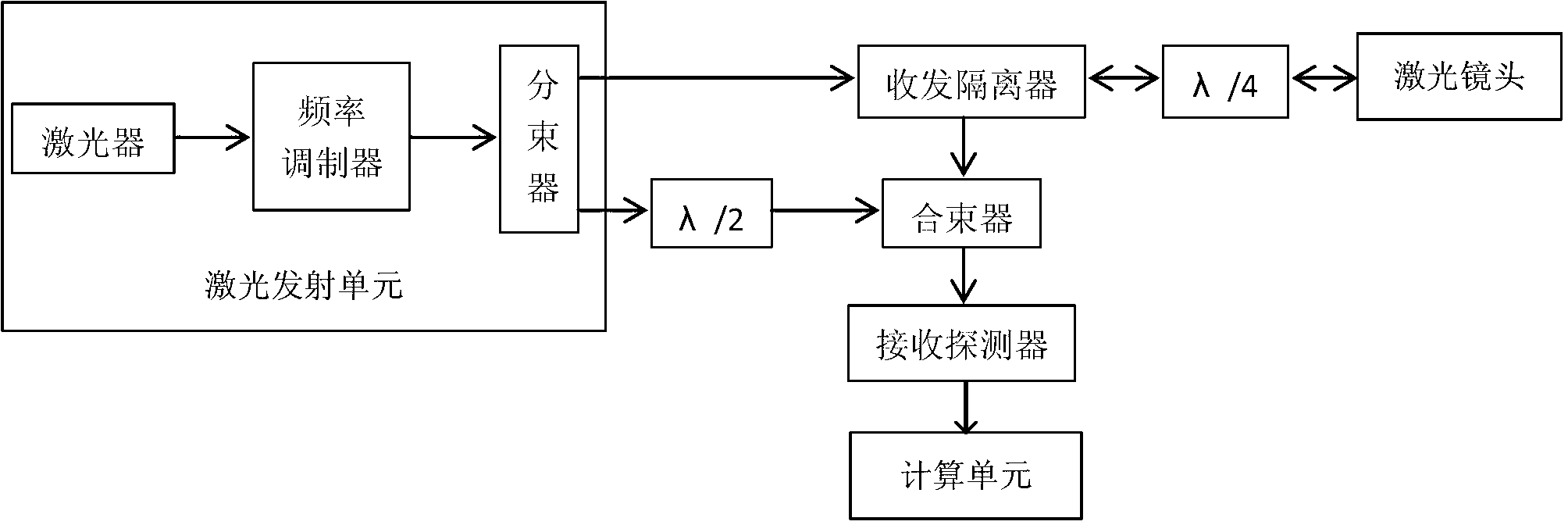

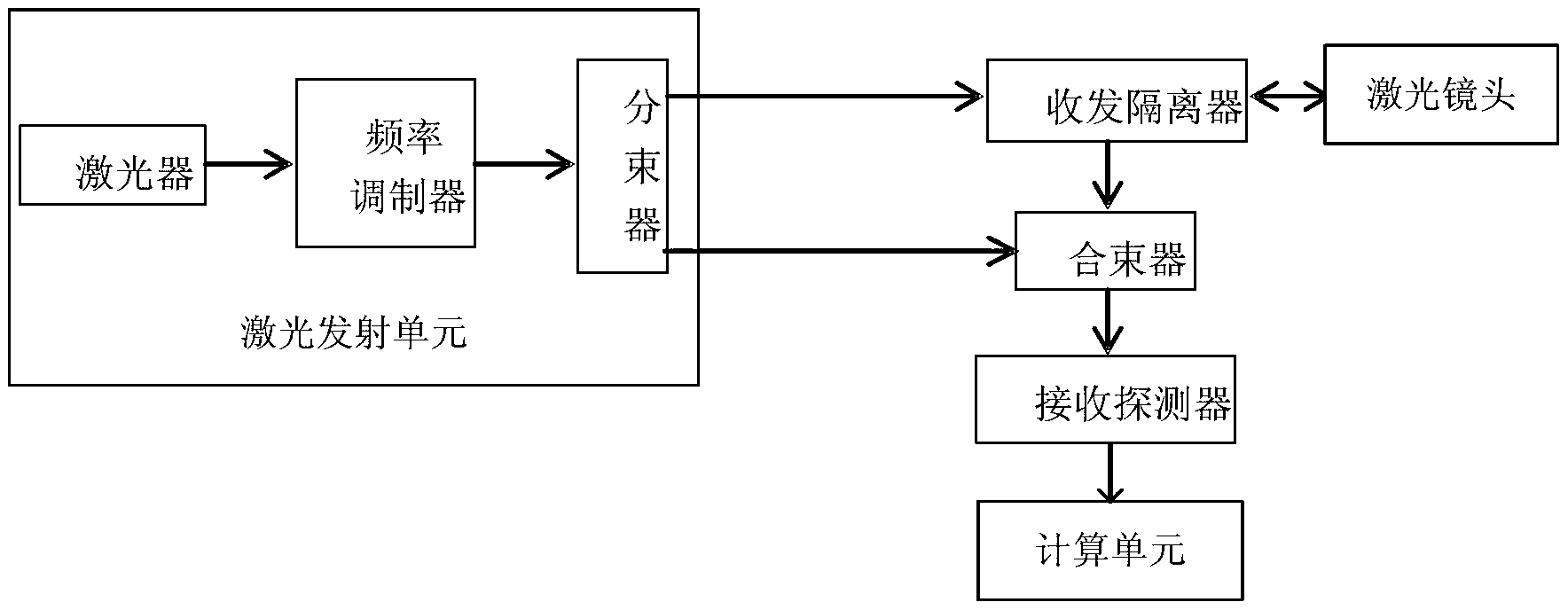

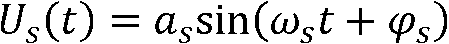

Laser Doppler velocity-measuring system with all-optical fiber light-frequency modulation

InactiveCN102854511AReduce power consumptionReduce volumeFluid speed measurementElectromagnetic wave reradiationFiberDoppler velocity

The invention discloses a laser Doppler velocity-measuring system with all-optical fiber light-frequency modulation. The system comprises a laser emission unit, a transceiving isolator, a laser lens, a beam combiner, a receiving detector and a computation unit, and the all optical functional units or devices are connected mutually by optical fibers. By using the system, the detection sensitivity of a laser Doppler velocity-measuring technology reaches quantum noise theory limit, and an optical system of the laser Doppler velocity-measuring technology is upgraded completely. A laser Doppler velocity-measuring meter using a new technology has the advantages that the power consumption is lower, the volume is smaller, the weight is lighter, the structure layout is more reasonable, the construction is more convenient, a transmitting lens and a receiving lens become one, no sensitiveness to impact vibration and high-low temperature changes exists, and requirement for cleanness degree of environment is low.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

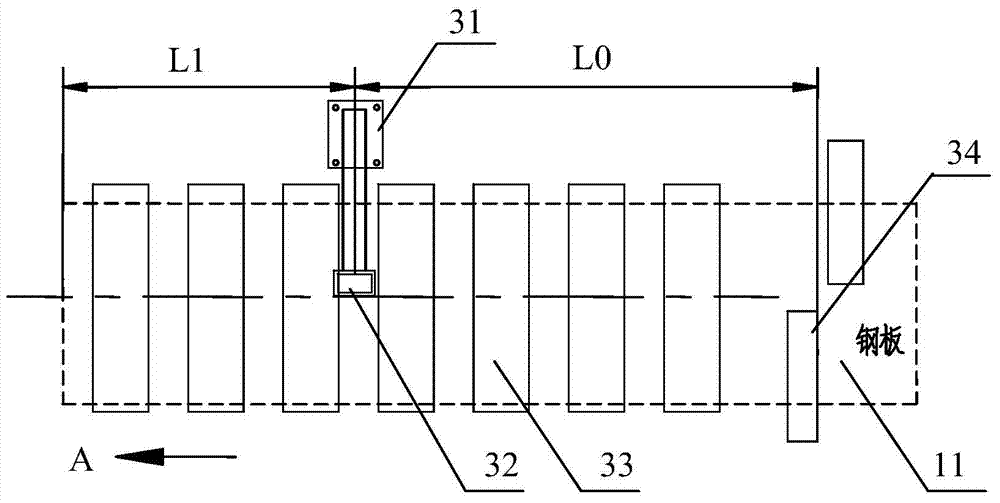

Method for measuring length of steel plate

InactiveCN104515471AHigh precisionReal-time running speed measuredUsing optical meansProduction lineSheet steel

The invention discloses a method for measuring length of a steel plate, relates to end cutting technology of a finishing line of a thick plate production line and solves the problem that existing steel plates are low in sectional cutting accuracy. The method includes enabling an end cutting conveying roller way to start running, enabling the steel plate to move forwards, enabling a laser velocimeter mounted at an outlet of an end cutting shear and at a position of L0 away from a cutting edge of a lower shear blade of the end cutting shear to emit laser, and transmitting feedback signals when the laser irradiates the steel plate to a PLC (programmable logic controller); enabling the PLC to start performing length measuring detection on the steel plate; comparing L with target length Lm preset in the PLC; when L is equal to Lm, enabling the conveying roller way to stop running, enabling the steel plate to stop moving, starting the end cutting shear, and automatically cutting the steel plate at a position of Lm; if the last section is not cut, cutting a next section, and continuing to execute the above steps until the last section is cut. In the method, the laser velocimeter is utilized to measure length of the steel plate, so that accuracy in sectional cutting of the steel plate is improved effectively, yield is increased, and cutting efficiency is improved while labor intensity is lowered.

Owner:BAOSHAN IRON & STEEL CO LTD +1

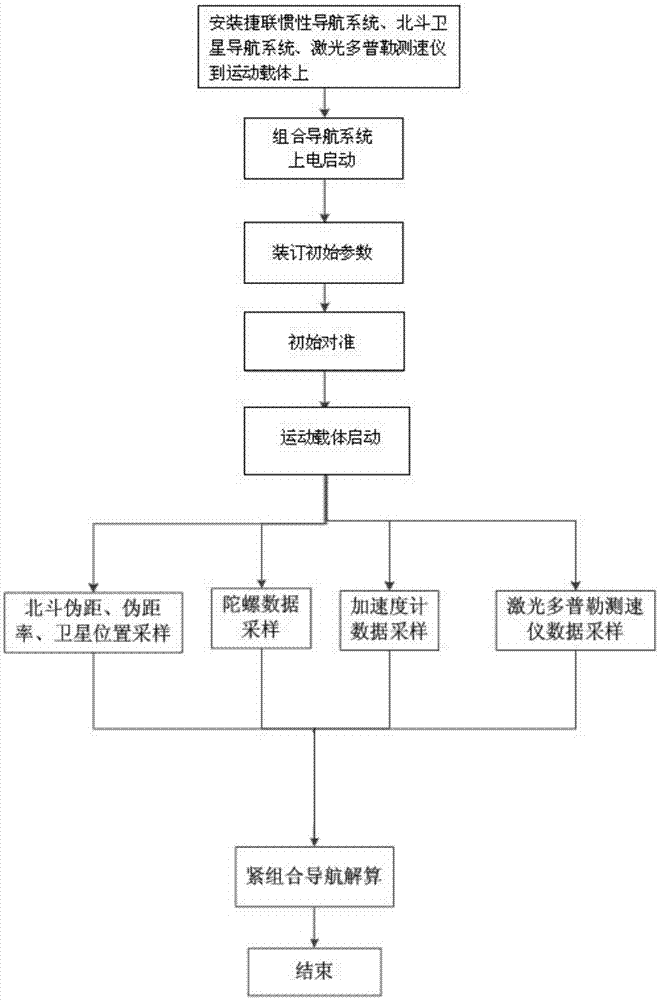

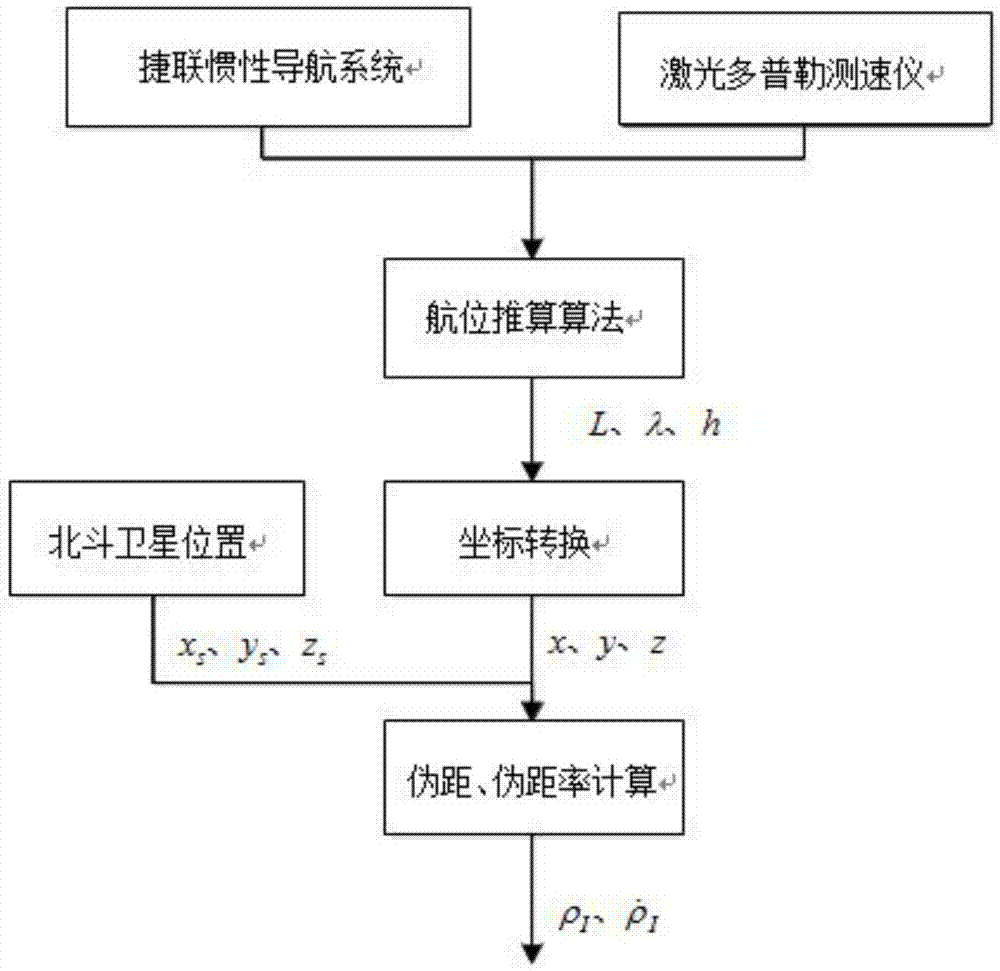

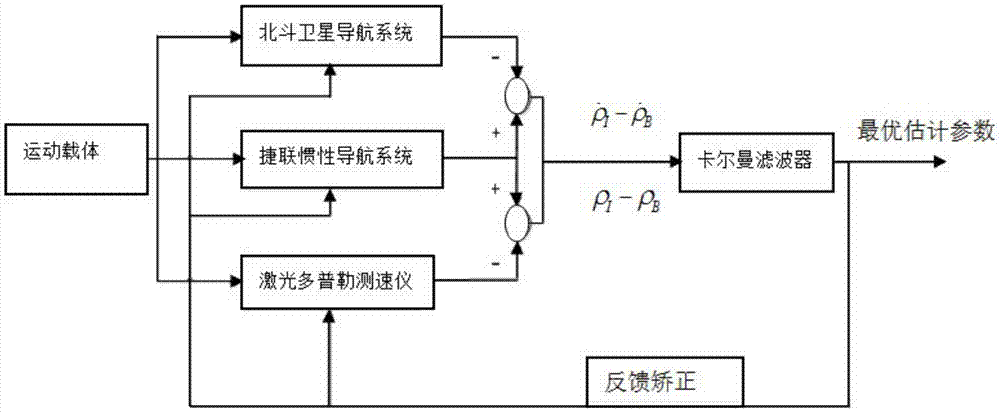

Tight combination method for calculating pseudo range/pseudo range rate by using Doppler velocimeter

