Fixing structure for assembly type glass handrail

A technology for glass railings and fixed structures, applied in railings, railings, stepped structures, etc., can solve the problems of increasing hidden dangers, unable to meet the needs of use, and not being reminded of glass cracks in time, so as to reduce hidden dangers and avoid Shaking damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

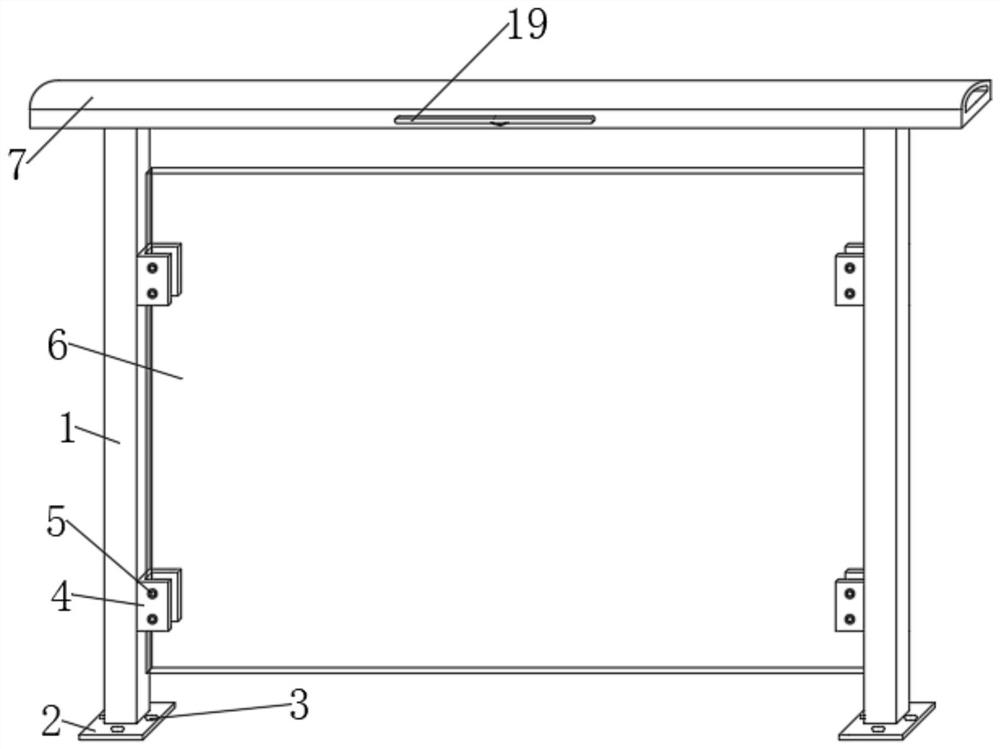

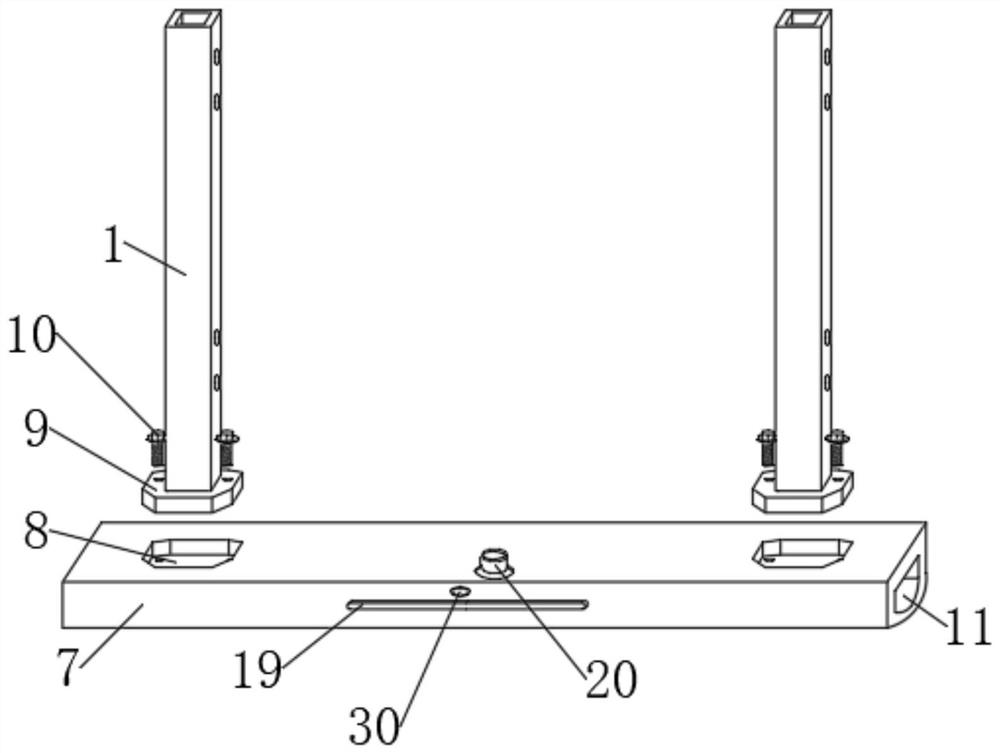

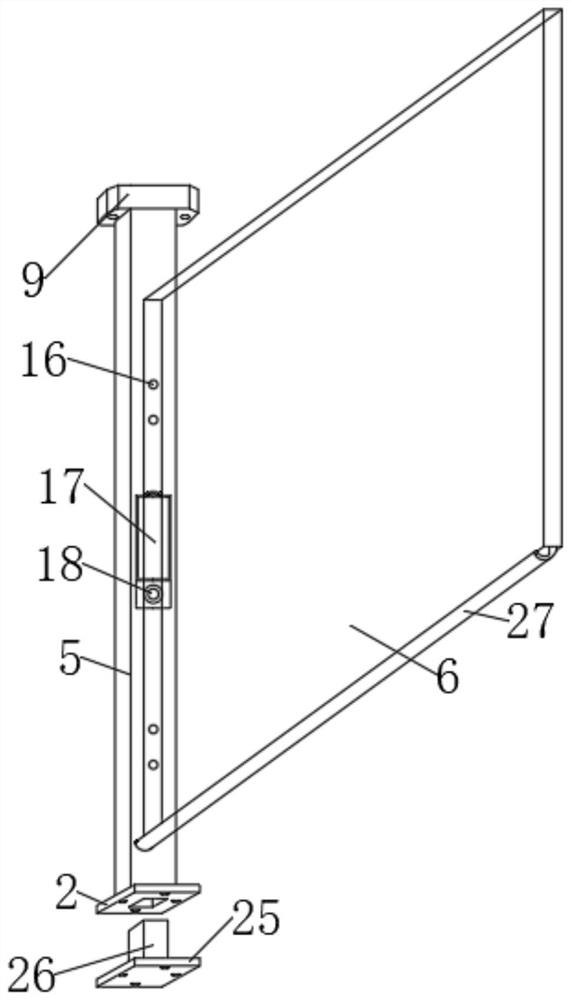

[0026] Such as Figure 1-5 As shown, the embodiment of the present invention provides a fixed structure for a prefabricated glass railing handrail, including a fixed vertical bar 1, a glass clip 4 and a handrail bar 7, the lower side of the handrail bar 7 is vertically provided with a fixed vertical bar 1, and the fixed vertical bar A glass clip 4 is arranged on the opposite side wall of the rod 1, and a battery box 17 is arranged on the side wall of the fixed vertical bar 1 at the center between the upper side glass clip 4 and the lower side glass clip 4, and the lower side of the battery box 17 is provided with a refractive index Sensor 18, warning light bar 19 is arranged on the outer symmetrical side wall of handrail bar 7, loudspeaker 30 is arranged at the position of handrail bar 7 on the lower side of the center of warning light bar 19, and projection decorative light 20 is arranged on the lower side of handrail bar 7, and projection decorative light The upper end of 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com