Slip form system suitable for construction of variable-diameter variable-cross-section cylinder structure

A variable cross-section, cylinder technology, applied in the field of sliding form system, can solve complex sliding form construction and other problems, and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Structural drawings further illustrate the present invention.

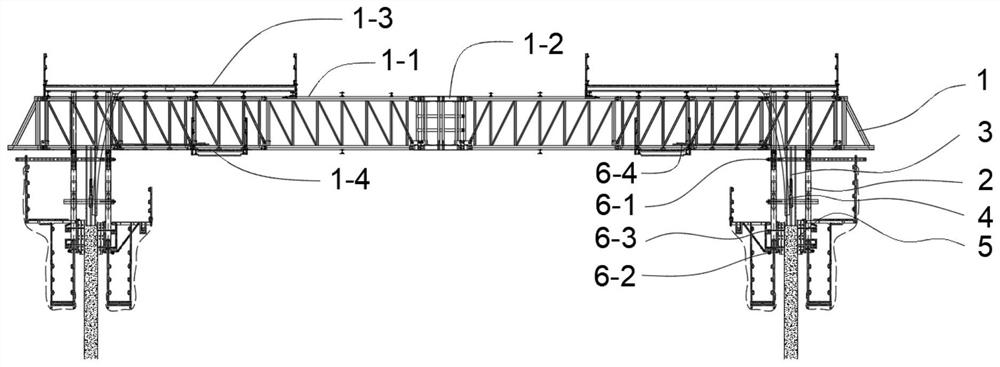

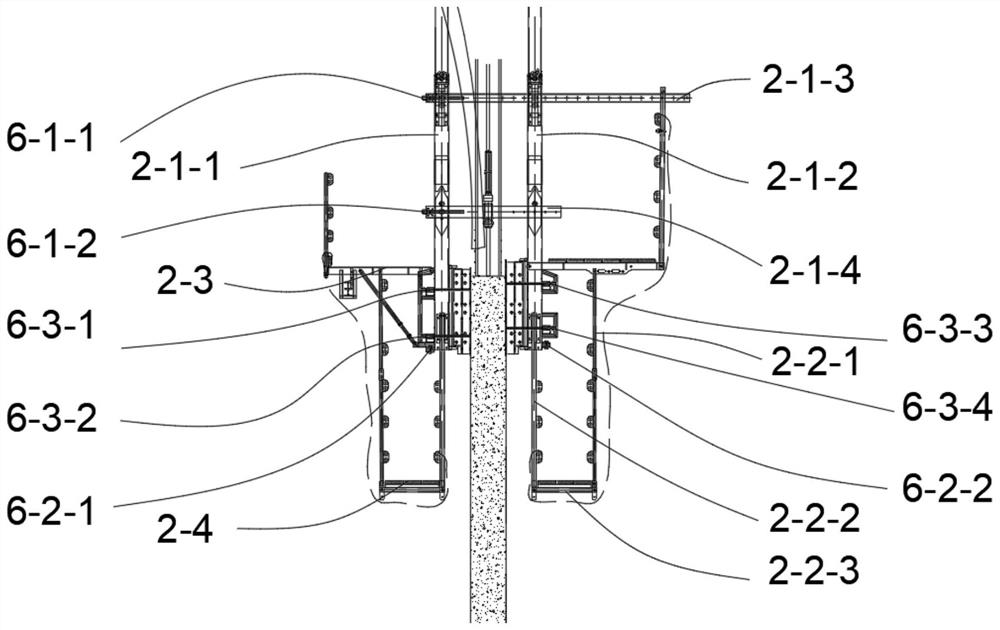

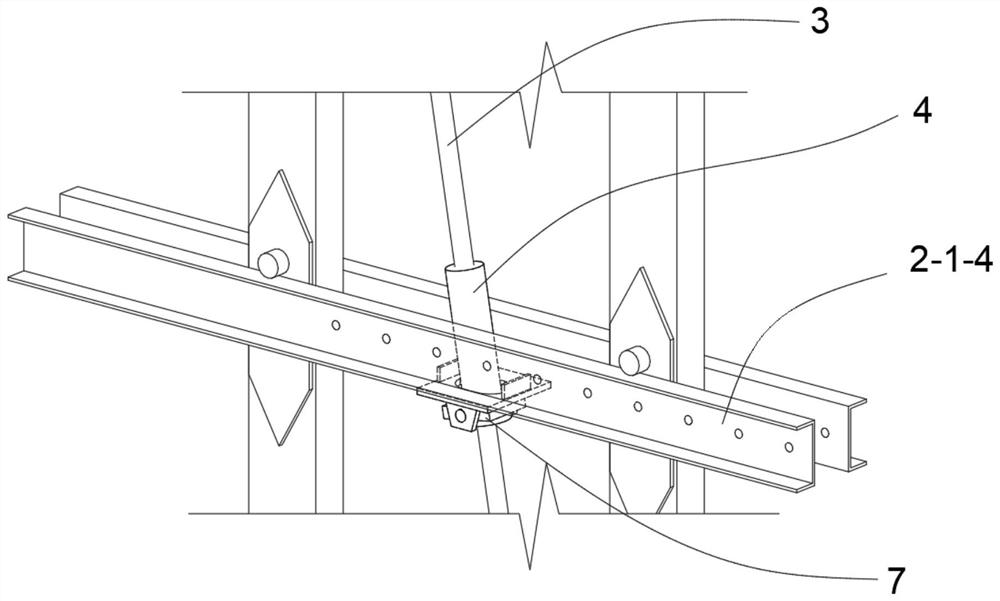

[0023] Such as figure 1 As shown, a sliding form system suitable for the construction of variable-diameter and variable-section cylindrical structures includes: steel truss platform 1, gantry system 2, support rod 3, jack 4, formwork system 5, and adjustment system 6. The gantry system 2 supports the steel truss platform 1 , which is connected to the support rod 3 by the jack 4 . The formwork system 5 is attached to the portal frame 2 .

[0024] The steel truss platform 1 is formed by connecting a plurality of radial steel trusses 1-1 and a central drum ring 1-2, and uses I-beams to connect between the steel trusses 1-1. A plurality of steel trusses 1-1 on both sides of the central drum ring 1-2 respectively form steel truss pieces. The portal frame can slide between the steel trusses 1-1 of the steel truss sheets on both sides respectively. The steel truss platform 1 also includes a top floor operating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com