ActiveCN107015259ARealize high-precision navigationNavigation by speed/acceleration measurementsSatellite radio beaconingNavigation systemInertial navigation system

Owner:中联天通科技(北京)有限公司

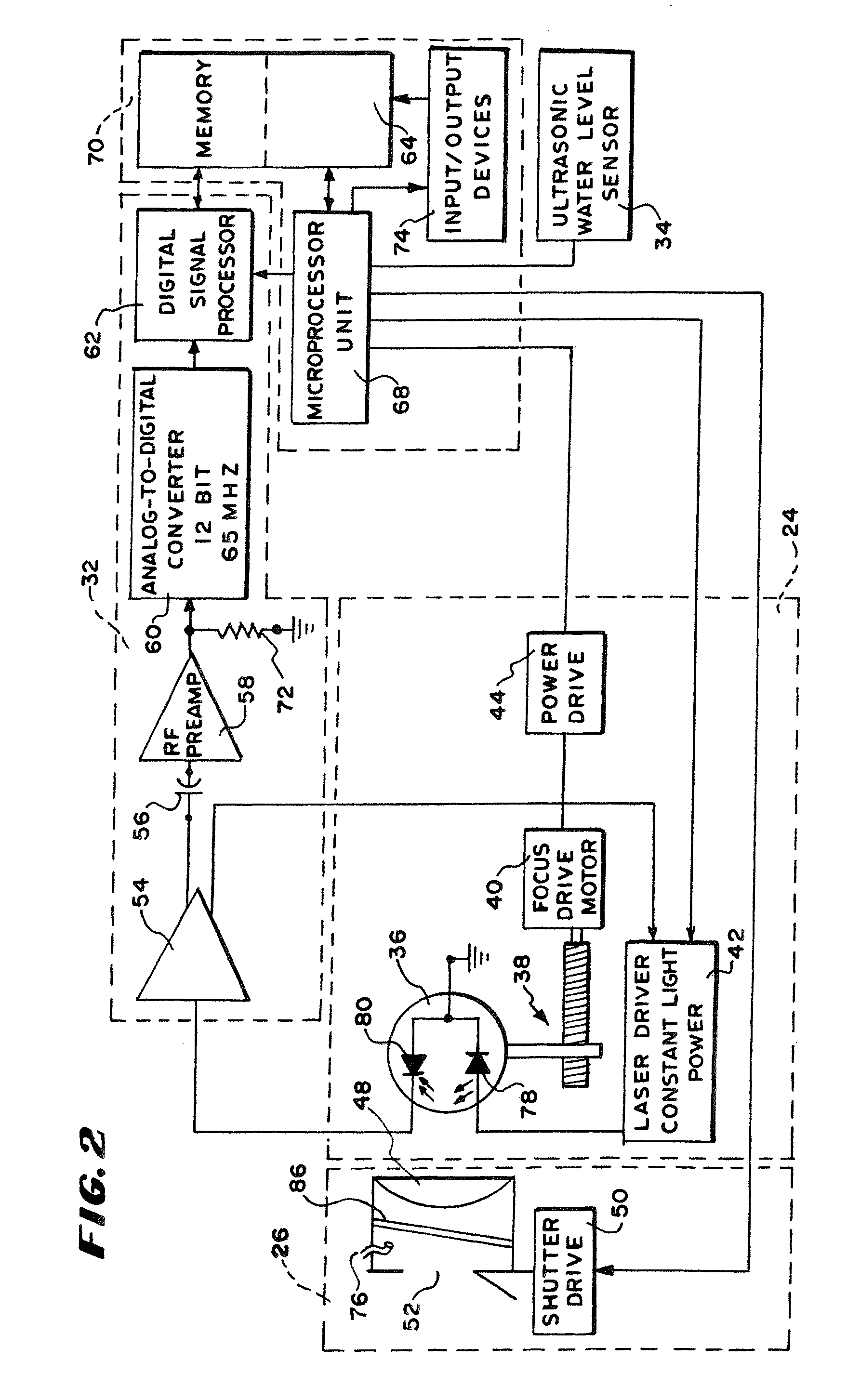

Velocity measuring system

ActiveUS8339584B2High resolutionHigh precisionFluid speed measurementDevices using optical meansData segmentSignal-to-quantization-noise ratio

A laser Doppler velocimeter uses self-mixing amplification of backreflections from scatterers below the surface of a flow.A time domain signal is divided into segments that are roughly equal to a transit time of particles through a focus of a laser beam. The segments are connected to a frequency domain through the use of an FFT algorithm to produce frequency domain data segments. Signal-to-noise ratio is enhanced through signal processing techniques using the segments to produce a final enhanced signal spectrum.

