Crack monitoring equipment and test equipment for automobile fatigue test

A fatigue test and monitoring equipment technology, applied in the direction of applying repeated force/pulsation force to test material strength, measuring devices, instruments, etc., can solve the problem of stopping the test, prolonging the fatigue life of the sample, and unable to achieve real-time monitoring of crack initiation and expansion, etc. problems, to achieve the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

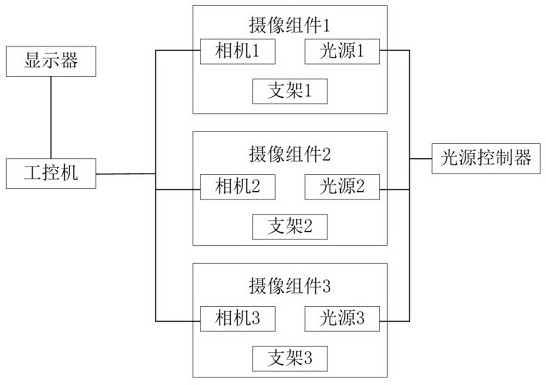

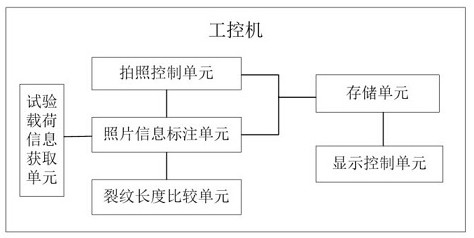

[0023] This Example 1 provides a crack intelligent monitoring system for fatigue testing of automobile chassis components, such as figure 1 As shown in, a light source controller, a industrial computer, a display, and at least one imaging component are included. The number of the imaging assembly is selected according to the test demand of the automotive chassis component fatigue test. In this embodiment, three imaging assemblies (e.g., in other embodiments can be 1, 2, 4, 5, 6, 7) 8, 9, 10, 11, 12, 13-72, etc.). Each of the imaging assemblies includes a camera, a light source, and a bracket, a camera, and a light source, all of which are mounted on the bracket, the camera, the light source, and the bracket is assembled together, according to the test demand of the fatigue test of the automotive chassis components. The location of the camera assembly is installed. Once the camera is a fixed focus lens, the crack length, and the photo pixel are determined, only the calibration leng...

Embodiment 2

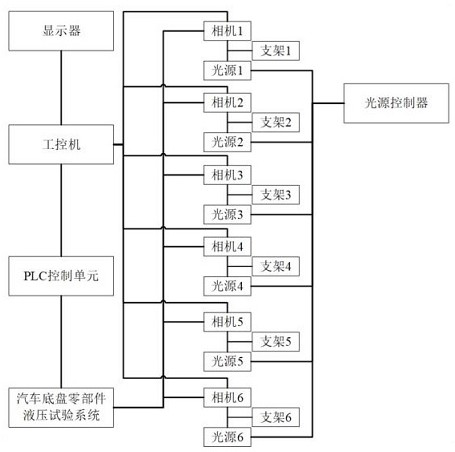

[0032] In this Example 2, a test equipment for automotive chassis component fatigue test, such as image 3 The display, industrial computer, PLC control unit, automotive chassis component hydraulic test system, camera, light source, bracket, light source controller, display and industrial control, there is information interaction between the industrial control and the PLC control unit Information interaction, PLC control unit and the automotive chassis component hydraulic test system, the light source controller and the light source are connected to the light source, the camera and the light source are integrated together, the stent supports the fixed camera and the light source, the camera and the industrial computer There is information interaction between information interaction, the camera takes a sample crack photo of the fatigue test of the car chassis parts.

[0033] The light source controller is electrically connected to the light source, and the light source controller fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com