Stable speed reducer device easy to disassemble and assemble for lathe

A kind of reducer, easy disassembly and assembly technology, applied in the direction of transmission parts, mechanical equipment, belts/chains/gears, etc., can solve the problem that the reducer does not have an excellent installation and adjustment device, and is inconvenient to adjust various levels. Improve mechanical transmission efficiency, improve space utilization, and cooperate with compact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

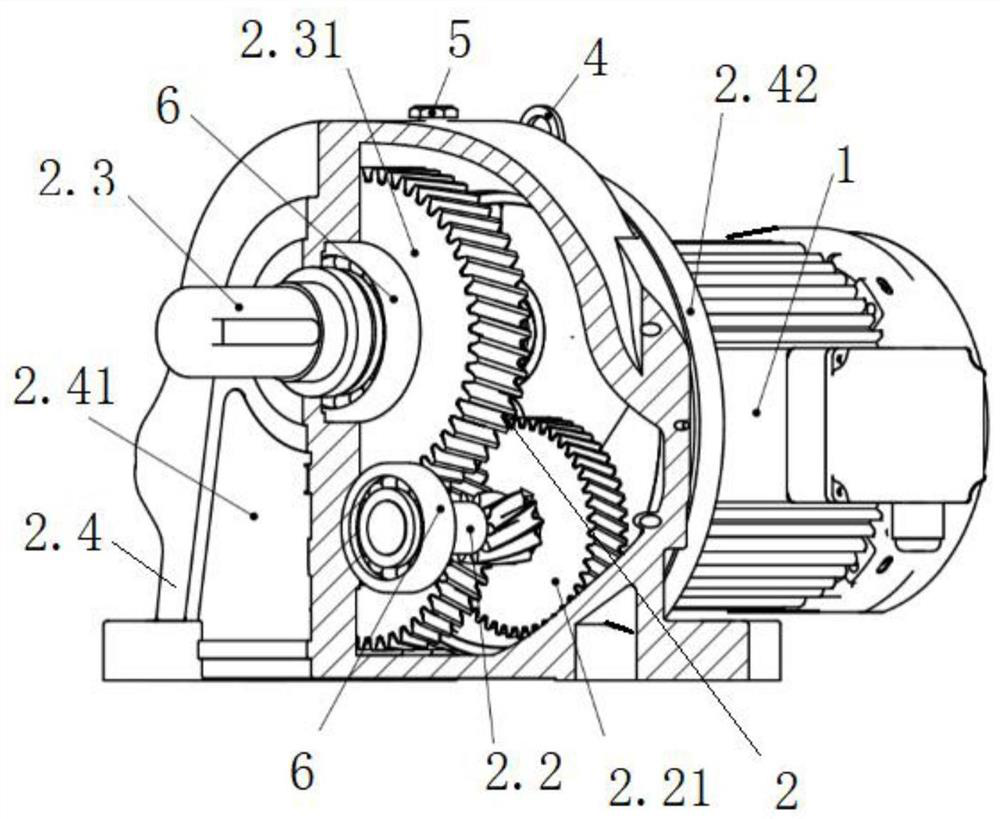

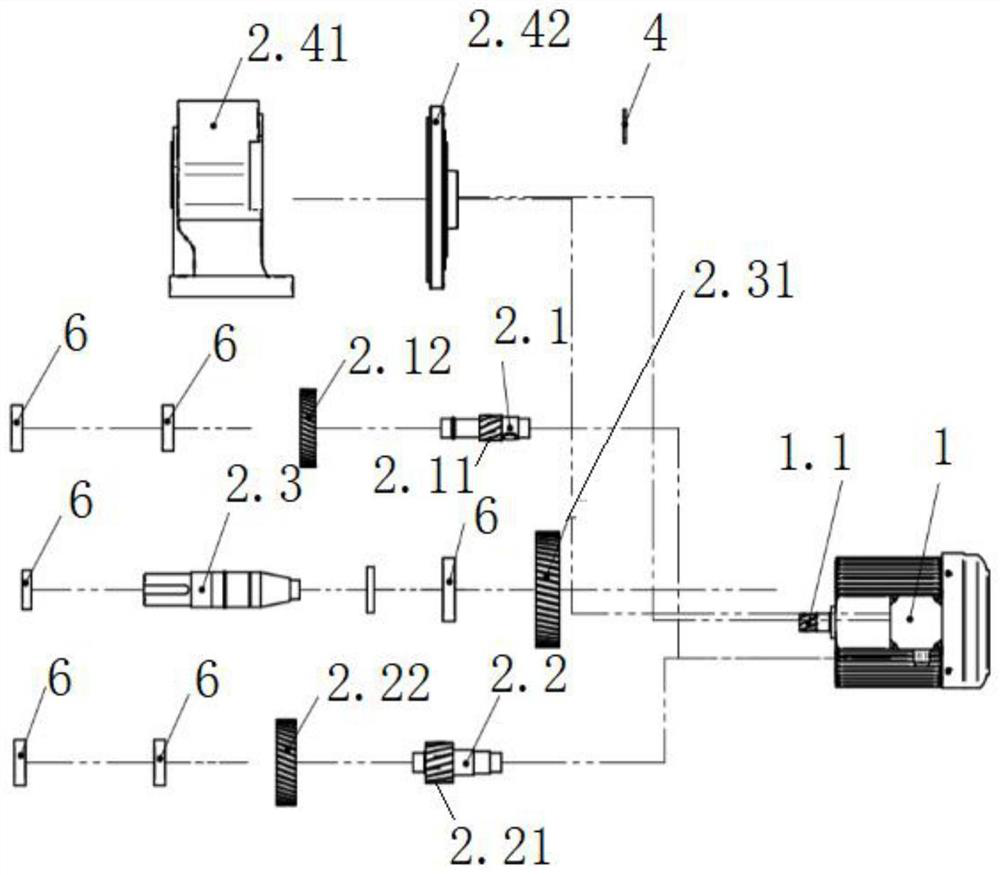

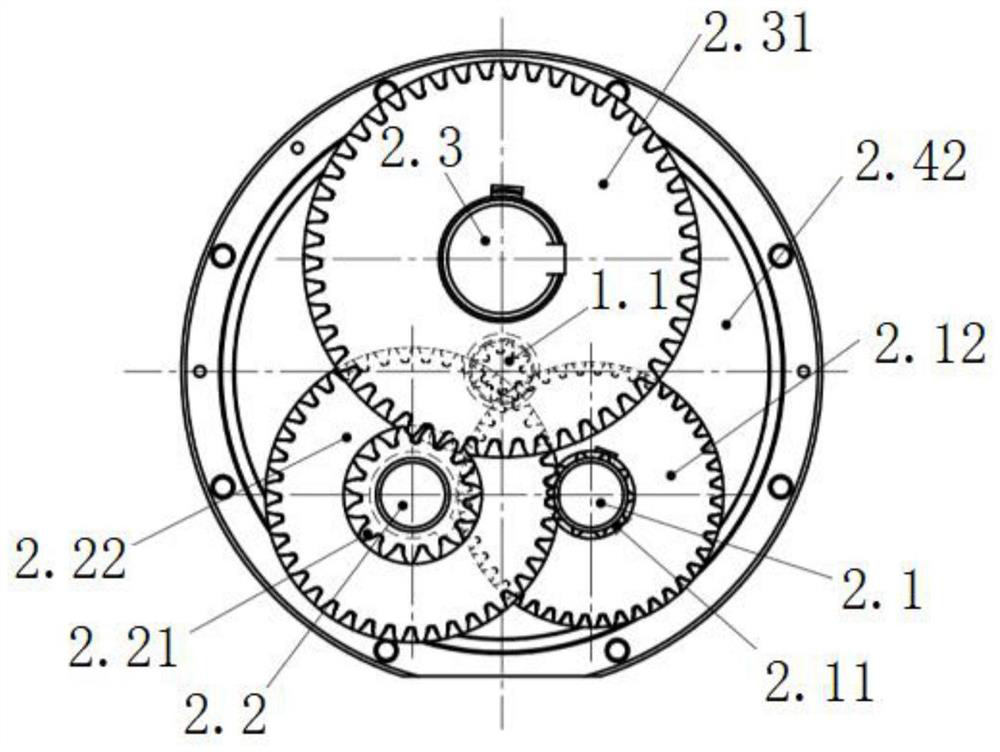

[0034] A stable and easy-to-disassemble reducer device for lathes, such as Figure 1-6 As shown, it specifically includes the drive device 1 and the reducer 2, see Figure 1-2 ,Details are as follows:

[0035] The output shaft of the drive device 1 is provided with a main drive gear 1.1, and the drive device can be a motor.

[0036] The speed reducer 2 includes a first gear shaft 2.1, a second gear shaft 2.2, a third gear shaft 2.3 and a housing 2.4, and the structure and connection relationship of each part are as follows:

[0037] The housing 2.4 is a box structure with a housing cavity formed by detachable connection of the box body 2.41 and the box cover 2.42. Here, it is preferred that one end of the box cover 2.42 is connected with the drive device 1 by bolts, and the box cover The other end of 2.42 is connected with box body 2.41 by bolts. Said box cover 2.42 is equipped with suspension ring 4 (preferably triangular suspension ring) through bolt holes and bolts. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com