Method for measuring length of steel plate

A technology of steel plate and length measurement, applied in measuring devices, instruments, and optical devices, etc., can solve the problems of complicated devices and affecting production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

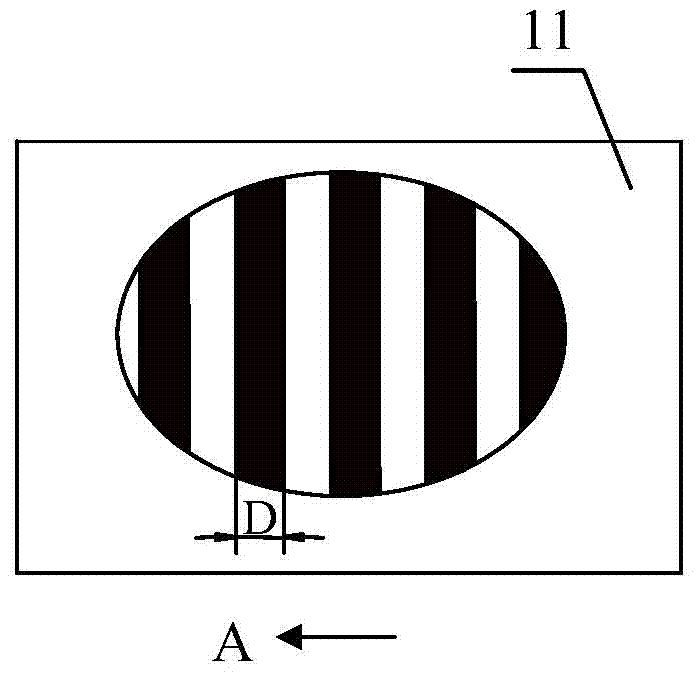

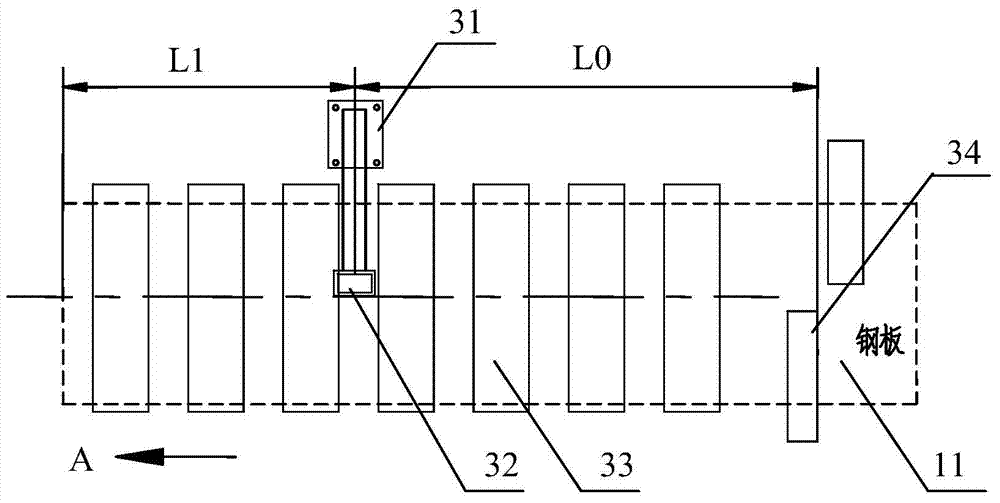

[0041] The method for measuring the length of the steel plate of the present invention refers to the measuring method for the length of the sheared steel plate by cutting the head in the steel plate rolling line, see image 3 - Figure 4 , in the steel plate rolling line equipment, a laser velocimeter 32 is installed at the exit position of the shears, specifically, the laser velocimeter 32 is installed in the exit direction of the shears and away from the lower cutting edge of the shears 34 On the fixed bracket 31 at the distance L0, L0 must be smaller than the minimum section size of the steel plate 11.

[0042] Right below the laser velocimeter 32 ( Figure 4 In the direction shown by the dotted line with double dots), a reflective plate 41 is installed below the conveying roller table 33, and the reflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com