Owner:TELEDYNE

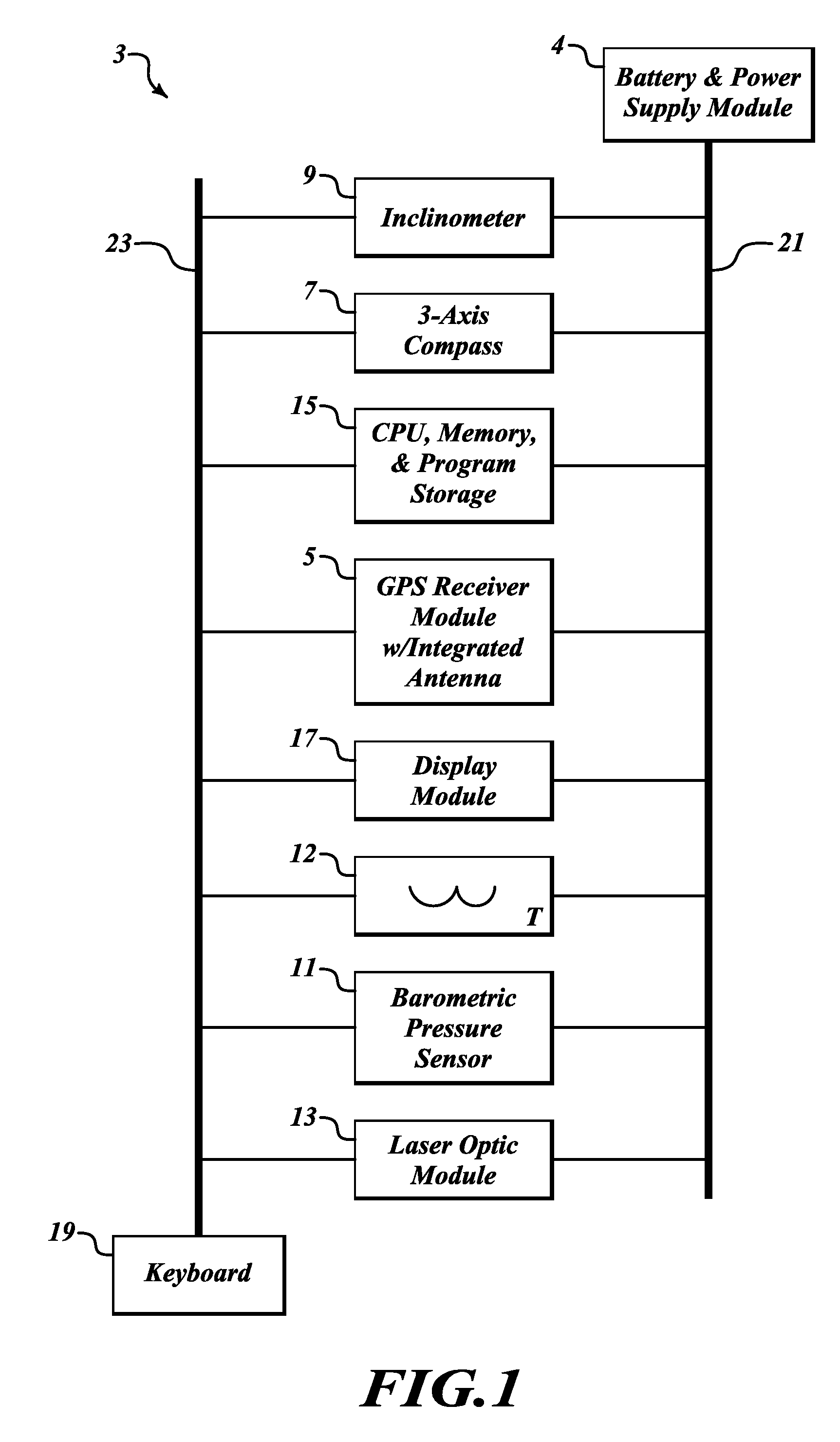

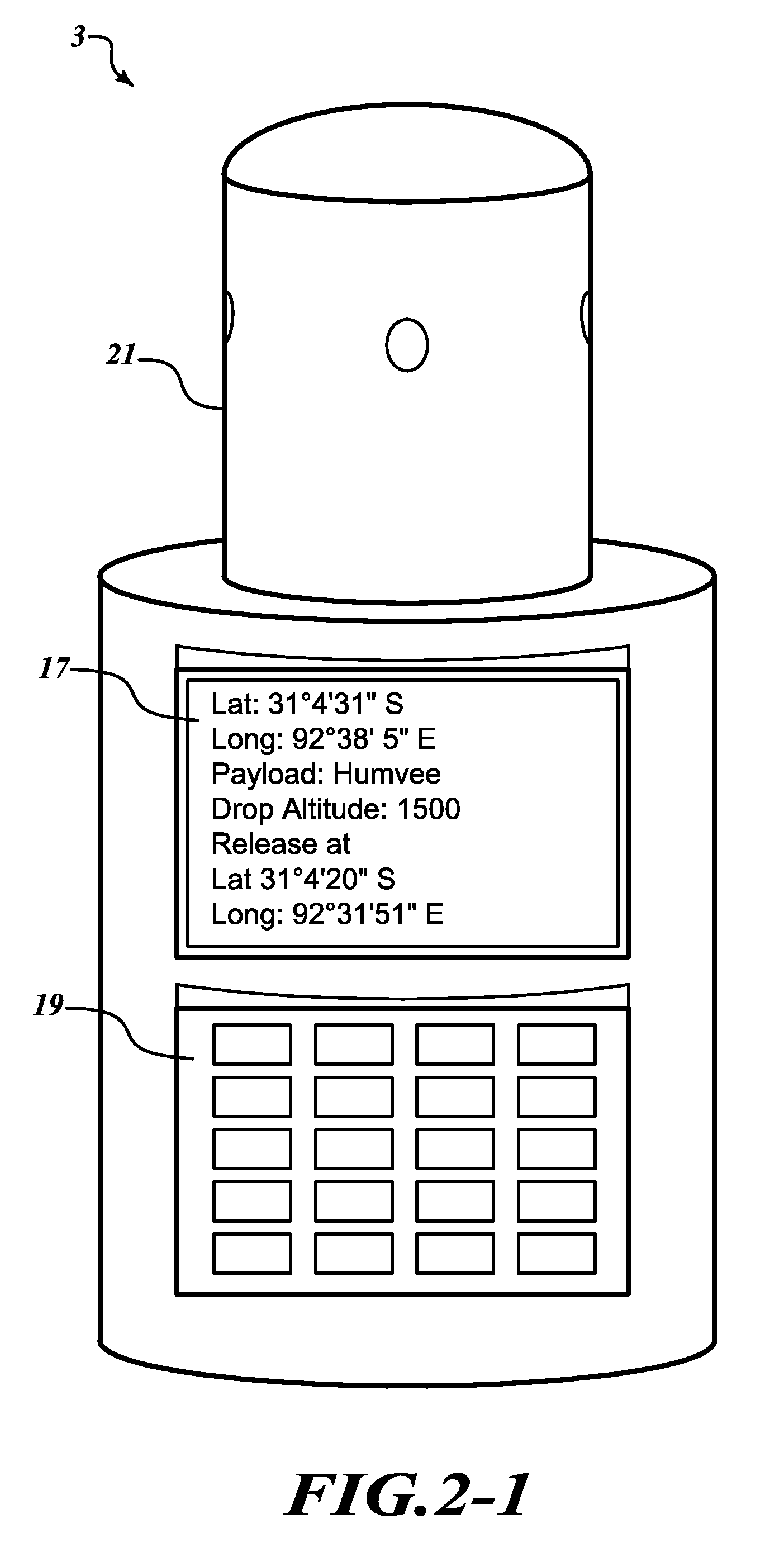

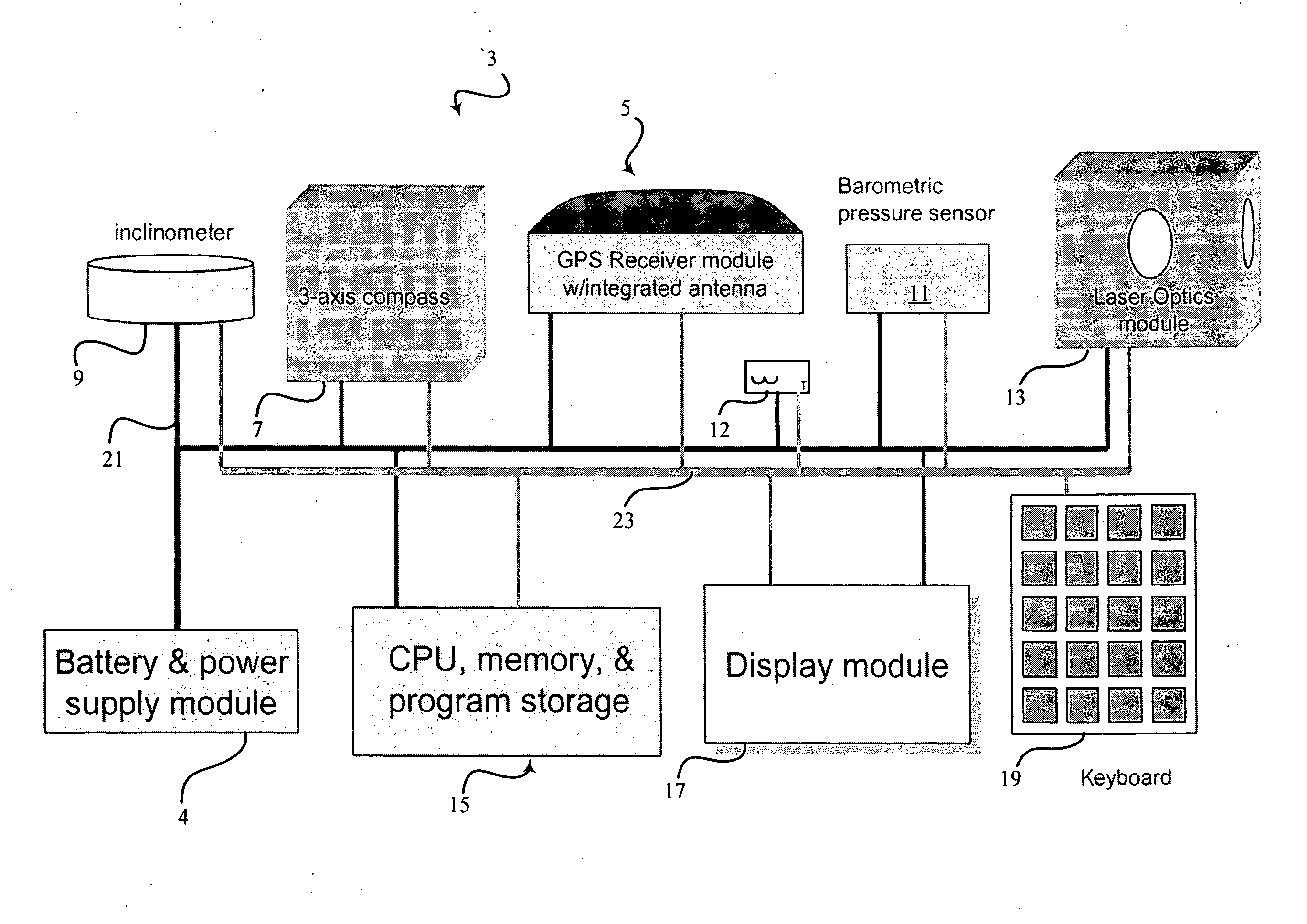

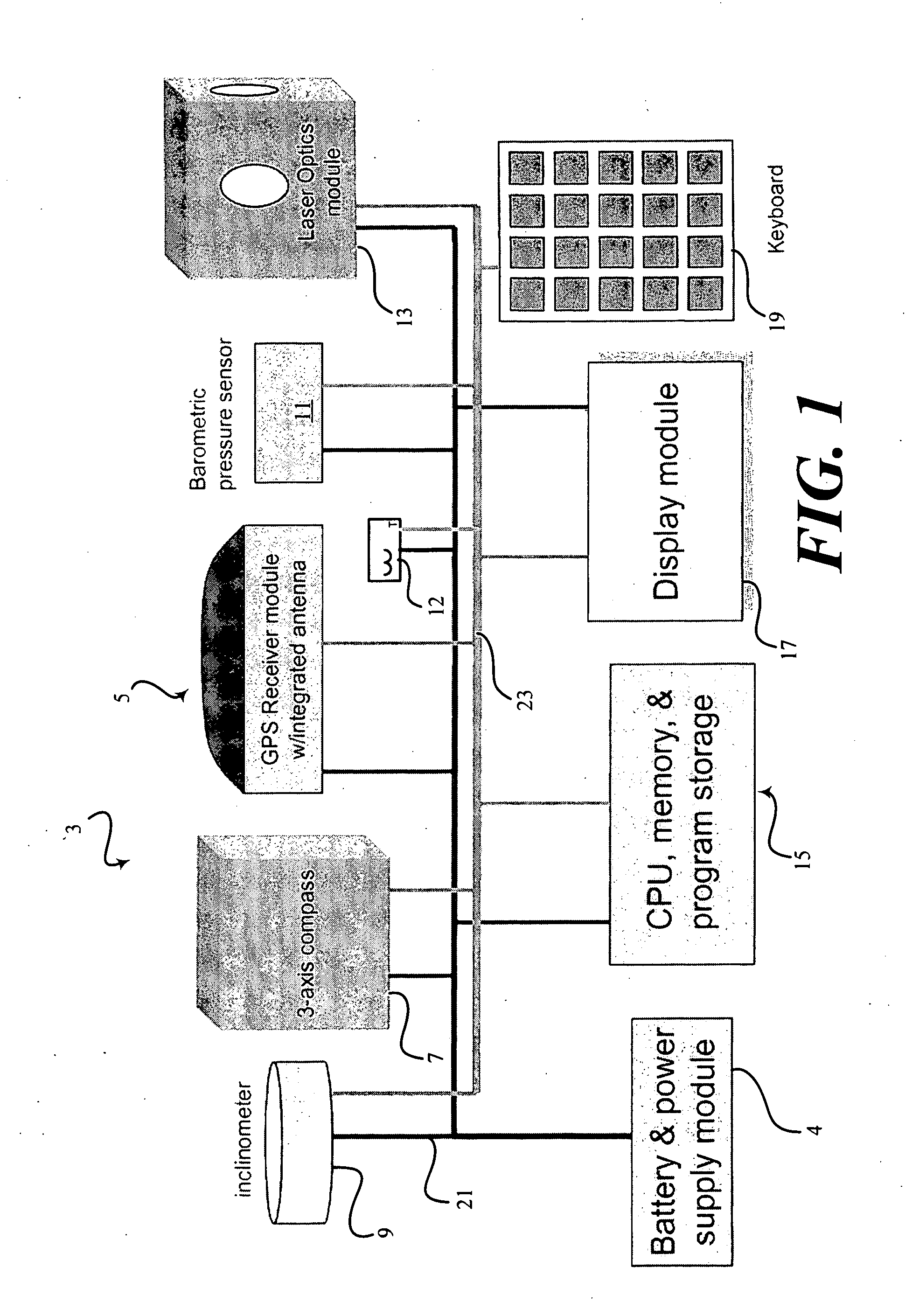

Winds aloft profiler

InactiveUS20100004913A1Input/output for user-computer interactionCathode-ray tube indicatorsTerrainWind profiler

A platform for a handheld wind profiler includes a housing containing a three-axis magnetic compass module generating a compass signal, including the orientation of the housing relative to magnetic north at a time. A two-axis inclinometer module generates a inclinometer signal including the orientation of the housing relative to a horizontal plane at the time. A GPS module generating a GPS signal indicating a time and position solution including a terrain position of the housing based upon the time. A processor receives a first velocimeter signal at the time from at least one laser Doppler velocimeter. The velocimeter signal includes a first radial velocity of a first wind-borne aerosol and a first orientation of the at least one laser Doppler velocimeter relative to the housing. The processor resolves the first velocimeter signal to determine an orientation of the at least one laser Doppler velocimeter relative to the terrain position.

