A replacement tool and replacement method for replacing horizontally arranged cross-arms of tension poles with electricity

A technology of horizontally arranged and tension-resistant poles, applied in the direction of overhead lines/cable equipment, towers, building types, etc., can solve problems such as insufficient space and insufficient safety distance, and achieve reliable power supply, simple disassembly, and flexible and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

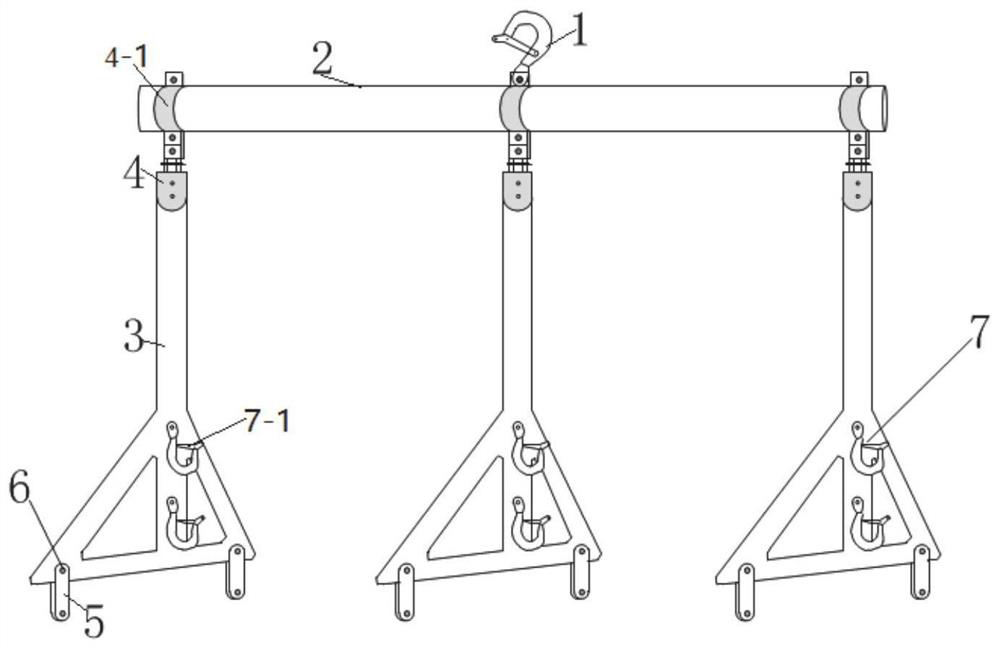

[0030] In the technical solutions disclosed in one or more embodiments, such as figure 1 As shown, a replacement tool for replacing horizontally arranged cross-arms of tension poles with electricity, including horizontal insulating cross-arms 2 and vertical insulating cross-arms 3, and the vertical insulating cross-arms 3 are sequentially arranged in horizontal positions according to set intervals. Horizontal and lateral arrangement is realized on the insulating cross arm 2;

[0031] The lower end of each vertical insulating cross arm 3 is provided with at least two adjustable connecting plates 5 with a set distance apart, and the adjustable connecting plates 5 are used for fixed connection with the tension insulator connection hanging plate.

[0032] This embodiment uses the horizontal insulating cross arm 2 and the vertical insulating cross arm 3, the horizontal insulating cross arm is used to provide a horizontal support structure, the vertical insulating cross arm is used ...

Embodiment 2

[0048] Based on the tool in Embodiment 1, this embodiment provides a method for replacing the cross-arm of horizontally arranged tension poles with electricity, including the following steps:

[0049] Step 1. Disconnect the tension insulator connection plate on the line from the original cross arm, use the replacement tool in Example 1 to connect the tension insulator connection plate, and fix the tension insulator connection plate to the insulator and the bow wire. And lift to the set height;

[0050] Step 2, replace the new cross arm, the replacement tool described in embodiment 1 will vertically drop the lifted wires, insulators and fittings to the original position;

[0051] Step 3. Turn the three-phase bow wires down to the original position; separate the tension insulator connection hanging plate from the tool described in Embodiment 1, and fix the tension insulator connection hanging plate on the new cross arm.

[0052] When the line is not powered off, the tool of Emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com