A liquid beverage filling valve

A valve and beverage technology, used in liquid bottling, liquid processing, fluid distribution valves, etc., can solve problems such as position offset, liquid outflow, inability to control liquid speed, etc., and achieve the effect of uniform flow rate and stable flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

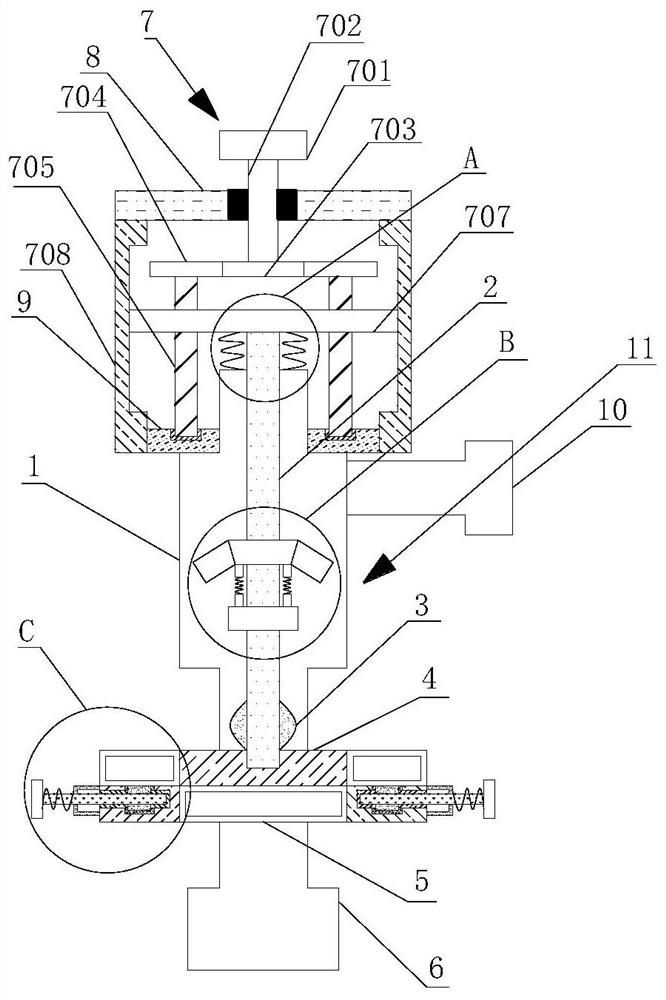

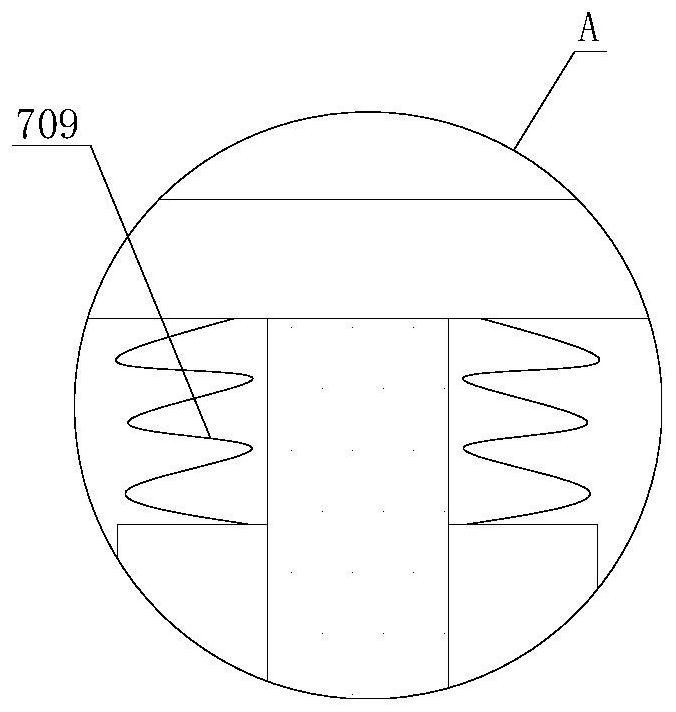

[0025] Examples of the described embodiments are illustrated in the accompanying drawings, wherein the same or similar reference numbers represent the same or similar throughout

[0026] In the present invention, unless otherwise expressly specified and limited, the terms "installed", "connected", "connected", "fixed", etc.

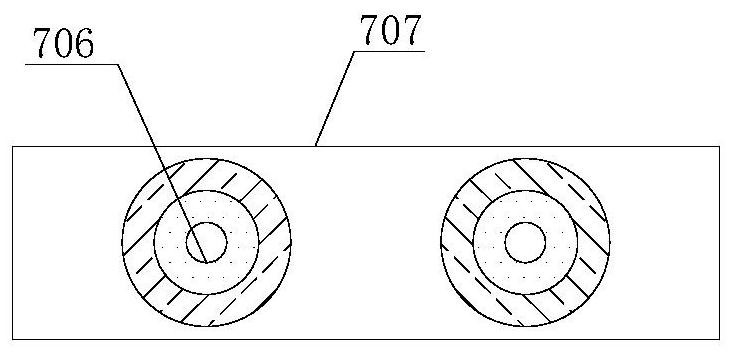

[0029] The adjustment mechanism 7 includes a knob 701, a connecting shaft 702, a first gear 703, a second gear 704, a threaded rod 705, a thread

[0033] Although embodiments of the present invention have been shown and described, it will be apparent to those of ordinary skill in the art that

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com