Owner:HONEYWELL INT INC

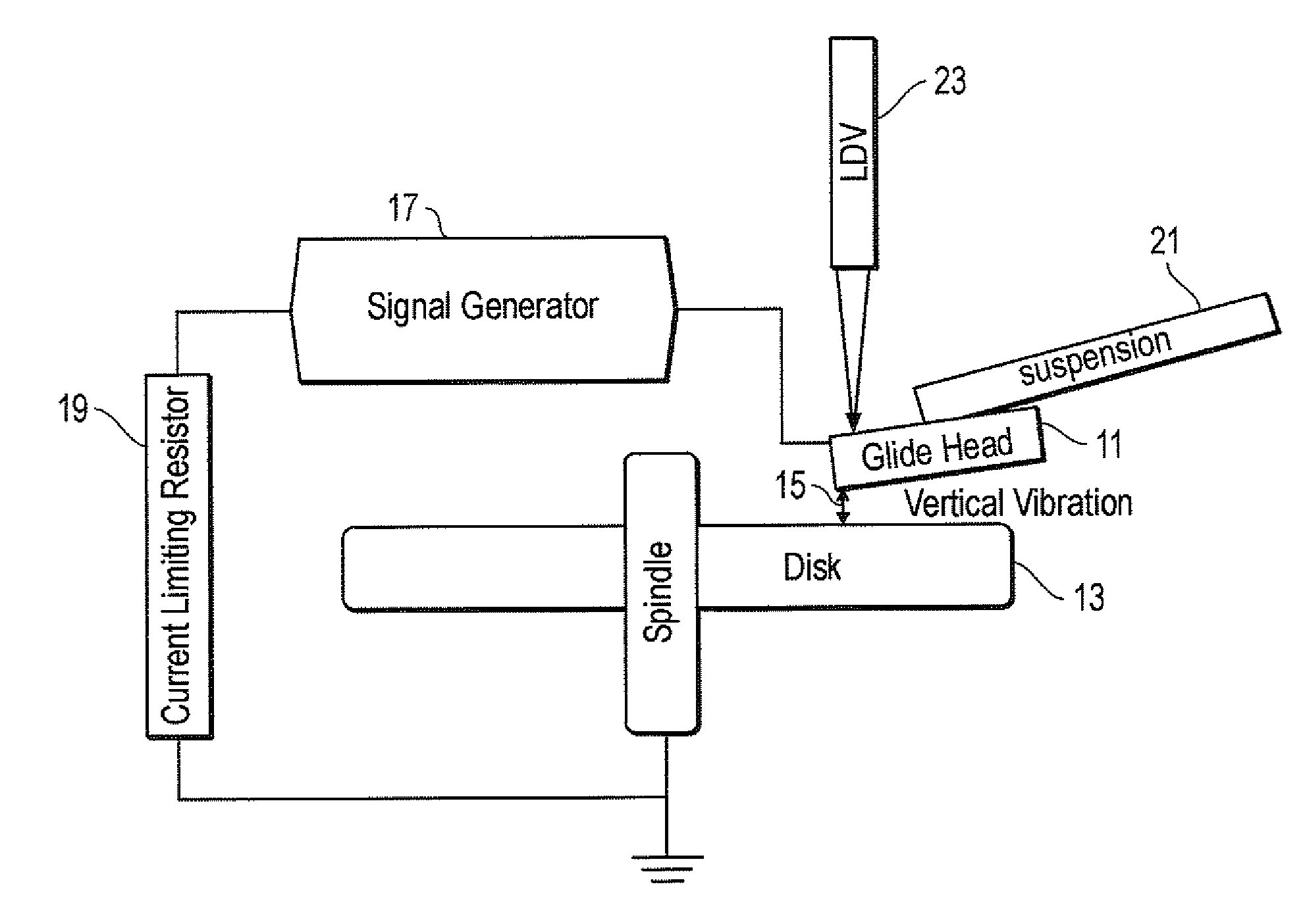

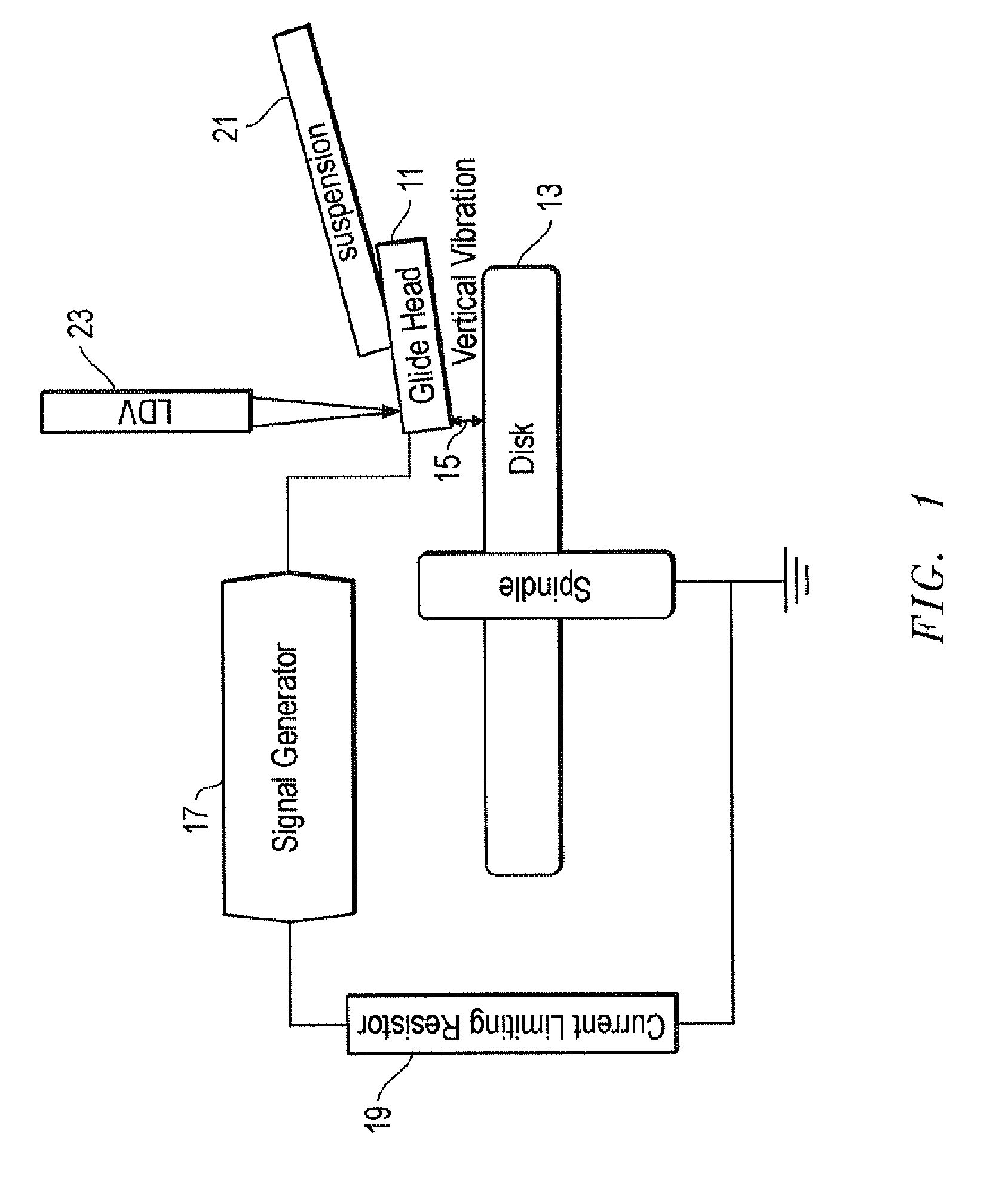

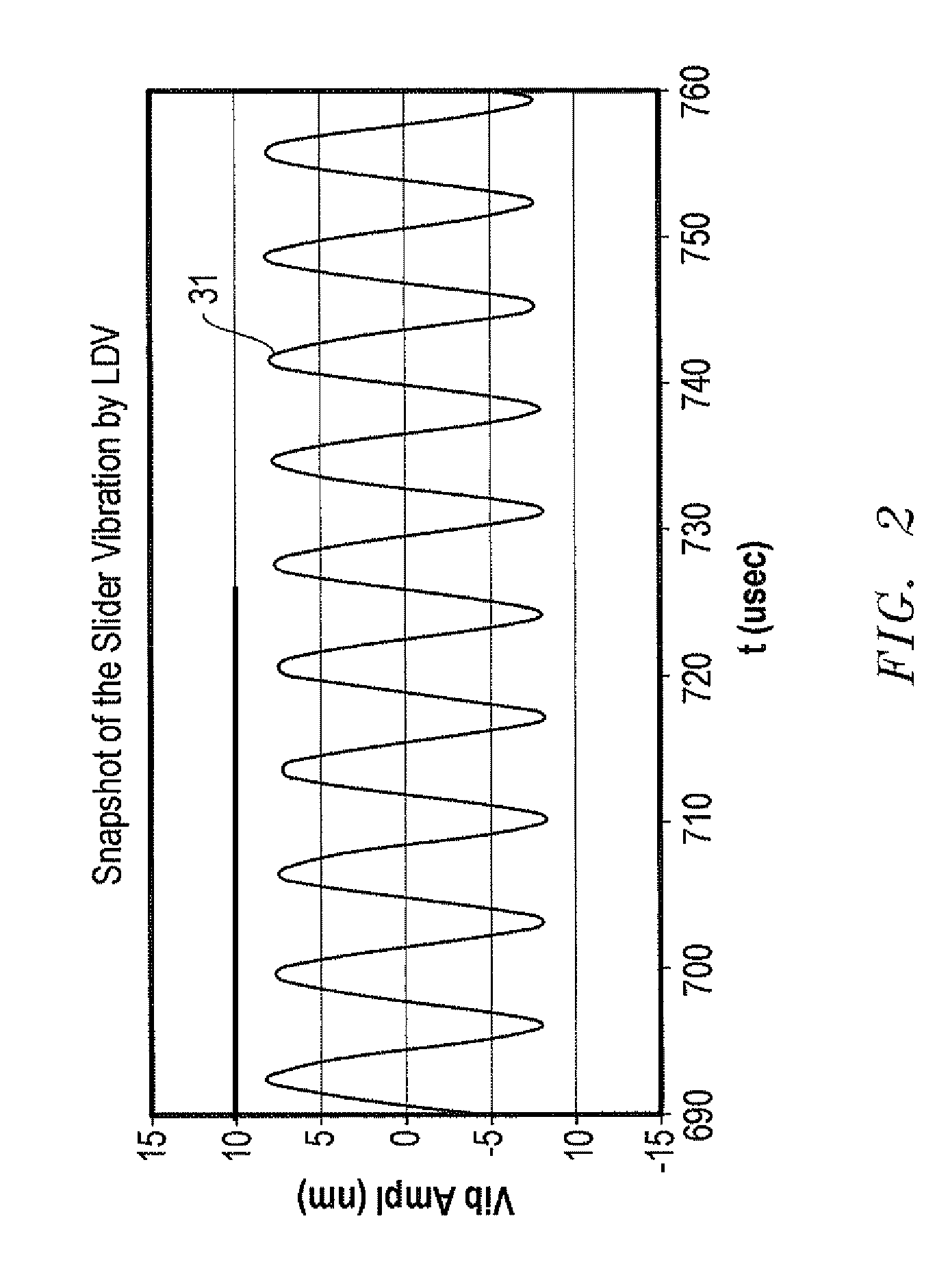

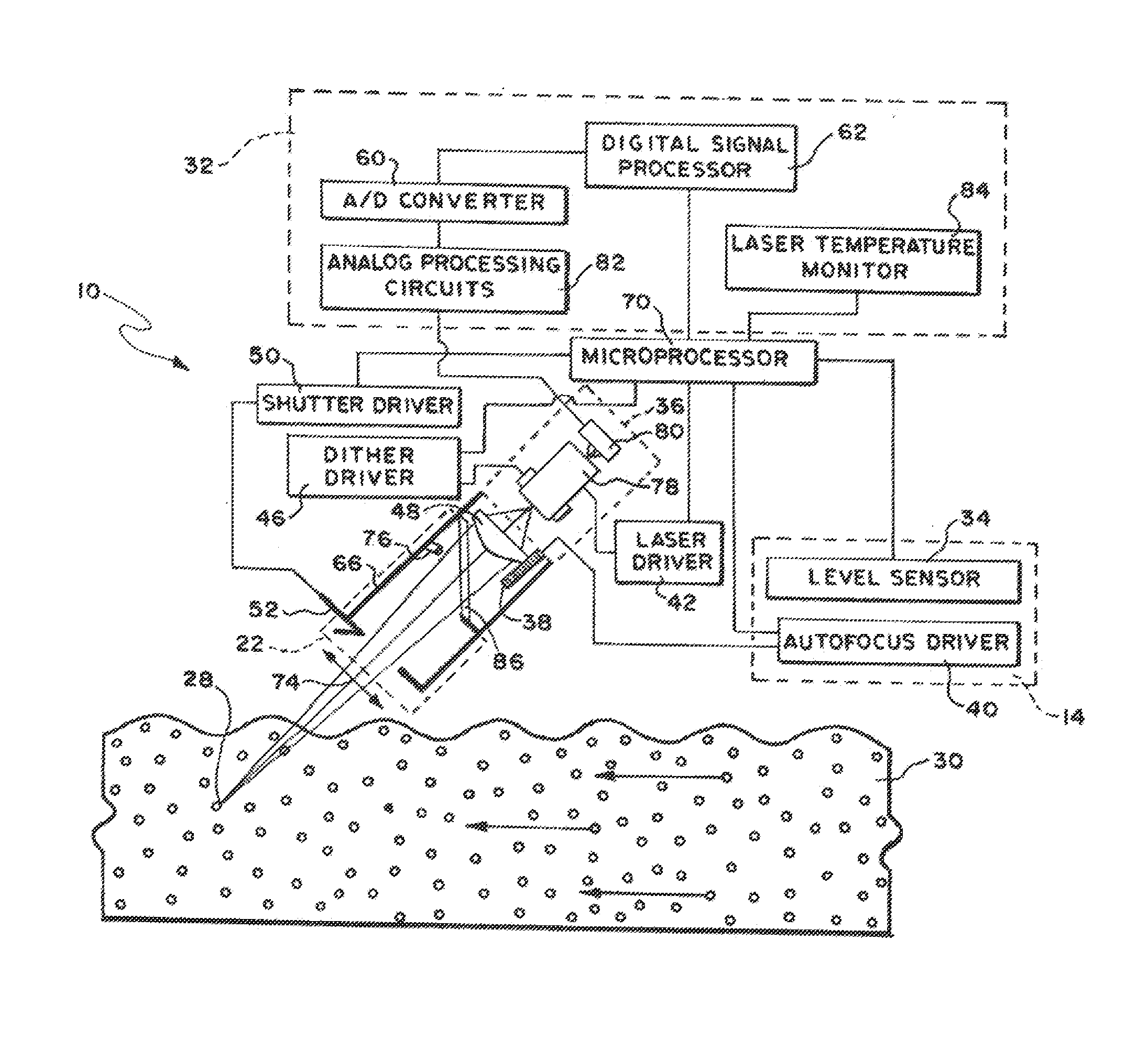

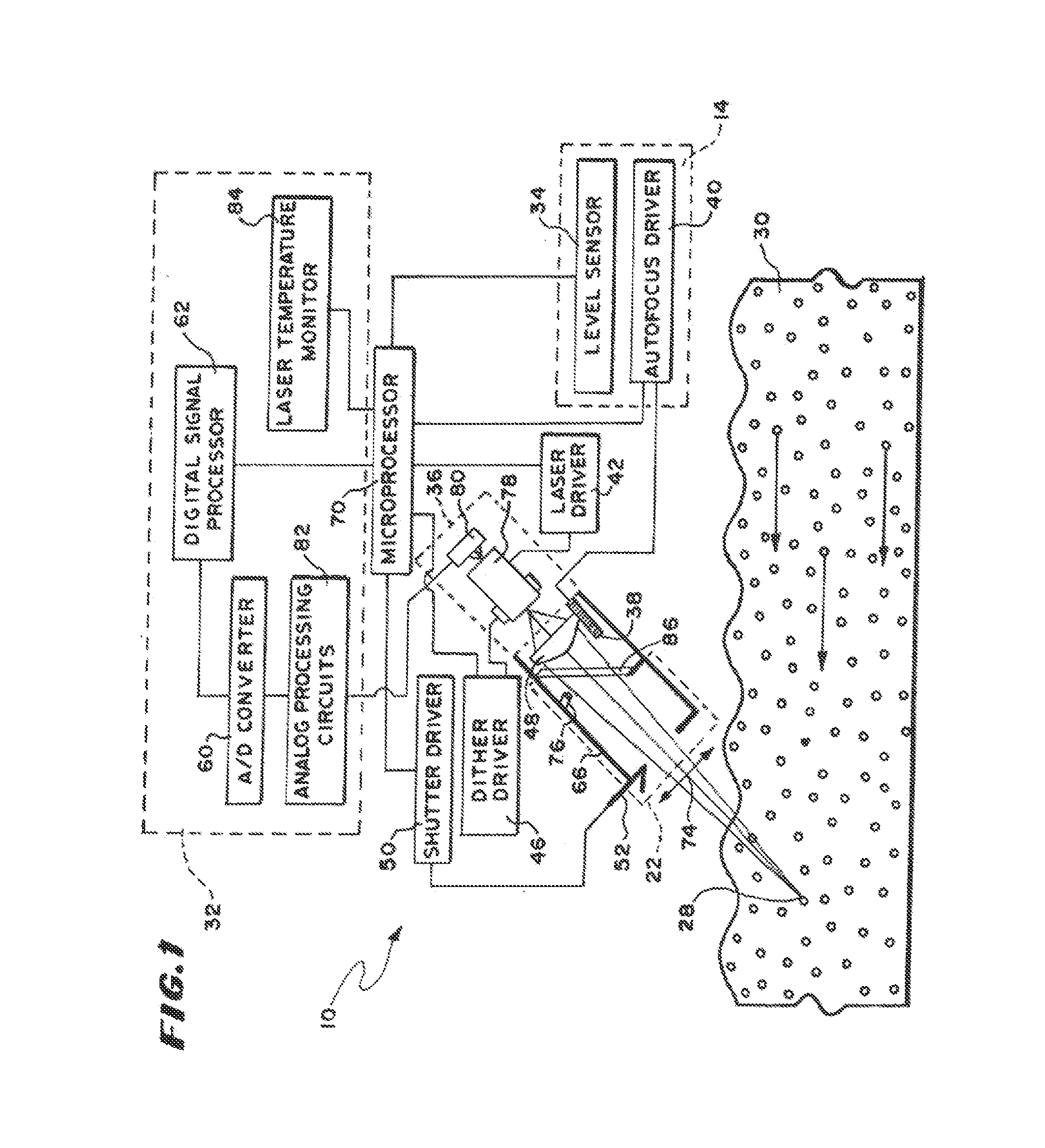

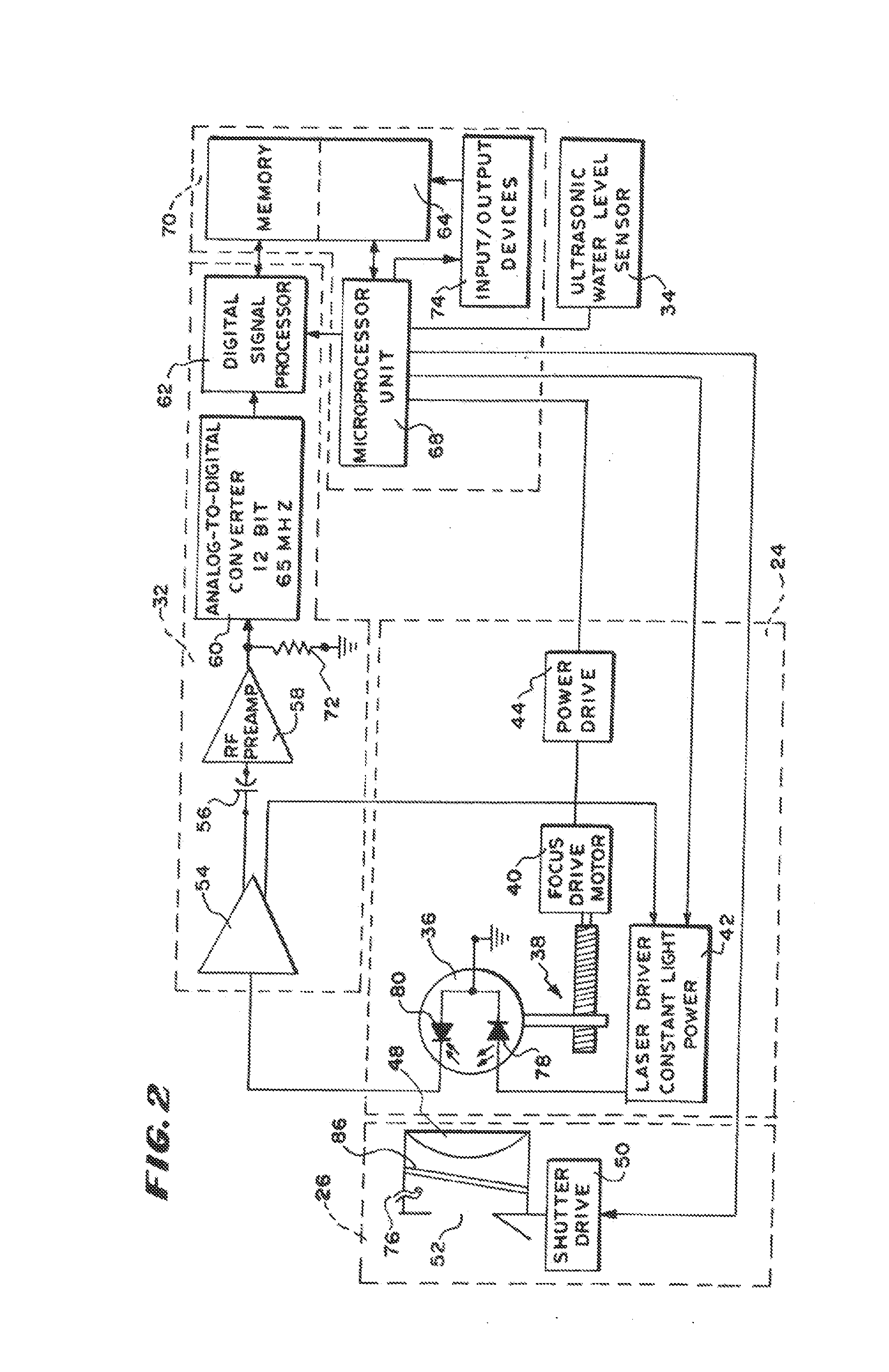

System, method and apparatus for direct head-disk clearance measurement by slider vibration and fly height calibration

InactiveUS7724462B2Accurate CalibrationDriving/moving recording headsRecord information storageVibration amplitudeCapacitance

A method models and calibrates the fly height of a slider above the disk for disk drives. The calibration scheme uses the Wallace spacing loss equation and laser doppler velocimetry to predict fly height and detect the actual fly height of the slider. The slider is vibrated at selected resonances, such as by capacitive coupling to the disk, and the fly height is gradually reduced. In one version, contact between the slider and disk may be detected using an arm electronics sensor. The amplitude of mean-to-peak, vibration detection is used as an indication of the actual fly height and to calibrate the modeled fly height.

Owner:WESTERN DIGITAL TECH INC

Velocity Measuring System

ActiveUS20130215411A1High resolution and precisionAvoid prolonged mode-hop laser instabilityDevices using optical meansFluid speed measurementTime domainData segment

A laser Doppler velocimeter uses self-mixing amplification of backreflections from scatterers below the surface of a flow. A time domain signal is divided into segments that are roughly equal to a transit time of particles through a focus of a laser beam. The segments are connected to a frequency domain through the use of an FFT algorithm to produce frequency domain data segments. Signal-to-noise ratio is enhanced through signal processing techniques using the segments to produce a final enhanced signal spectrum.

Owner:TELEDYNE

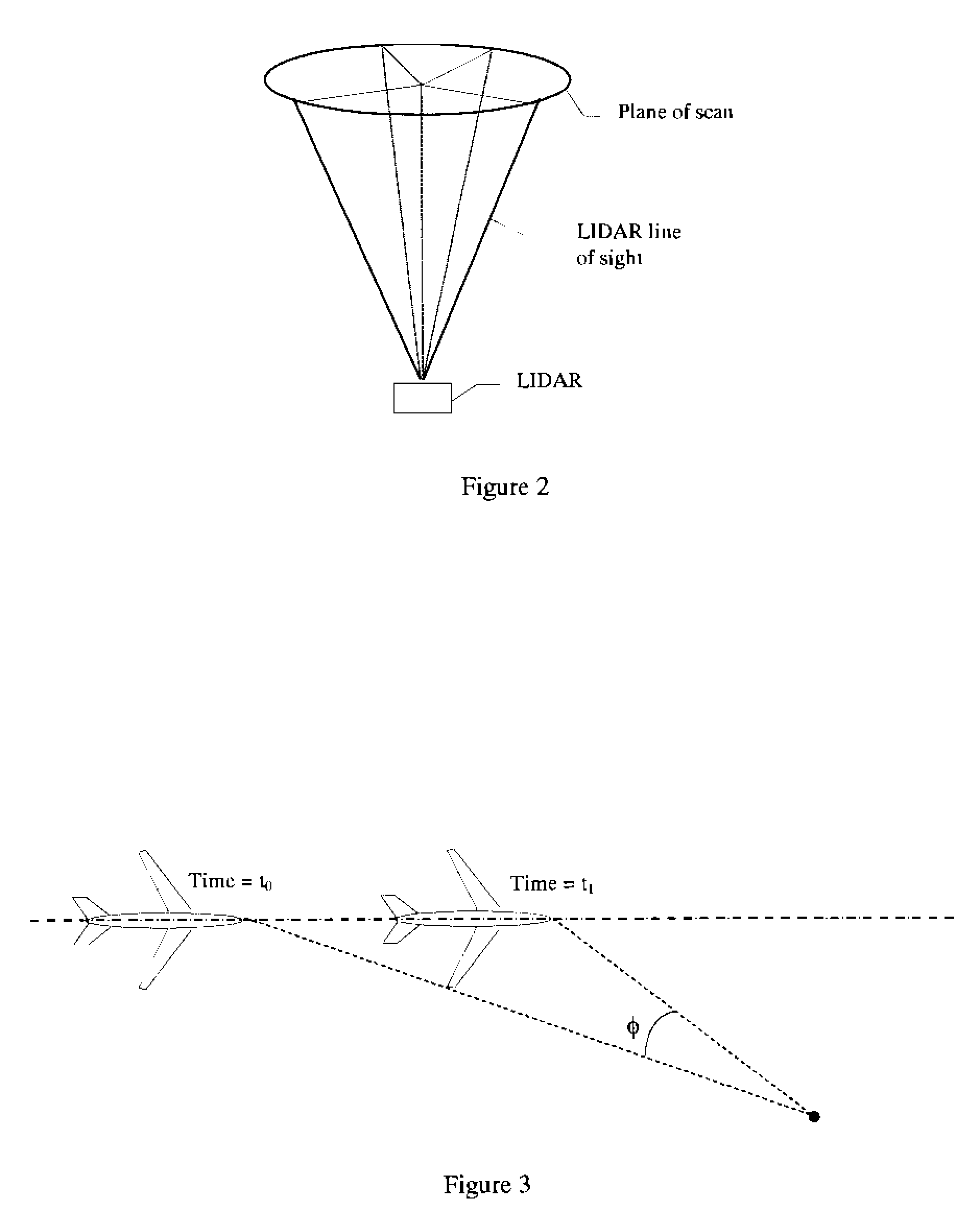

Winds aloft profiling system

An airborne wind profiler for an aloft aircraft includes a system bus for receiving a GPS signal including a time and position solution and an attitude signal representing heading, roll, pitch, and yaw of the aircraft. An optical module includes at least one laser Doppler velocimer including an mount allowing the at least one laser Doppler velocimeter to articulate in at least two axes, thereby to orient the laser Doppler velocimeter below a horizon to generate at least one first velocimeter signal. The velocimeter signal includes at least one first radial velocity of a first wind-borne aerosol and a first orientation of the at least one laser Doppler velocimeter relative to the aircraft. A processor module receives the first velocimer signal at the time from at least one laser Doppler velocimeter.

