Secondary-projection-algorithm-based on-line non-contact contour detection system and method of intermediate-thick plate

A contour detection, non-contact technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of inaccurate contour information, limiting the application range of contour detectors, and inability to detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

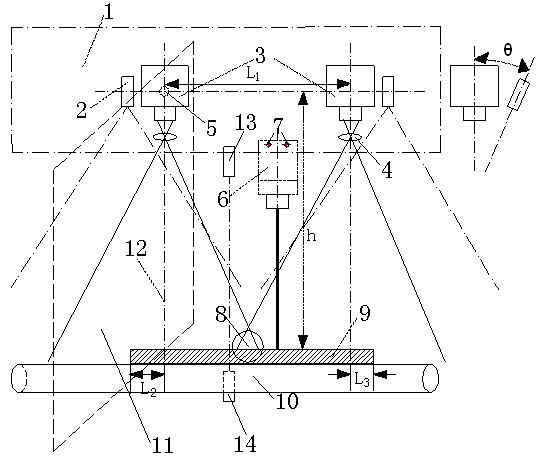

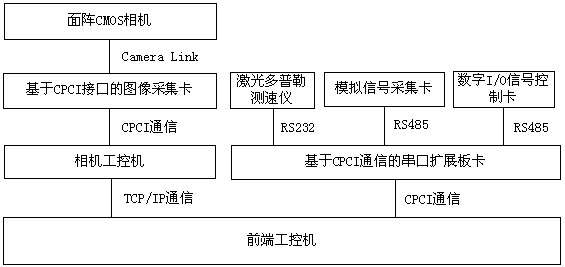

[0053] Such as figure 1 , 2 As shown, the online non-contact plate profile detection system based on the re-projection algorithm includes a plate profile detection device and a control device;

[0054] The medium and thick plate profile detection device includes sensor cabinet 1, line laser source 2, area array CMOS camera 3, camera lens 4, installation position of area array CMOS camera 5, laser Doppler velocimeter 6, screw 7, two adjacent surface The visual overlapping area 8 of the array CMOS camera, the measured strip steel 9, the strip steel conveying roller table 10, the plane 11 formed by the camera axis and the camera installation point, the axis 12 of the left array CMOS camera, the photoelectric switch receiver 13 and the photoelectric switch transmitter 14;

[0055] The sensor cabinet 1 is provided with two area-array CMOS cameras 3 on the same height plane, and a camera lens 4 is installed on the area-array CMOS camera 3, and a plurality of line laser sources 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com