Owner:HONEYWELL INT INC

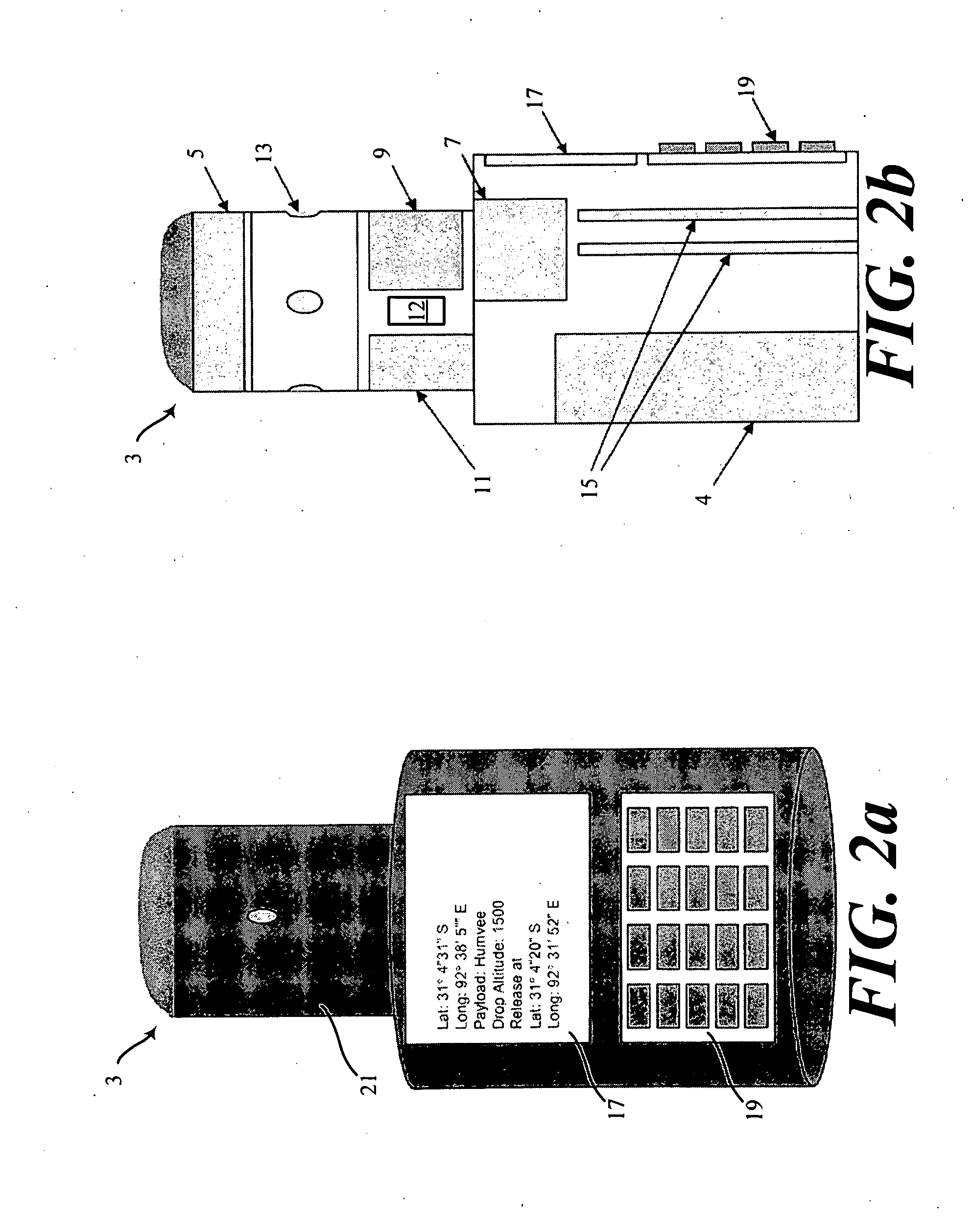

Laser pumped compact acoustic sensor system

InactiveUS7113447B1Transducer detailsSubsonic/sonic/ultrasonic wave measurementAcoustic energyDisplay device

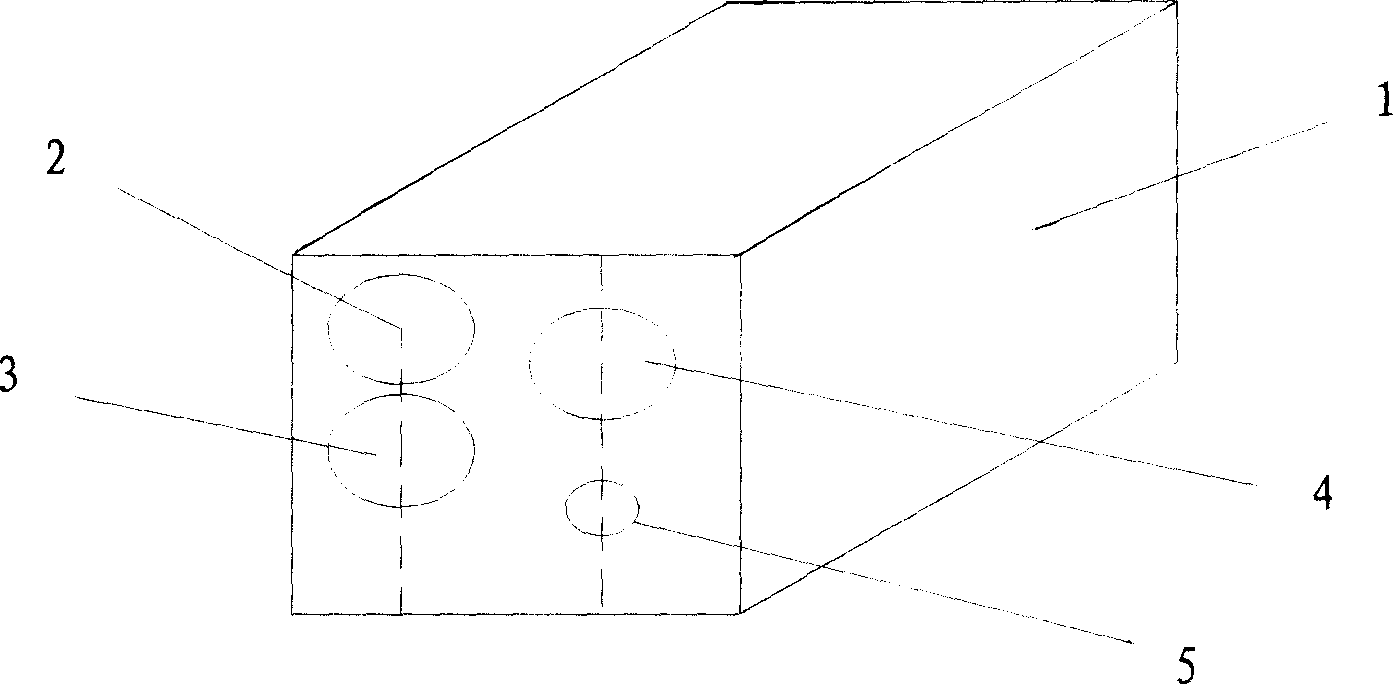

An acoustic transducer system for acoustic signals in water has at least one hollow spherically-shaped shell for vibrating in response to acoustic signals impinging from the water. The hollow spherically-shaped shell has one or more portions that are reflective of impinging radiation, and a resilient matrix in contact with the water resiliently supports the responsive hollow shell. A laser Doppler velocimeter transmits radiation onto the reflective portion (portions) and receives reflected radiation from the reflective portion (portions). The reflected radiation generates signals in the laser Doppler velocimeter that are representative of the acoustic signals from the water medium. A computer receives the representative signals from the laser Doppler velocimeter and displays them on an interconnected display to determine direction and range to a target. The acoustic signals can originate from the target or can be reflected portions of acoustic energy transmitted from an acoustic projector.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

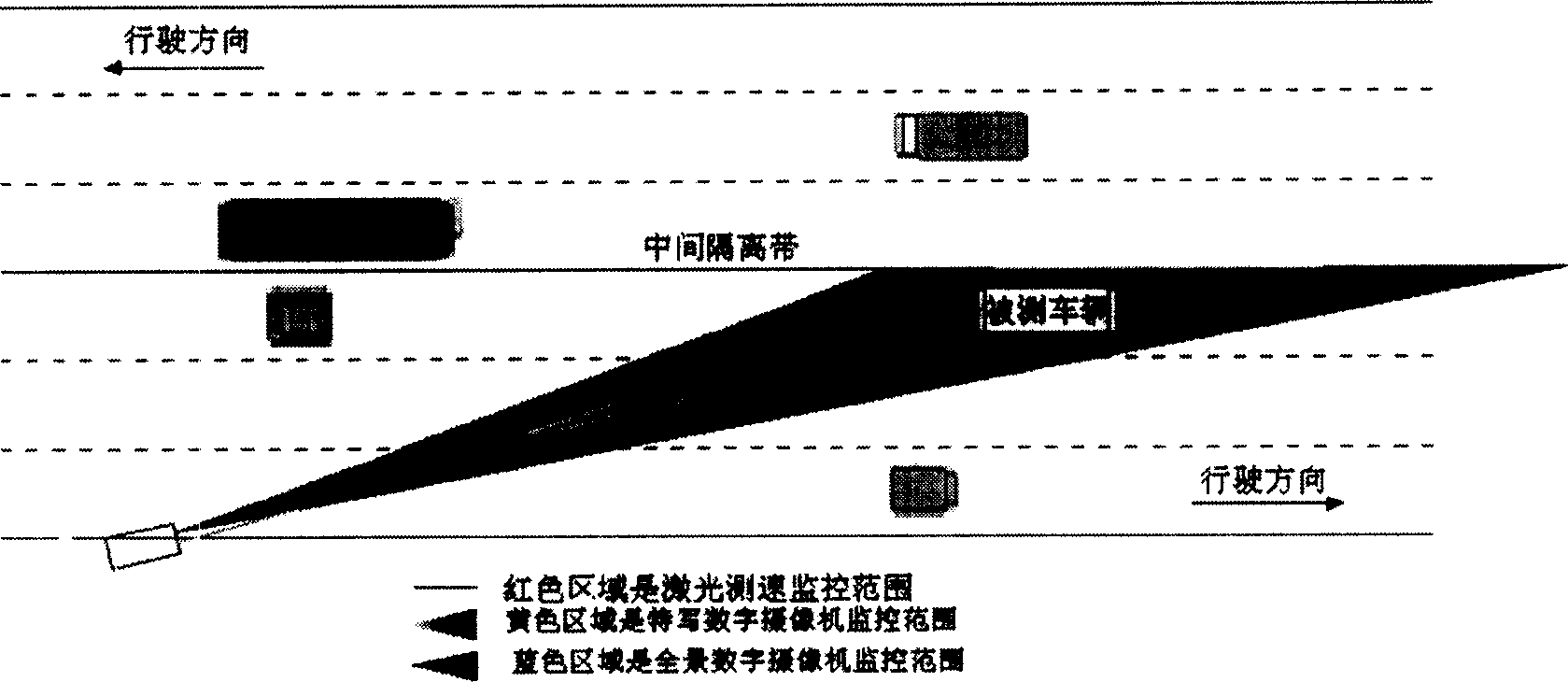

All-weather two camera shooting laser speed measuring testification apparatus

InactiveCN1909014AImprove clarityEasy to carryTelevision system detailsRoad vehicles traffic controlClose-upPhysics

The disclosed all-weather dual-camera laser speed measuring and quoting device comprises: a laser speed velometer and a color digital camera both on one side of the case, and a controller connected with former pieces by wire, wherein the included angle between the velometer and camera is between 0deg and 0.075deg, the camera composes by a close-up digital camera and an overall digital camera arranged from upper to lower, and the velometer composes by a laser emitter and a receiver. This invention applies its controller to operate the cameras for fast and accurate images, and fit to all weather work.

Owner:李佳欣

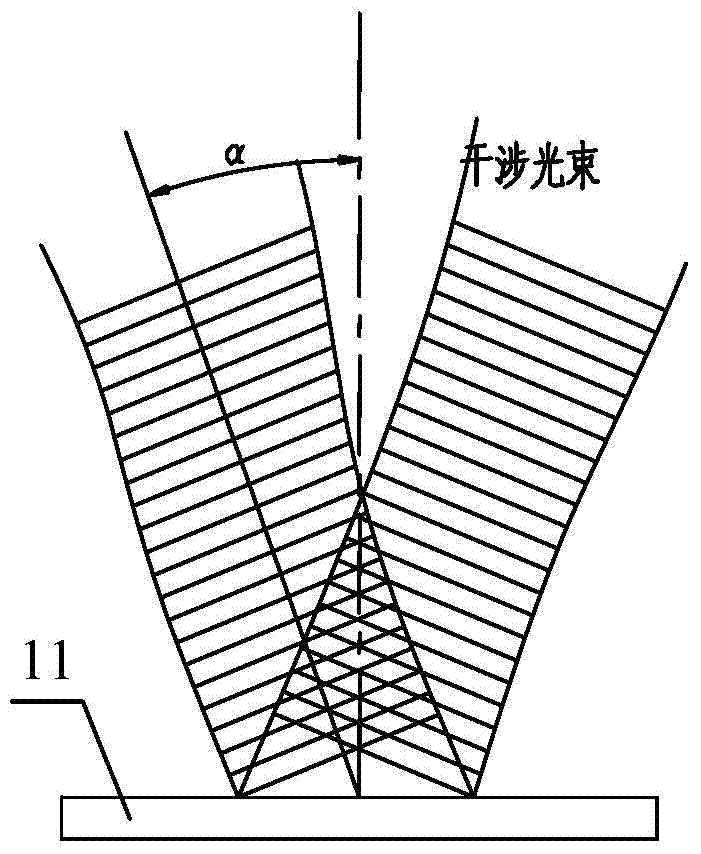

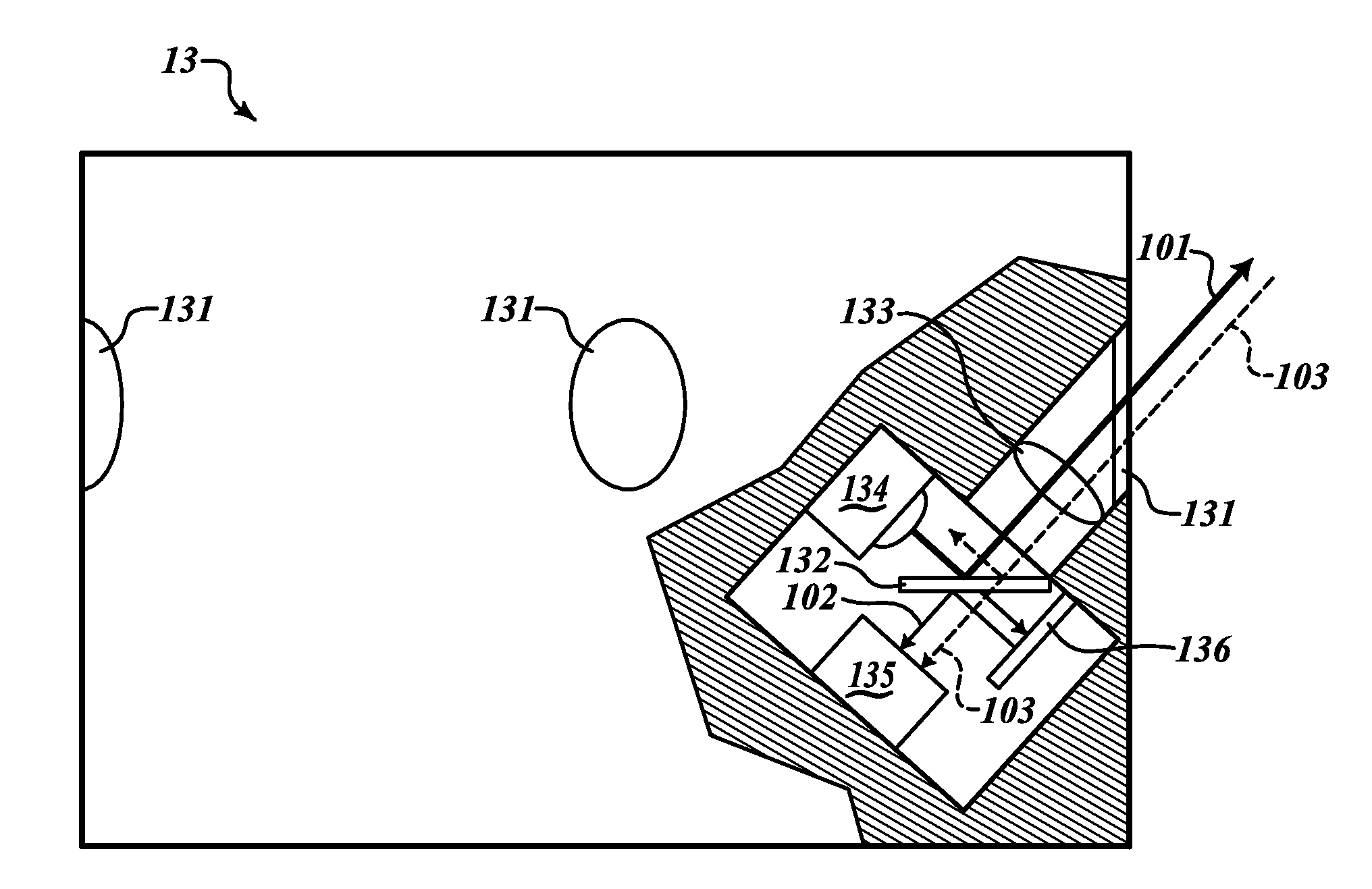

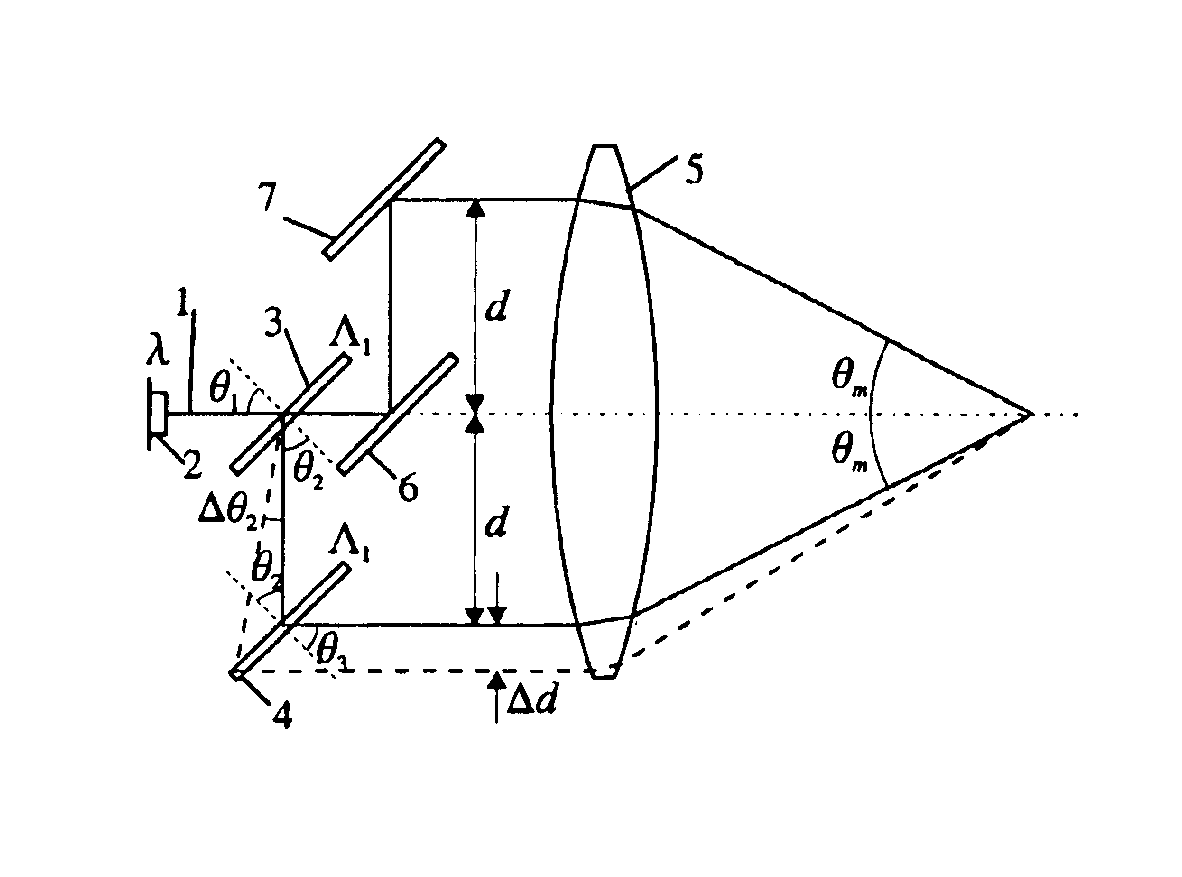

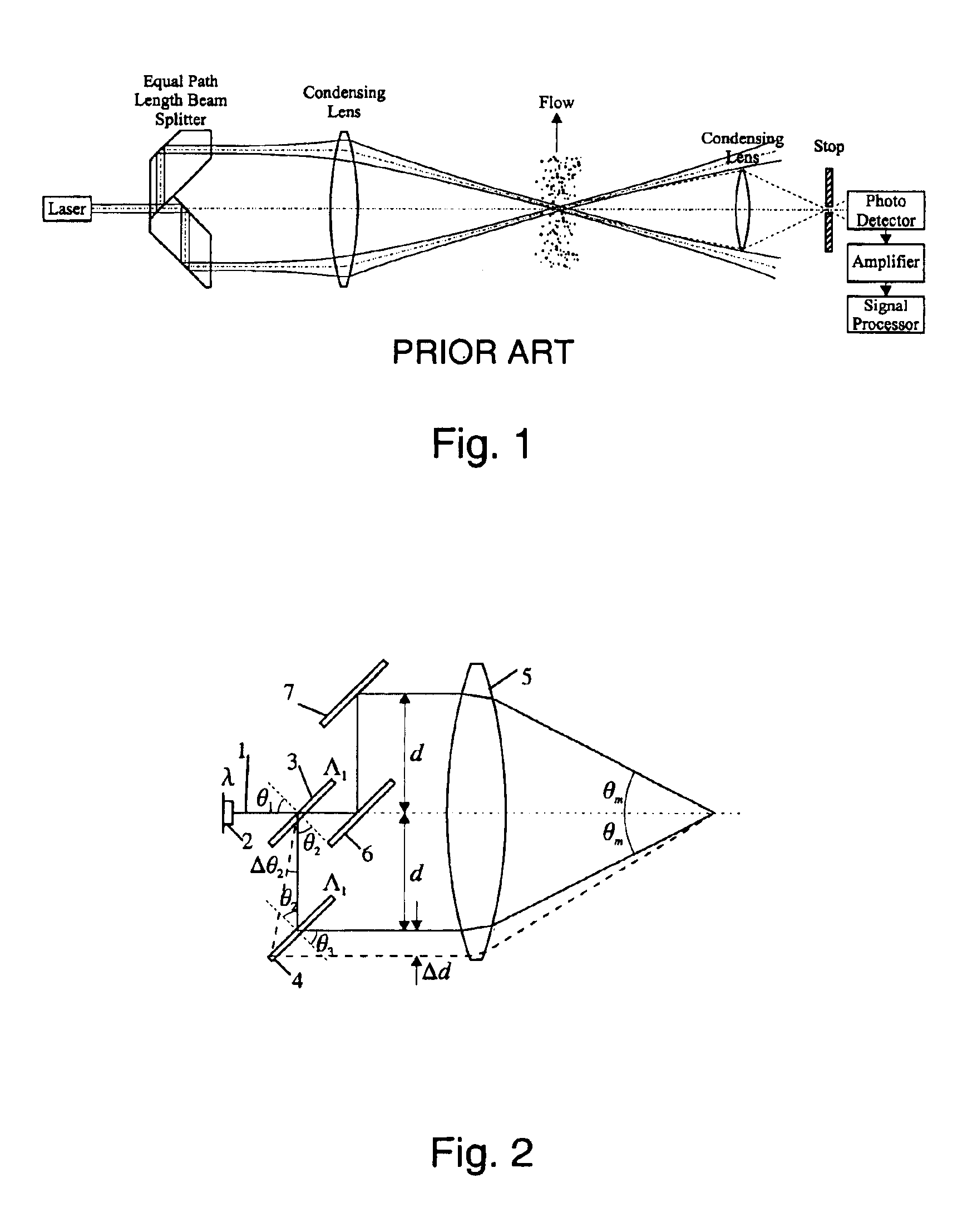

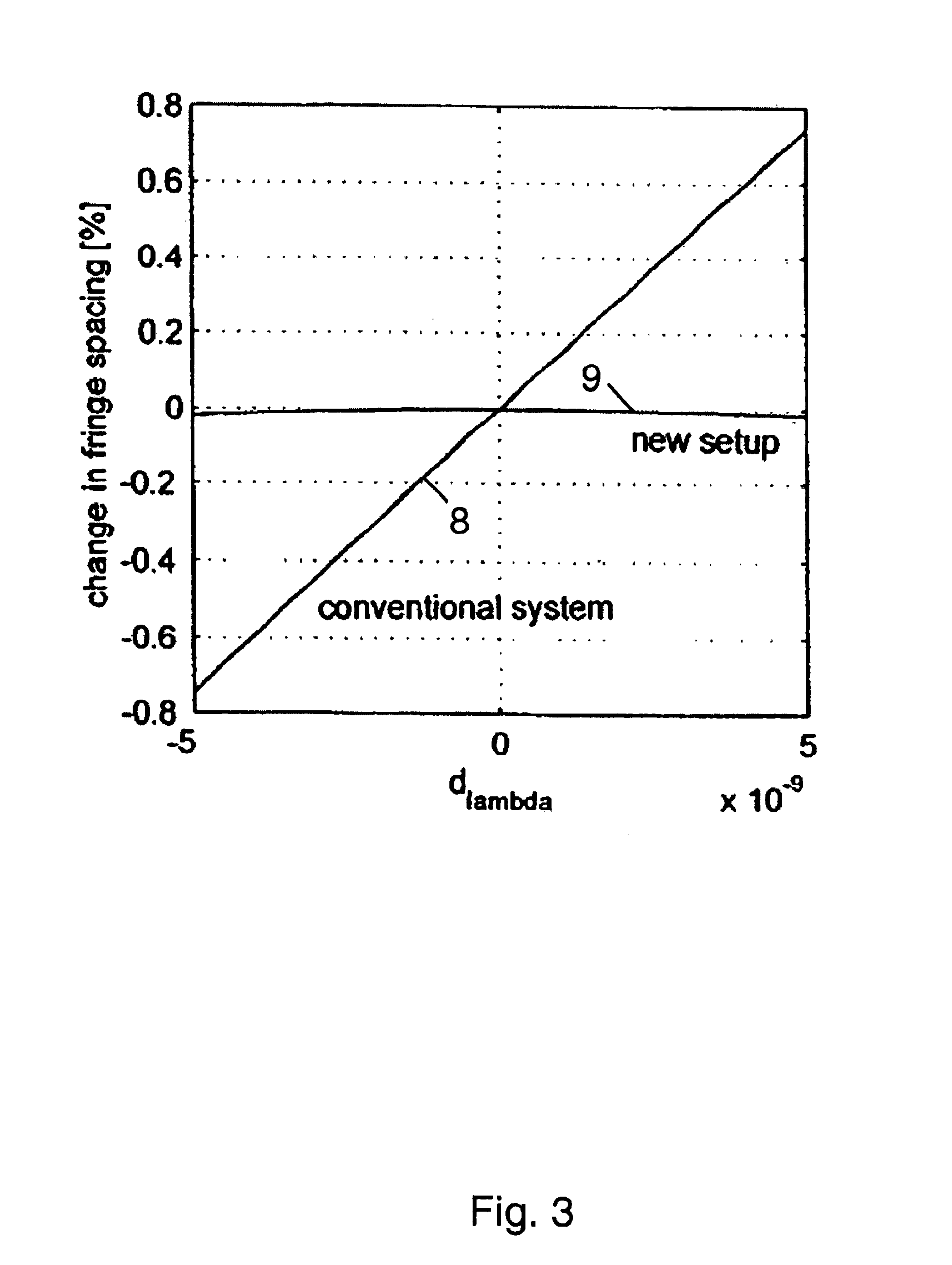

Laser doppler anemometry with diffractive optical elements

InactiveUS6859267B2Large scaleLow costAcceleration measurement using interia forcesParticle size analysisBeam splitterLight beam

The present invention relates to an apparatus for use in the determination of a condition or state of an object based on quasi-elastic interaction between the object and light transmitted to the object, the apparatus comprising a beam splitter arrangement for splitting an incoming light beam of wavelength, λ, into a diffracted light beam and an undiffracted light beam, the beam splitter arrangement comprising a first and a second diffractive member, the first diffractive member transforming the light beam emitted by the light source into the diffracted and the undiffracted light beams, the second diffractive member receiving the diffracted light beam and diffracting the received light beam in a direction substantially parallel to the undiffracted light beam from the first diffractive member, wherein the diffracted light beam, after being diffracted by the second diffractive member, and the undiffracted light beam from the first diffractive member are separated by a distance, d, said distance, d, being dependent on wavelength, λ.

Owner:KAMSTRUP

Control method of actual speed for cutting tail end of band steel by flying shear of 2250-mm rolling mill

ActiveCN105598169ASolve the problem of flying shear tail instabilitySolve instabilityRoll mill control devicesMeasuring devicesMeasuring instrumentMaterials science

The invention provides a control method of an actual speed for cutting a tail end of band steel by a flying shear of a 2250-mm rolling mill and belongs to a control technology of cutting the tail end of the hot-rolled band steel by the flying shear in a metallurgy industry. According to the control method, two metal hot detection devices arranged in front of the flying shear are included. The control method is characterized in that a laser speed measuring instrument is arranged between the two metal hot detection devices; the actual speed V of the band steel is equal to V1*Vlaser / V2+VT, wherein V1 is an actual speed of F1 when the band steel leaves away from the laser speed measuring instrument and VT is equal to -0.02 to 0.022; Vlaser is a band steel speed detected by the laser speed measuring instrument when the band steel leaves away from the laser speed measuring instrument; and V2 is an actual speed of the frame F1 when the band steel leaves away from the metal hot detection device on the rear side. With the adoption of the control method provided by the invention, the shearing stability of the flying shear is improved, the fault rate is obviously reduced and good benefits are obtained.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

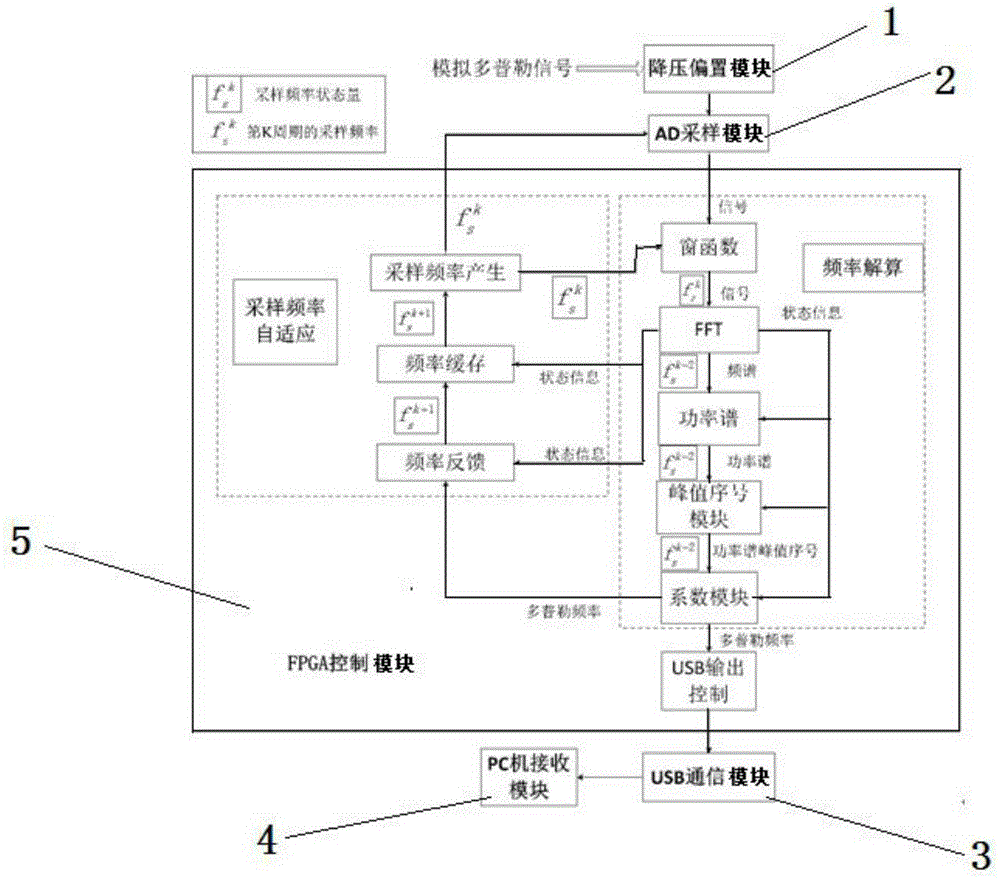

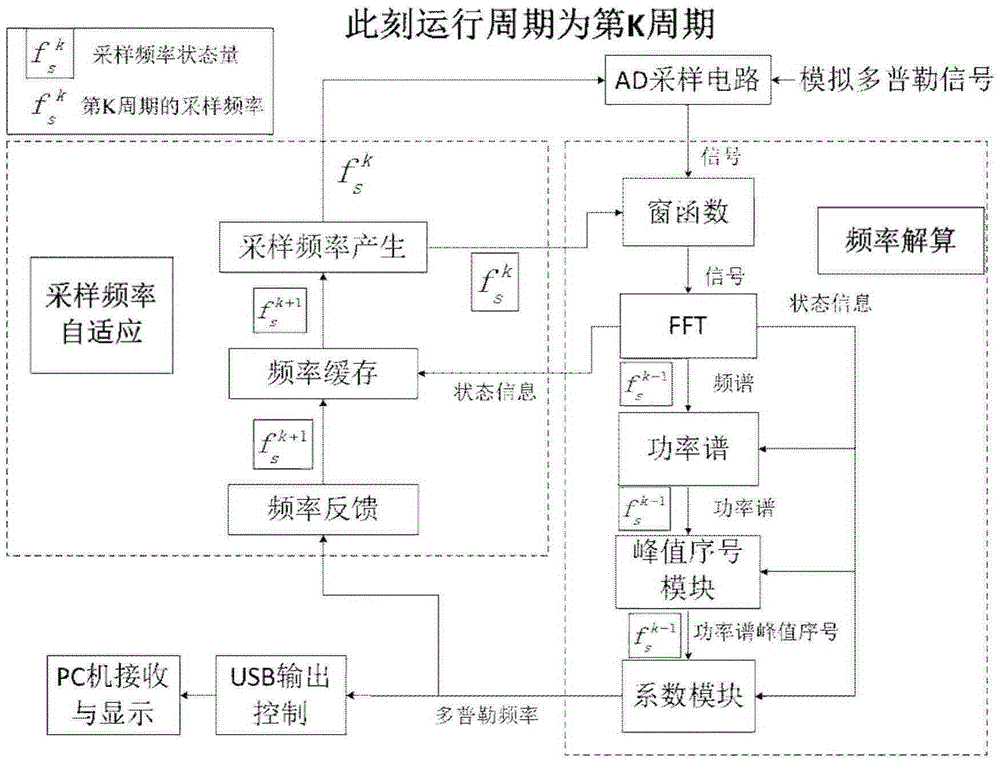

Signal processing system based on FPGA laser tachymeter and method

InactiveCN105277947AReduce flowReduce processing timeElectromagnetic wave reradiationAnti jammingUSB

The invention discloses a signal processing system based on an FPGA laser tachymeter and a method. After power is on, FPGA sends a sampling clock to an AD sampling module. After FPGA receives data sampled by AD, the data are processed in real time. A processing result is transmitted to a PC for storage and display through USB. According to the invention, data flow between two core chips is eliminated; the data processing time can be effectively reduced; the chance of exposing the data to the outside world is reduced; the anti-jamming capability of the data is increased; a lot of time to store the data can be saved; the signal processing time is reduced to the greatest extent; the data processing delay is reduced; the timeliness is improved; the system and the method are adaptive to signals in different frequency bands, and take into account the measurement accuracy and measurement range; and a USB transmission mode is used, so that data transmission is stable.

Owner:NAT UNIV OF DEFENSE TECH

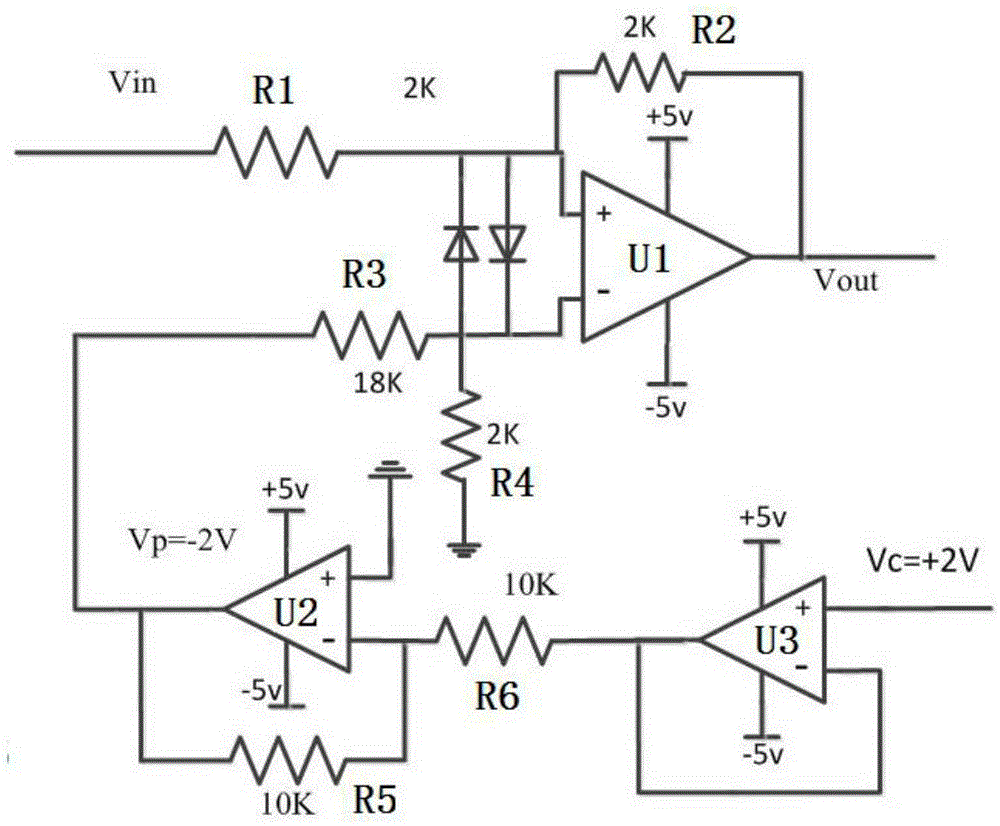

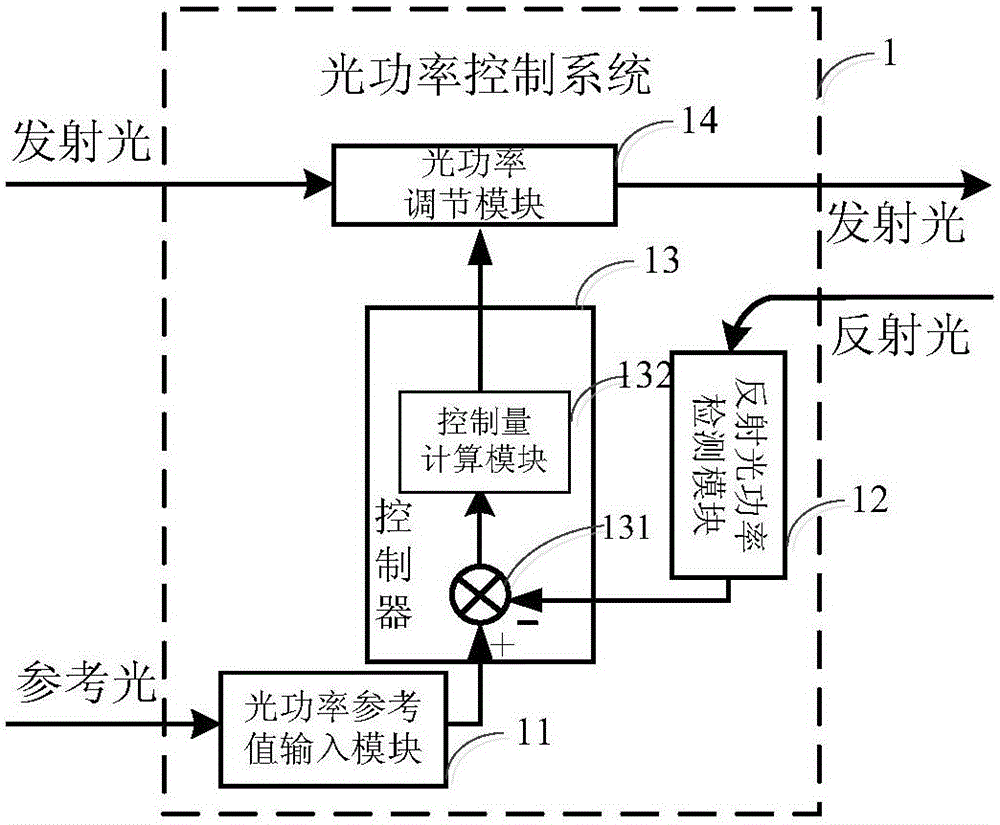

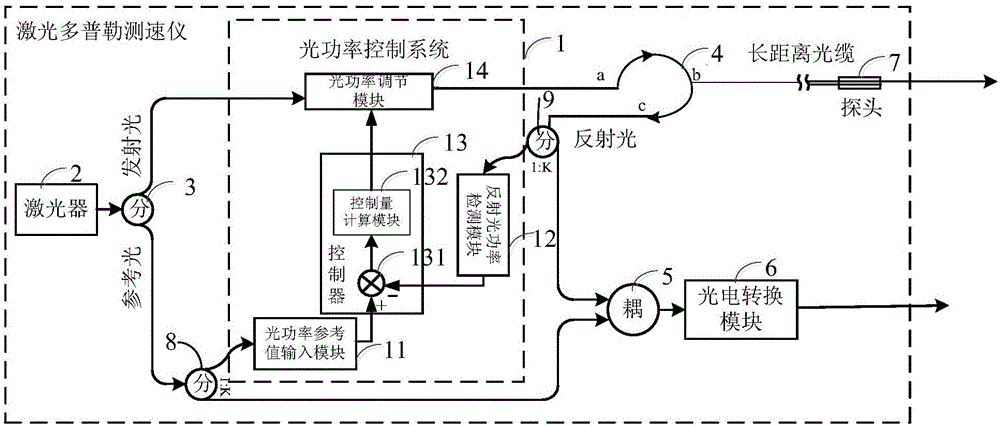

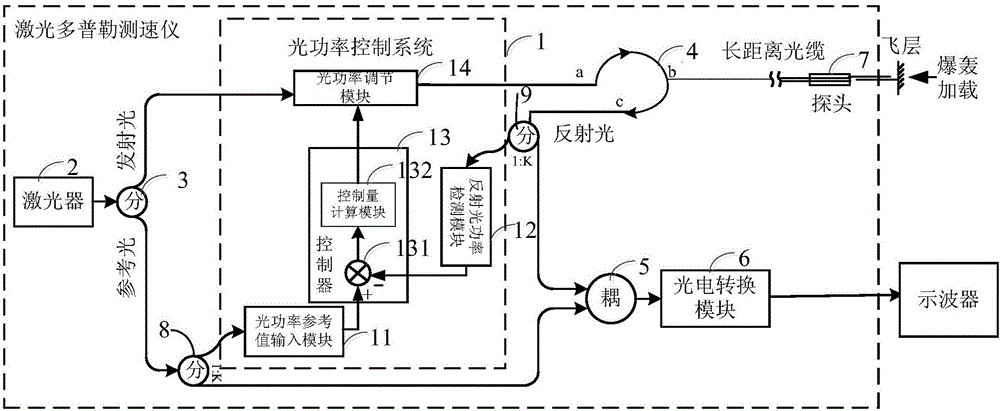

Optical power control system, control method and laser Doppler velocimeter

ActiveCN105842705AReduce Sensitivity Setting MarginImprove signal to noise ratioElectromagnetic wave reradiationOptical power meterSignal quality

The invention relates to the technical field of photoelectric transient state testing and provides an optical control system, a control method and a laser Doppler velocimeter. The optical control system includes an optical power reference value input module, a reflected light power detection module, a controller and an optical power adjusting module. According to the technical scheme provided by the invention, dynamic adjustment of emitted light power can be performed according to the change of reflected light power, so that the reflected power is kept constant and is equal to or in a fixed proportion with the reference light power; amplitude stability and base line stability of coupling interference signals of reflected light and reference light can be ensured; a condition that a to-be-detected object can reflect light of sufficient power can be ensured; testing signal quality can be improved; signal-to-noise ratio of signals can be improved; and a phenomenon of signal loss caused by too weak reflected light can also be inhibited; and the testing reliability is improved.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

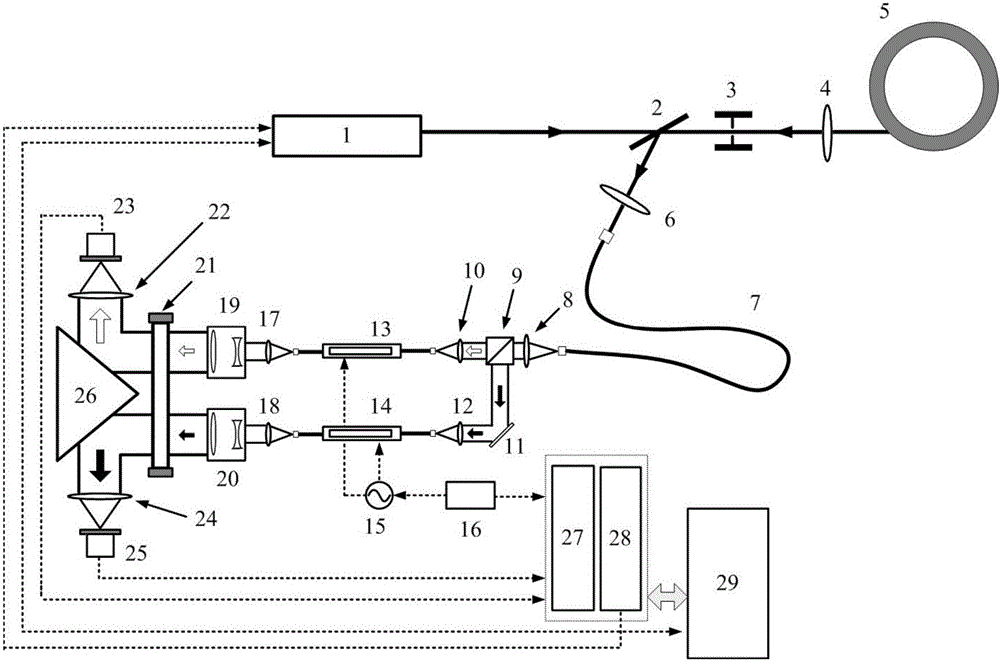

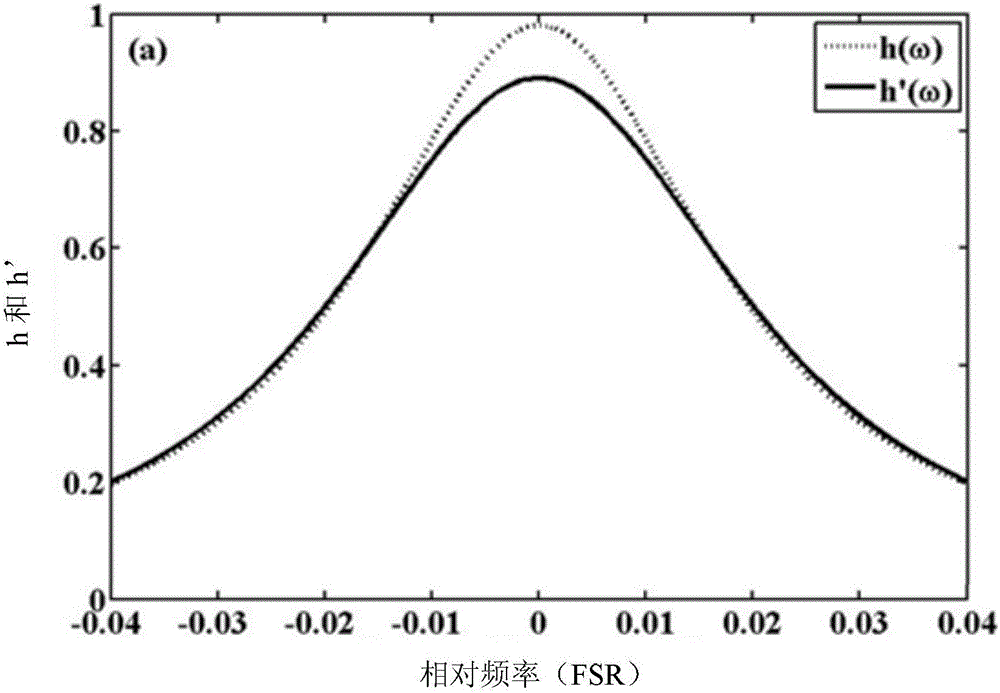

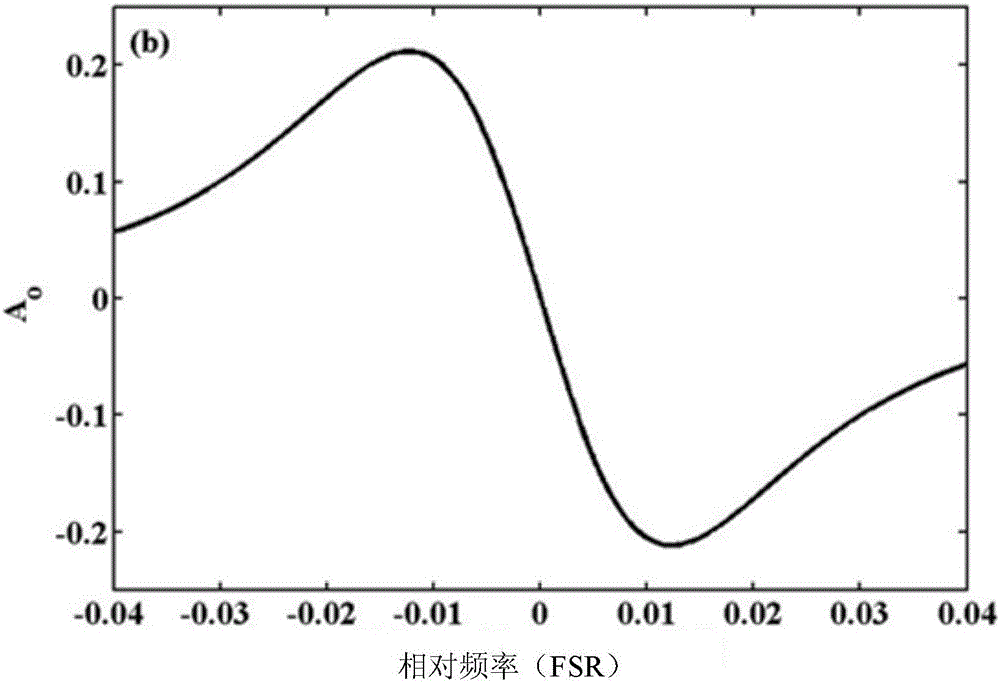

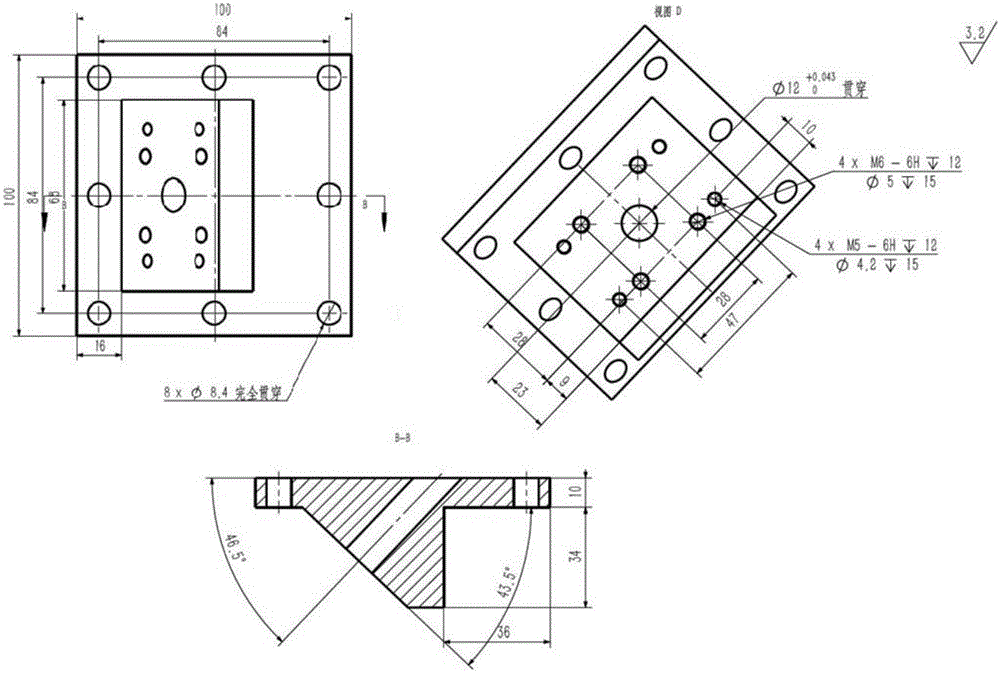

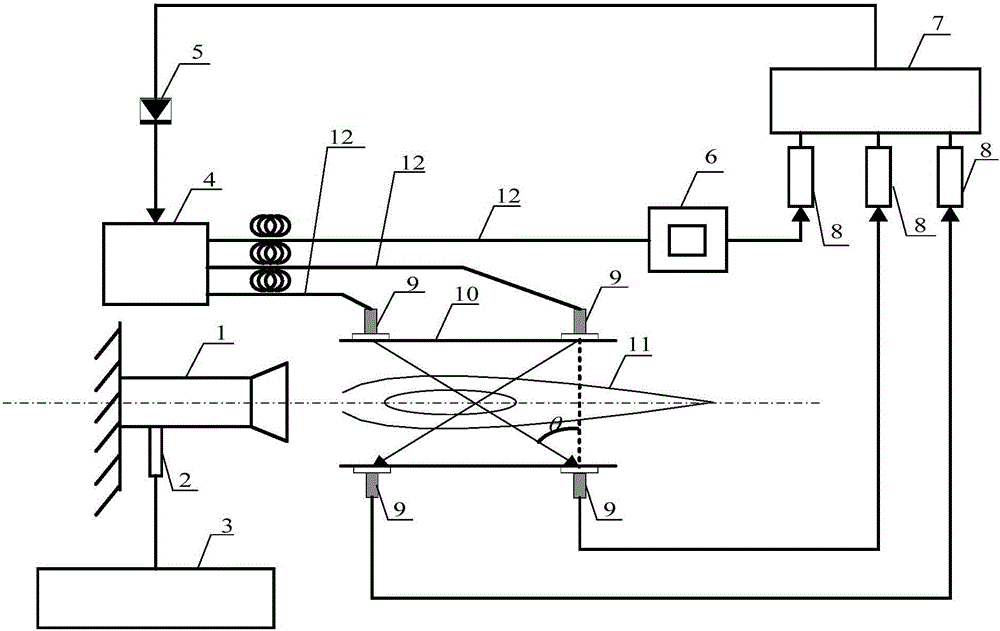

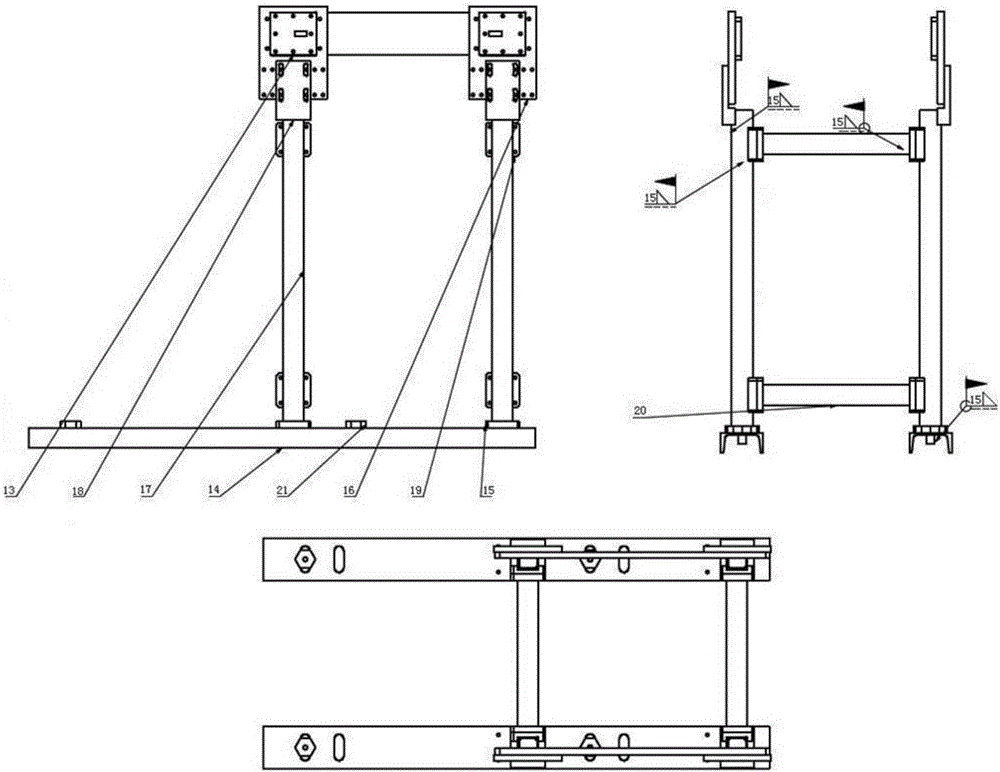

Double-margin phase modulation laser Doppler velocimetry system and method

InactiveCN105759281AWide frequency shift measurement rangeHigh measurement sensitivityElectromagnetic wave reradiationPhotomultiplierPrism

The invention discloses a double-margin phase modulation laser Doppler velocimetry system and method and relates to the Doppler velocimetry technique. The problems of existing phase modulation laser Doppler velocimetry systems that Doppler shift information in a signal light double modulation frequency beat frequency signal phase can not be utilized simultaneously and Doppler shift information in all echo signal light can not be fully utilized are solved. A polarization splitting prism is adopted for dividing echo signal light into two beams according to position, sinusoidal phase modulation is conducted on all signal light beams in the same way, and detection is conducted on all signal light beams with photomultipliers respectively. Two frequency discrimination parameters lA1(omega) and lA2(omega) are obtained through two current values i1 and i2, and by means of the two frequency discrimination parameters lA1(omega) and lA2(omega), a new frequency discrimination parameter sA(omega) is established to serve as the frequency discrimination parameter of the double-margin structure, wherein sA(omega)=lA1(omega)-lA2(omega). The system and method are suitable for double-margin phase modulation laser Doppler velocimetry.

Owner:HARBIN NORMAL UNIVERSITY

Propellant charge exhaust plume flow velocity measurement apparatus

InactiveCN105866468AAccurate measurementReduce the impact of measurement accuracyFluid speed measurementControl systemData acquisition

The invention discloses a propellant charge exhaust plume flow velocity measurement device, which solves the problem that the existing laser Doppler velocimeter and particle image velocimeter can only measure the particle velocity in the fluid, rely on tracer particles and cannot be accurately characterized Fluid velocity issues. The invention includes a tunable semiconductor laser, a laser control system, an optical system, and a data acquisition and processing unit. The invention can realize the measurement of the exhaust plume flow velocity of the solid, liquid, colloid and paste propellant charge within the high precision and wide velocity measurement range (0-3000m / s). The invention is applicable to the measurement of the flow velocity of the exhaust plume generated when different kinds of propellants are burned in the engine, and has important significance for the optimization of the propellant composition, the design of the propellant charge and the design of the engine.

Owner:XIAN MODERN CHEM RES INST

Doppler signal period distribution demodulation method of laser Doppler velocimeter

InactiveCN102236092AImprove processing accuracyEliminate frequency shift calculation errorsElectromagnetic wave reradiationInstabilityLaser Doppler vibrometer

The invention discloses a Doppler signal period distribution demodulation method of a laser Doppler velocimeter. The time domain processing principle based on a period counting method is adopted, the average frequency in all periods in each set time period is not calculated, but the time value distribution of each period in each time period is analyzed, and the most frequent time value in the time value distribution is taken as the period length in the time period and is converted into the signal frequency in the time period. The Doppler signal period distribution demodulation method has the main advantages of improving the calculation precision of Doppler frequency shift signal processing and effectively reducing the influence of widening or narrowing of the Doppler frequency shift signal period, losing of part of signals and noise, which are caused by the instability of the scattered light, on the test result of the target movement velocity.

Owner:XIAN MODERN CHEM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com